A production process for obtaining sulfur concentrate from copper tailings

A production process and technology of sulfur concentrate, which is applied in the field of production process for obtaining sulfur concentrate, can solve the problems of low sulfur concentrate grade in sulfur recovery rate, large overflow loss, insufficient flotation acidity, etc. The effect of increasing the efficiency, improving sulfur production, sulfur recovery rate and improving the grade of sulfur concentrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

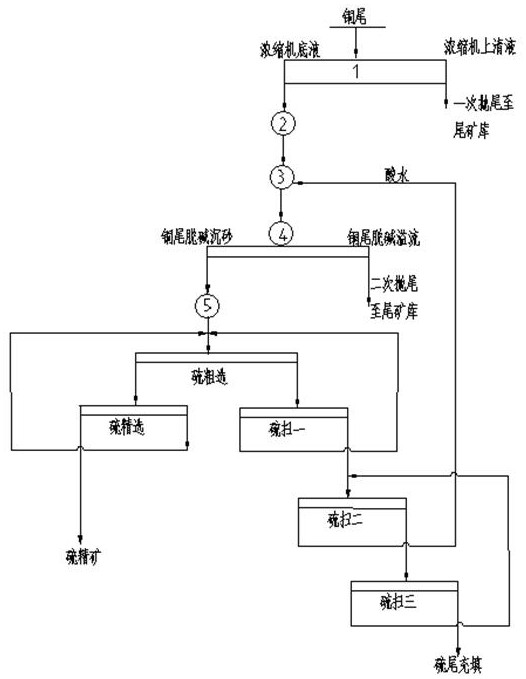

[0026] like figure 1 As shown, the present embodiment provides a production process for obtaining sulfur concentrate from copper tailings, comprising the following process steps:

[0027] S1. The copper tailings enter the drive-type thickener and are squeezed densely with a rake. The thickened ore slurry enters the ore drawing pond to form the bottom liquid of the thickener, and the supernatant liquid of the thickener is discharged with the overflow port as a tailing to the tailings pond. ;

[0028] S2. The bottom liquid of the concentrator enters the rubber lining pump, and the rubber lining pump transports the bottom liquid of the concentrator to the copper tail dealkalization slurry pump, and the slurry pump continues to lift it to the copper tail dealkalization cyclone group Carry out grading, the graded sand enters the copper tail dealkalization mixing tank to the sulfur selection process, and the dealkalization overflow is discharged with the overflow port as secondary ...

Embodiment 2

[0036] This embodiment provides a production process for obtaining sulfur concentrate from copper tailings. On the basis of Embodiment 1, the step S3 further includes: after the sulfur sweep No. 2 middle ore is introduced into the pump tank, adding acid through the pump tank Water and clean water are mixed and slurried, and the graded sand is added to the mixing tank to add acid water to re-slurp to achieve the third sulfur activation. Such a new process greatly improves the sulfur output of the selected copper tails and achieves the purpose of rapidly activating the primary sulfur in the copper tails.

Embodiment 3

[0038] This example provides a production process for obtaining sulfur concentrate from copper tailings. On the basis of Example 1, the PH of the minerals after slurring in the pump tank is 7.5, and the slurries in the mixing tank are PH 7.5. The pH is 7.2 and keep stirring for 1-2h, then continue to mix with acid water to make the pH 7 and keep stirring for 0.5-1h, then continue to adjust the pH to 6.5 and keep stirring for 30-45min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com