Compound tissue functionality knitted fabric

A technology of knitted fabrics and composite structures, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of high production costs, complicated process conditions, stuffy body, etc., achieve super good washing durability and simple operation process , Good breathability and moisture permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

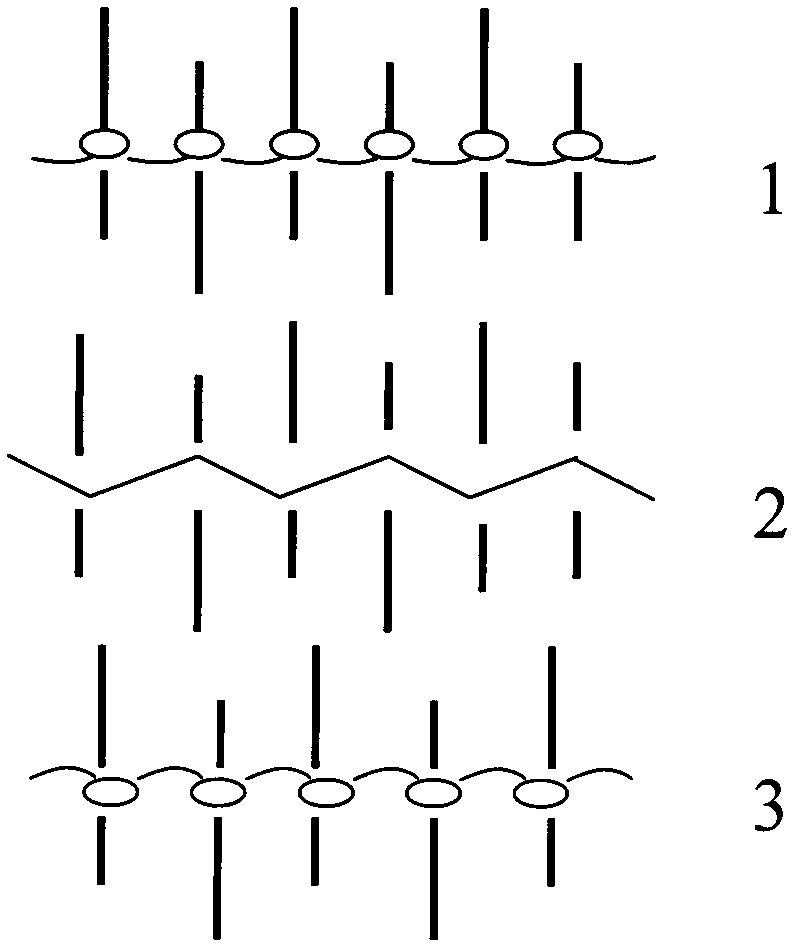

[0061] The outer coil is 75D-72f-PET yarn treated with hydrophobic resin, the middle coil is 20D-12f-PA yarn, and the inner coil is cotton yarn with a moisture regain of 8.5% and 50 counts, using a 24G Fukuhara double-sided machine Weaving, double-sided weave, weaves such as figure 1 , the horizontal and vertical density of the gray cloth is 35*43 pieces / inch, and the weight of the gray cloth is 145g / m 2 .

[0062] The gray cloth is finished by opening → gray cloth shaping → washing and scouring → dyeing → finishing and shaping. The shaping in this process is all wet cloth shaping, finishing and shaping can be properly added with resin according to needs to further improve the hand feeling; dyeing adopts the two-bath method: the first step The polyester component is dyed with disperse dye at 130°C, and the cotton component is dyed with direct dye at 60°C in the second step. Other processes are the same as conventional.

[0063] The obtained product has a horizontal and vert...

Embodiment 2

[0065] The outer coil is 50D-24f-PET yarn treated with hydrophobic resin, the middle coil is 20D-24f-ordinary PET yarn, and the inner coil is viscose yarn with a moisture regain of 13%, 50 counts and 20D- PU filaments are arranged in a ratio of 1:1, 24G Fukuhara double-sided machine weaving, double-sided weave, weave as figure 1 , the horizontal and vertical density of the gray cloth is 40*58 pieces / inch, and the weight of the gray cloth is 234.5g / m 2 .

[0066] The gray cloth is finished by opening → gray cloth shaping → washing and scouring → dyeing → finishing and shaping. The polyester component is dyed with disperse dye at 130°C, and the viscose component is dyed with direct dye at 60°C in the second step. Other processes are as usual.

