Preparation method of porous nano fiber membrane

A technology of nanofiber membrane and dry membrane, which is applied in the direction of fiber chemical characteristics, rayon manufacturing, non-woven fabrics, etc. It can solve the problems of non-antibacterial, non-porous nanostructure, poor cell affinity, etc., and achieve cell Good affinity function, good breathability and moisture permeability, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

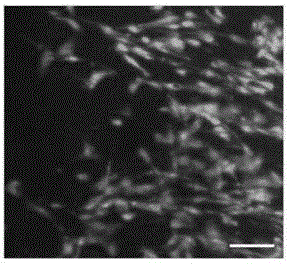

[0034] Disperse the washed 0.5 g flake graphene oxide in 9.5 g of anhydrous formic acid, and place it in an ultrasonic oscillator to vibrate for 2 hours to prepare a dispersion liquid in which graphene oxide is uniformly dispersed in anhydrous formic acid. The mass fraction of graphene oxide in the dispersion is 5%. Add 1.3 g of dried regenerated silk protein film to the above dispersion liquid, and stir for 2 h with a magnetic stirrer to obtain a uniform spinning liquid. The mass fraction of the regenerated silk protein dry film in the spinning solution is 11.5%. Adjust the working parameters of the electrospinning device: the voltage is 30kV, the flow rate of the spinning solution is 0.2mL / h, the distance between the spinneret and the collection device is 13cm, the above spinning solution is added to a 5mL glass syringe, and the electrospinning is carried out for 2h A porous nanofibrous membrane with a thickness of 0.5 mm is then obtained on the collection device.

Embodiment 2

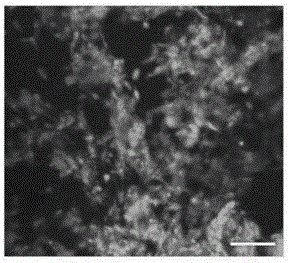

[0041]Disperse the washed 0.4 g flake graphene oxide in 9.5 g of anhydrous formic acid, place it in an ultrasonic oscillator and vibrate for 2 hours, and obtain a dispersion liquid in which graphene oxide is uniformly dispersed in anhydrous formic acid. The mass fraction of graphene oxide in the dispersion is 4%. Add 1.5g regenerated silk protein dry film in above-mentioned dispersion liquid, stir 2h by magnetic stirrer, obtain uniform spinning liquid. The mass fraction of the regenerated silk protein dry film in the spinning solution is 13%. Adjust the working parameters of the electrospinning device: the voltage is 20kV, the flow rate of the spinning solution is 0.3mL / h, the distance between the spinneret and the collecting device is 15cm, the above spinning solution is added to a 5mL glass syringe, and the electrospinning process is carried out for 2h A porous nanofibrous membrane with a thickness of 0.4 mm is then obtained on the collection device.

Embodiment 3

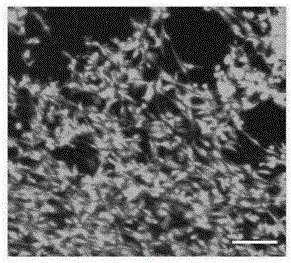

[0043] Disperse the washed 0.3 g flake graphene oxide in 9.5 g of anhydrous formic acid, and place it in an ultrasonic oscillator to vibrate for 2 hours to prepare a dispersion liquid in which graphene oxide is uniformly dispersed in anhydrous formic acid. The mass fraction of graphene oxide in the dispersion is 3%. Add 1.2 g of dried regenerated silk protein film to the above dispersion liquid, and stir for 2 h with a magnetic stirrer to obtain a uniform spinning liquid. The mass fraction of the regenerated silk protein dry film in the spinning solution is 12%. Adjust the working parameters of the electrospinning device: the voltage is 15kV, the flow rate of the spinning solution is 0.5mL / h, the distance between the spinneret and the collecting device is 18cm, the above spinning solution is added to a 5mL glass syringe, and the electrospinning is carried out for 2h A porous nanofibrous membrane with a thickness of 0.6 mm is then obtained on the collecting device.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com