Preparing method of chemical leather for lining of superfine fiber water absorption breathable shoes

A superfine fiber, moisture-permeable and breathable technology, applied in the field of synthetic leather preparation, can solve the problems of perforation, inconvenience in cutting, falling off, etc., and achieve the effects of good moisture-permeability, increased added value, and improved grades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

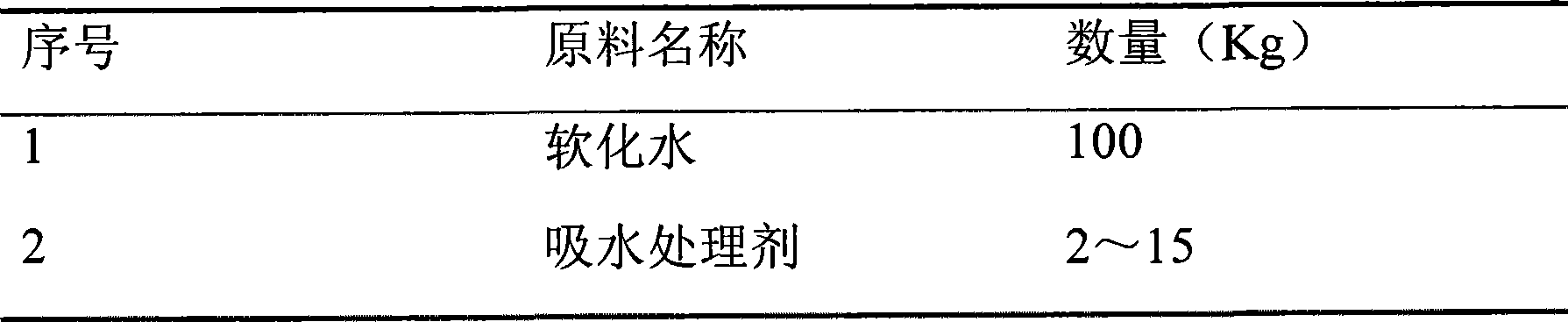

[0041] Select soft superfine fiber synthetic leather, according to the formula in Table 1, wherein the water absorption treatment agent is 10Kg, the temperature is 100 ℃, dry in a 30m length oven to prepare water absorption, moisture permeable and breathable superfine fiber synthetic leather base cloth .

Embodiment 2

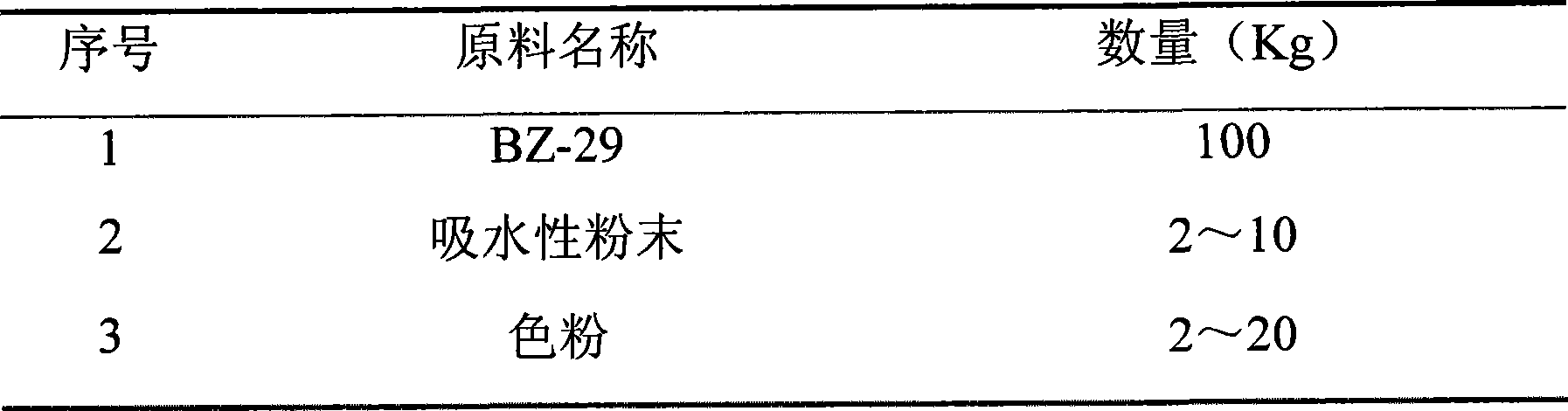

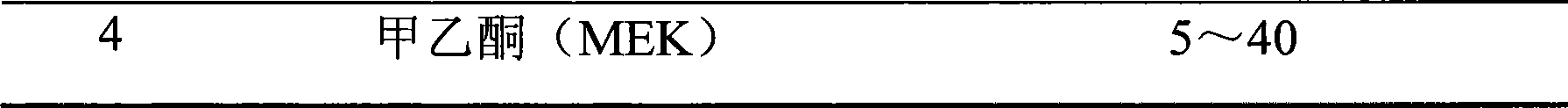

[0043] Adopt the base cloth of example 1 to carry out dry method face-making, its slurry formula is according to the proportioning in table 2 (wherein water-absorbing powder is 7Kg, toner is 6Kg, and MEK is 10Kg), adopts release paper B-100, a The coating drying temperature is 90°C, the knife distance is 220μm, the second coating knife distance is 150μm, the drying temperature is 120°C, the wet lamination is adopted, the bonding pressure is 4Kgf, the vehicle speed is 8m / min, and it is directly peeled off after drying. sample 1 # .

Embodiment 3

[0045] Adopt the base cloth of example 1 to carry out dry method face-making, its slurry formula is according to the proportioning in table 2 (wherein water-absorbing powder is 10Kg, toner is 6Kg, and MEK is 30Kg), adopts release paper B-100, a The coating drying temperature is 90°C, the knife distance is 200μm, and the second coating knife distance is 180μm. get sample 2 # .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com