[0067] The obtained product has a horizontal and vertical density of 41*64 pieces / inch, and a gram weight of 244g / m 2 . After washing 20 times, the water absorption time of the surface layer is more than 600 seconds, the water absorp...

Embodiment 3

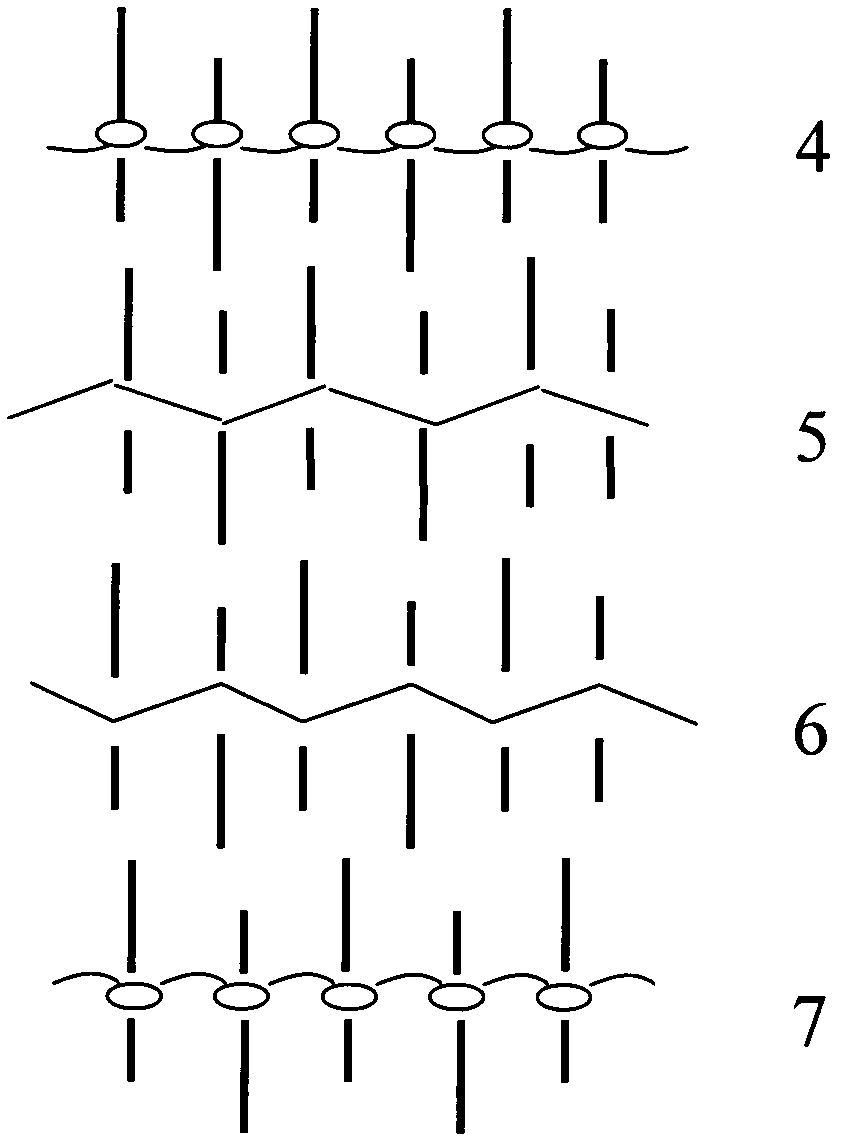

[0069] The outer coil is 150D-72f-PET yarn treated with hydrophobic resin, the middle coil is 50D-24f-ordinary PET yarn, and the inner coil is cupro fiber yarn with a moisture regain of 13% and 50D. Fukuhara double-sided machine weaving, double-sided weaving, weaving such as figure 2 , the horizontal and vertical density of the gray cloth is 42*63 pieces / inch, and the weight of the gray cloth is 192g / m 2 .

[0070] The gray cloth is finished by opening → gray cloth shaping → washing and scouring → dyeing → finishing and shaping to obtain the finished product. In this process, the shaping is done with wet cloth. Resin can be added to further improve the hand feeling after finishing and shaping; two-bath method is used for dyeing PET and copper respectively. Ammonia dyeing. Other processes are as usual.

[0071] The obtained product has a horizontal and vertical density of 34*47 pieces / inch, and a gram weight of 137g / m 2 . The surface layer has good hydrophobic properties....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com