Polyurethane foam resin and preparation method thereof

A technology of foaming resin and polyurethane, which is applied in the field of polyurethane foaming resin, can solve the problems of unsuitable treatment of water-based materials, synthetic leather, high cost of foaming resin, and potential safety hazards, etc., and achieve excellent hand feeling and comprehensive effect, and good adhesion , good breathability and moisture permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

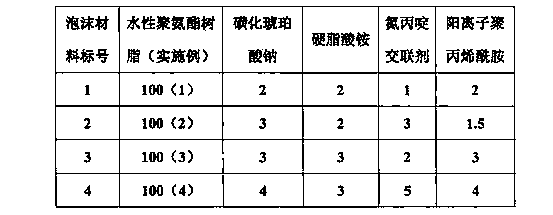

Examples

Embodiment 1

[0043] Embodiment 1: waterborne polyurethane resin

[0044] Add 85g polyester diol (number average molecular weight 2000), 65g polytetrahydrofuran diol (number average molecular weight 1000), 42g toluene diisocyanate, 0.01g stannous octoate into the reaction vessel, and react under mechanical stirring at 60°C 3h; Dissolve 9.8g of dimethylolpropionic acid and 5.2g of trimethylolpropane in 15g of NMP, add to the mixture, and react at 70°C for 4h; cool down to 30°C, add 8g of triethylamine, 20g of acetone, and stir for 40min; Under high-speed stirring, 200 g of deionized water was added to the above reaction solution, and mechanically stirred for 50 min to form a dispersion. The solvent was then removed by distillation under reduced pressure. A milky white dispersion with a solids content of 49.8% was obtained.

Embodiment 2

[0045] Embodiment 2: waterborne polyurethane resin

[0046] Add 110g polyadipate type polyester diol (number average molecular weight 1000), 65g isophorone diisocyanate, 0.04g dibutyltin dilaurate into the reaction vessel, and react at 75°C for 1.5h under mechanical stirring ;Dissolve 10.5g dimethylolpropionic acid, 6g trimethylolpropane, 3g1,4-butanediol in 18g NMP, add to the mixture, react at 85°C for 2h; cool down to 40°C, add 8g triethylamine, 22g of acetone, stirred for 30min; under high-speed stirring, 200g of deionized water was added to the above reaction solution, and mechanically stirred for 45min to form a dispersion. The solvent was then removed by distillation under reduced pressure. A milky white dispersion with a solids content of 52% was obtained.

Embodiment 3

[0047] Embodiment 3: waterborne polyurethane resin

[0048] Add 250g polycarbonate diol (number average molecular weight 2000), 65g diphenylmethane diisocyanate, 0.06g organic bismuth into the reaction vessel, and react at 85°C for 2h under mechanical stirring; 8.5g dimethylol Dissolve propionic acid, 3.8g trimethylolpropane, 3g neopentyl glycol in 23g NMP, add to the mixture, react at 80°C for 3h; cool down to 50°C, add 6.4g triethylamine, 20g acetone, stir for 40min; Under stirring, 270 g of deionized water was added to the above reaction liquid, and mechanically stirred for 1 h to form a dispersion. The solvent was then removed by distillation under reduced pressure. A milky white dispersion with a solids content of 55% was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com