Technology for dealkalizing red mud

A red mud and dealkalization technology, applied in sludge treatment, process efficiency improvement, solid waste removal, etc., can solve the problems of cumbersome operation and difficult control of required conditions, and achieves the solution of large-scale stockpiling, efficient dealkalization, The effect of realizing economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

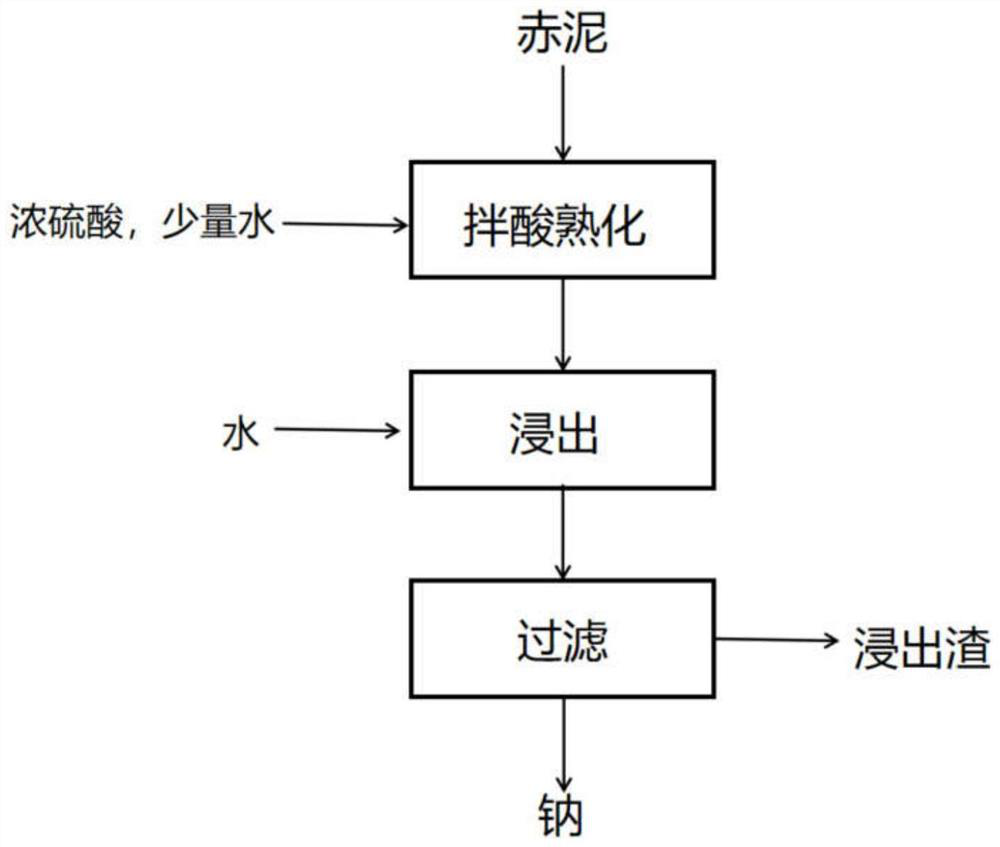

Method used

Image

Examples

Embodiment 1

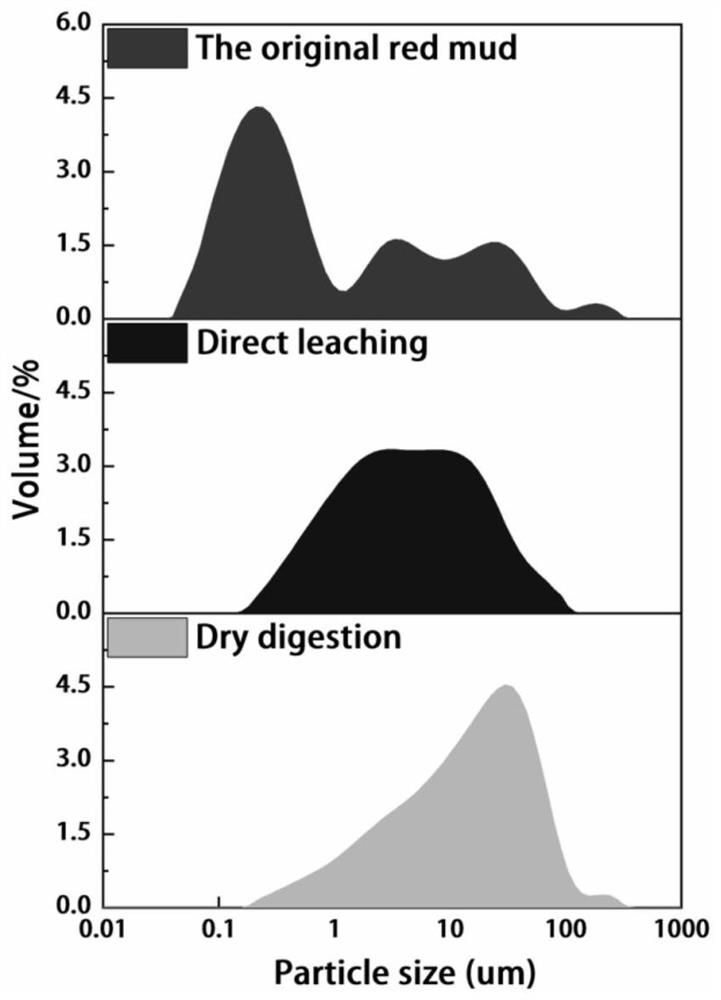

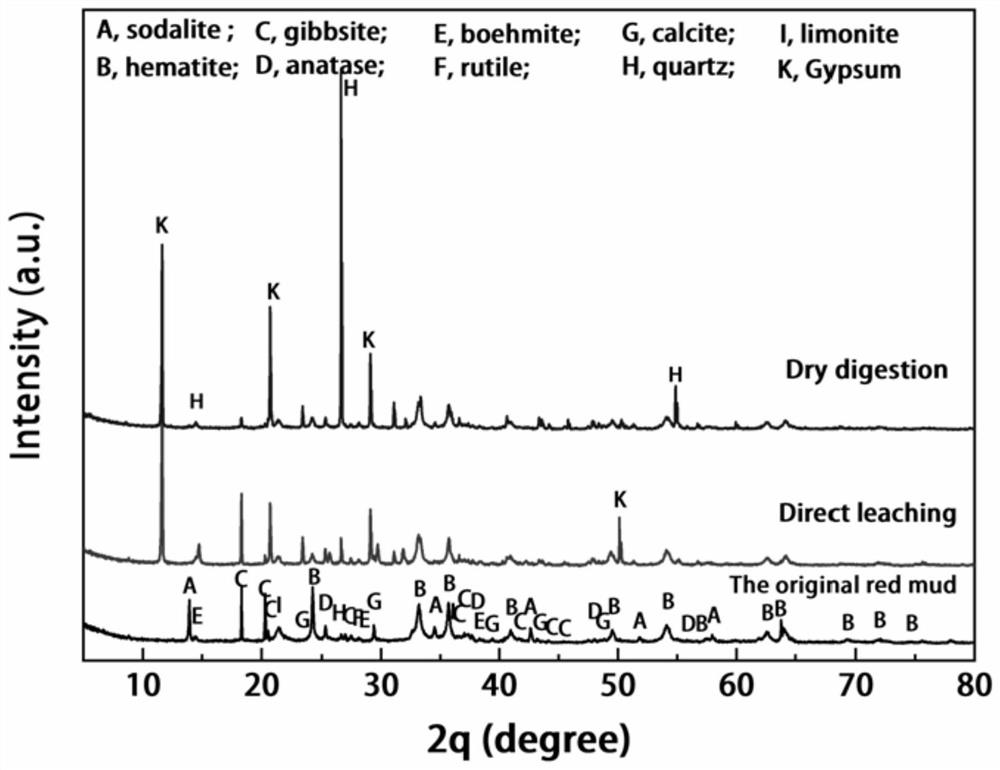

[0030] The raw material is red mud tailings from an aluminum industry in Shandong, and the mass percentage of the main component in the red mud (average particle size is 5 microns) is SiO 2 : 24.35%, CaO: 43.28%, Al 2 o 3 : 4.45%, K 2 O: 0.46%, Na 2 O: 6.75%, MgO: 0.52%, Fe 2 o 3 : 8.78%.

[0031] (1) Stir and mix red mud, concentrated sulfuric acid and water according to the weight ratio of 50:9:15 to make slurry A, and the concentrated sulfuric acid is sulfuric acid with a concentration of 98% by mass.

[0032] (2) Set the slurry A to stand at a temperature of 30 degrees Celsius for 30 minutes.

[0033] (3) Add the dehydrated water into the slurry A according to the solid-to-liquid ratio of 1:3 to obtain the mixture, continue to stir for 15 minutes, and then carry out suction filtration. The stirring speed is 300 rpm, and the temperature of the mixture is controlled at 30 degrees Celsius during stirring.

[0034] (4) Solid-liquid separation, the liquid phase is used t...

Embodiment 2

[0037] The raw material is the red mud tailings of an aluminum industry in Shandong, and the mass percentage of the main component in the red mud (average particle size is 1 micron) is SiO 2 : 25.75%, CaO: 49.65%, Al 2 o 3 : 6.56%, K 2 O: 0.75%, Na 2 O: 1.24%, MgO: 0.82%, Fe 2 o 3 : 8.79%.

