A method of red mud acid treatment for alkali removal

A technology of red mud acid and red mud, applied in chemical instruments and methods, cement production, halogen/halogen acid, etc., can solve the problems of difficult filtration, difficult to realize industrial production, no low-cost application, etc. Filtration performance, effect of reducing alkali content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

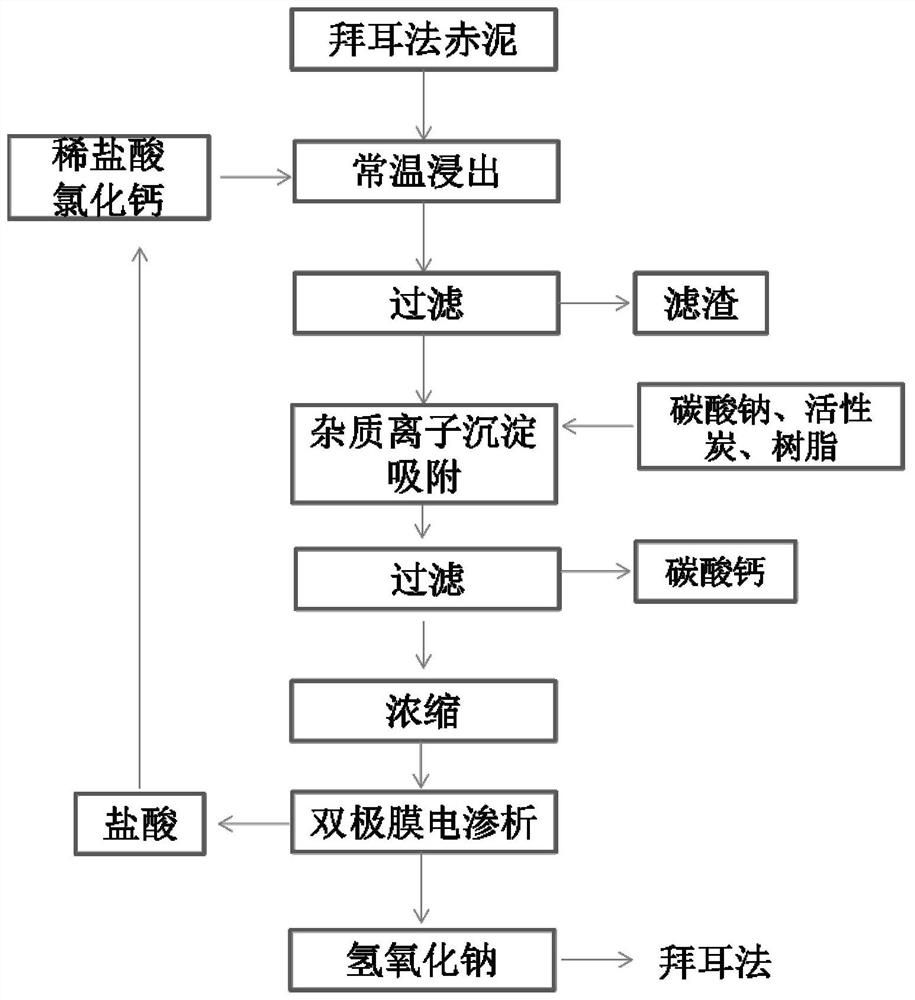

Method used

Image

Examples

Embodiment 1

[0039] The raw material is red mud tailings from an aluminum industry in Shandong, and the main content of each component is SiO 2 : 23.25%, CaO: 42.35%, Al 2 o 3 : 4.56%, K 2 O: 0.65%, Na 2 O: 1.52%, MgO: 0.92%, Fe 2 o 3 : 8.29%.

[0040] (1) Mix 1Kg of red mud with 0.5Kg of calcium chloride and 2Kg of 3% hydrochloric acid, the reaction temperature is 25°C, the pH of the leaching end point is controlled at 2.5, and leaching is performed for 30 minutes;

[0041] (2) Filtrate for 1.5 minutes to complete the separation of the leaching slag and the leaching liquid, and the obtained leaching slag is used as a raw material for producing cement.

[0042] (3) Add sodium carbonate, activated carbon and resin to the leaching solution for purification and precipitation reaction. During the purification and precipitation process, the mass ratio of sodium carbonate, activated carbon and resin to red mud is 0.03:0.05:0.01:1 respectively, and the reaction time is 20min. Stir The spee...

Embodiment 2

[0046] The raw material is red mud tailings from an aluminum industry in Shandong, the main content of each component is SiO2: 23.25%, CaO: 42.35%, Al2O3: 4.56%, K2O: 0.65%, Na2O: 1.52%, MgO: 0.92%, Fe2O3: 8.29% .

[0047] (1) Mix 1Kg of red mud with 0.6Kg of calcium chloride and 2.5Kg of 3% hydrochloric acid, the reaction temperature is 30°C, the pH of the leaching end point is controlled at 4, and the leaching is performed for 45 minutes;

[0048] (2) Filtrate for 2 minutes to complete the separation of the leaching slag and the leaching liquid, and the obtained leaching slag is used as a raw material for producing cement.

[0049] (3) Add sodium carbonate, activated carbon and resin to the leaching solution for purification and precipitation reaction. During the purification and precipitation process, the mass ratio of sodium carbonate, activated carbon and resin to red mud is 0.04:0.06:0.03:1 respectively, and the reaction time is 30min. Stir The speed is 250r / min, the re...

Embodiment 3

[0053] The raw material is red mud tailings from an aluminum industry in Shandong, the main content of each component is SiO2: 23.25%, CaO: 42.35%, Al2O3: 4.56%, K2O: 0.65%, Na2O: 1.52%, MgO: 0.92%, Fe2O3: 8.29% .

[0054] (1) Mix 1Kg red mud with 0.8Kg calcium chloride and 3Kg 3% hydrochloric acid, the reaction temperature is 35°C, the pH of the leaching end point is controlled at 4, and the leaching is 50 minutes;

[0055] (2) Filtrate for 2.5 minutes to complete the separation of the leaching slag and the leaching liquid, and the obtained leaching slag is used as a raw material for producing cement.

[0056] (3) Add sodium carbonate, activated carbon and resin to the leaching solution for purification and precipitation reaction. During the purification and precipitation process, the mass ratio of sodium carbonate, activated carbon and resin to red mud is 0.05:0.06:0.02:1 respectively, and the reaction time is 25min. Stir The speed is 250r / min, the reaction temperature is 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com