Treatment method for waste LiMn1-x-yNixCoyO2 ternary battery cathode material

A technology for nickel-cobalt lithium manganese oxide and ternary batteries, which is applied in the field of processing positive electrode materials of waste nickel-cobalt lithium manganese oxide ternary batteries, can solve the problems of low recovery rate, cumbersome process, and impure products, and achieve improved recovery rate , The process is simple, and the effect of avoiding the separation of nickel, cobalt and manganese

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

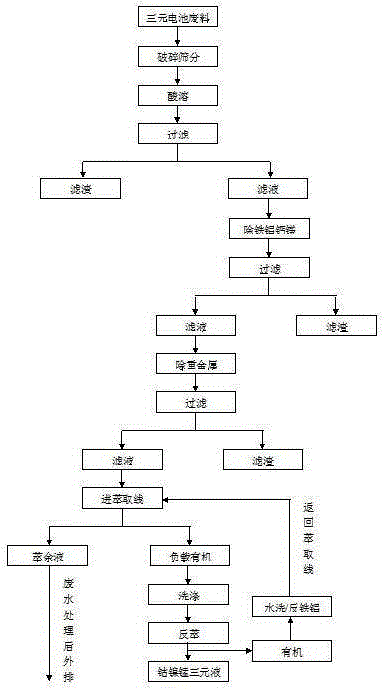

Image

Examples

Embodiment 1

[0023] A kind of processing method of waste and old nickel-cobalt lithium manganese oxide ternary battery cathode material comprises the following steps:

[0024] (1) Pretreatment, the positive electrode material of the waste nickel-cobalt-lithium manganese oxide ternary battery is crushed and passed through an 80-mesh sieve, and the under-sieve is taken;

[0025] (2) Dissolve, add the undersieve to 2mol / l acid solution according to the solid-to-liquid ratio of 1:4, add the reducing agent according to 1 times the total molar number of cobalt, nickel and manganese, stir and react at 80°C for 5 hours, and the stirring speed is 200r / min, then carry out solid-liquid separation, obtain the first filtrate and the first filter residue;

[0026] (3) Remove impurities, adjust the pH of the first filtrate to 4.5 with lye, and at the same time add oxidant according to 2 times the total molar number of ferrous iron in the first filtrate, and add fluoride according to 4 times the molar nu...

Embodiment 2

[0037] A kind of processing method of waste and old nickel-cobalt lithium manganese oxide ternary battery cathode material comprises the following steps:

[0038] (1) Pretreatment, the positive electrode material of the waste nickel-cobalt lithium manganate ternary battery is crushed and passed through a 60-mesh sieve, and the under-sieve is taken;

[0039] (2) Dissolve, add the undersieve to 3mol / l acid solution according to the solid-liquid ratio of 1:5, add the reducing agent according to twice the total molar number of cobalt, nickel and manganese, stir and react at 90°C for 5 hours, and the stirring speed is 100r / min, then carry out solid-liquid separation, obtain the first filtrate and the first filter residue;

[0040] (3) Remove impurities, adjust the first filtrate to pH 5 with lye, add oxidizing agent according to 1.5 times the total moles of ferrous iron in the first filtrate, and add fluoride according to 3 times the moles of calcium and magnesium at the same time...

Embodiment 3

[0051] A kind of processing method of waste and old nickel-cobalt lithium manganese oxide ternary battery cathode material comprises the following steps:

[0052] (1) Pretreatment, the positive electrode material of the waste nickel-cobalt lithium manganate ternary battery is crushed and passed through a 60-mesh sieve, and the under-sieve is taken;

[0053] (2) Dissolve, add the undersieve to 3mol / l acid solution according to the solid-to-liquid ratio of 1:6, add the reducing agent according to twice the total molar number of cobalt, nickel and manganese, stir and react at 90°C for 5 hours, and the stirring speed is 200r / min, then carry out solid-liquid separation, obtain the first filtrate and the first filter residue;

[0054] (3) Remove impurities, adjust the pH of the first filtrate to 5 with lye, add oxidizing agent according to 1.25 times of the total moles of ferrous iron in the first filtrate, and add fluoride according to 2.7 times of the moles of calcium and magnesi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com