[0038] (1) Stir and mix red mud, concentrated sulfuric acid and deionized water according to the weight ratio of 50:12:15 to prepare slurry A. The concentrated sulfuric acid is sulfuric acid with a concentration of 98% by mass.

[0039] (2) Set the slurry A to stand at a temperature of 40 degrees Celsius for 30 minutes.

[0040] (3) Add deionized water into the slurry A according to the solid-to-liquid ratio of 1:3 to obtain the mixture, continue to stir for 15 minutes and then carry out suction filtration, the stirring speed is 300 rpm, and the temperature of the mixture is controlled at 25 degrees Celsius during stirring.

[0041] (4) Solid-liquid separation, the liquid phase is u...

Embodiment 3

[0044] The raw material is the red mud tailings of an aluminum industry in Shandong, and the mass percentage of the main component in the red mud (average particle size is 1 micron) is SiO 2: 26.4%, CaO: 42.75%, Al 2 o 3 : 7.56%, K 2 O: 0.85%, Na 2 O: 1.32%, MgO: 0.88%, Fe 2 o 3 : 8.49%.

[0045] (1) Stir and mix red mud, concentrated sulfuric acid and deionized water according to the weight ratio of 50:3:15 to make slurry A, and the concentrated sulfuric acid is sulfuric acid with a concentration of 98% by mass.

[0046] (2) Set the slurry A to stand at a temperature of 30 degrees Celsius for 30 minutes.

[0047] (3) Add deionized water into the slurry A according to the solid-to-liquid ratio of 1:3 to obtain a mixture, continue to stir for 15 minutes and then perform suction filtration at a stirring speed of 300 rpm, and control the temperature of the mixture to 30 degrees Celsius during stirring.

[0048] (4) Solid-liquid separation, the liquid phase is used to recov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com