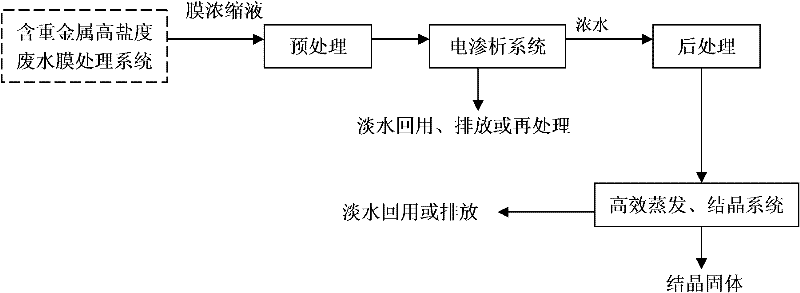

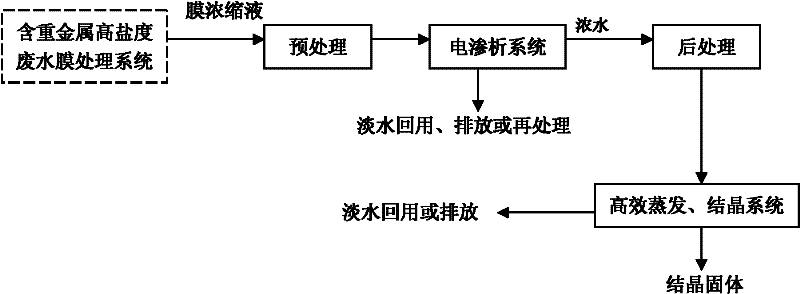

Electrodialysis-efficient evaporation method for treating mining and metallurgy waste water membrane filtrating concentrate

A technology of electrodialysis and concentrated solution, which is applied in the fields of energy waste water treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. , Wide application prospects, low environmental pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The wastewater from a lead-zinc smelter is mainly treated with lime (stone) neutralization + oxidative flocculation + electrochemical + membrane treatment, nanofiltration and reverse osmosis membrane filtration concentrate, its water quality indicators: Pb: 0.4774mg / l, Zn: 0.0402 mg / l, Cd: 0.1898 mg / l, As: 0.015 mg / l, F: 42.09 mg / l, Cl: 11316 mg / l, Na: 8759 mg / l. First adjust the pH of the concentrated solution to 9, control its temperature at 25±0.5°C, control the water flow rate at 300L / h, and enter the electrodialysis system. Under the action of a DC electric field with a voltage and current of 250V and 3A, the operating pressure is 1.0 kg / cm 2 , using a 3-stage packed bed electrodialysis system for further concentration tests, using polytetrafluoroethylene homogeneous positive and negative membranes (F46). Control parameters: turbidity: <3mg / l; oxygen consumption: <3mg / l (KMnO4); iron and manganese content: iron: <0.3mg / l, manganese: <0.1mg / l; influent sludge densi...

Embodiment 2

[0028]A copper mine contains acidic wastewater containing heavy metals. The treatment process is mainly lime (stone) neutralization + oxidation flocculation + membrane treatment. Membrane (nanofiltration + reverse osmosis) filters the concentrated solution. The water quality index: Cu: 1.31mg / l , Pb: 0.174mg / l, Zn: 0.063mg / l, Fe: 0.820mg / l, Cl: 8975mg / l, Na: 6849mg / l. After chemical redox and preheating treatment, first adjust the pH of the concentrated solution to 7.5, control its temperature at 25±0.5°C, control the water flow rate at 300L / h, and enter the electrodialysis system. Under the action of 3A DC electric field, the operating pressure is 1.0kg / cm 2 , using a single-stage inverted electrodialysis system for further concentration tests, using the slurry method perchlorethylene positive membrane (DS-SO2). Every 15 to 20 minutes of operation, the polarity of the positive and negative electrodes is reversed, which can automatically clean the dirt formed on the surface o...

Embodiment 3

[0030] Wastewater from a copper smelter, the treatment process is mainly lime neutralization + sulfide precipitation + membrane treatment, nanofiltration and reverse osmosis membrane filtration mixed concentrate, its water quality indicators: Cu: 0.284mg / l, Pb: 0.184mg / l , Zn: 0.1548mg / l, Cd: 0.0427mg / l, As: 0.028mg / l, F: 30.16mg / l, Cl: 5425mg / l, Na: 4152mg / l. After the necessary slag separation, precipitation, flocculation and precipitation treatment, first adjust the pH of the concentrated solution to 8, control its temperature at 25±0.5°C, control the water flow rate at 300L / h, and enter the electrodialysis system. Under the action of a DC electric field of 250V and 3A, the operating pressure is 1.0kg / cm 2 , using a three-stage bipolar membrane electrodialysis system for further concentration tests, using polyethylene heterogeneous ion exchange membranes. Control conditions: (1) Turbidity ≤ 0.3mg / l; (2) Oxygen consumption ≤ 2mg / l; (3) Free chlorine < 0.2mg / l; (4) Iron cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com