Method and system for comprehensive utilization of red mud

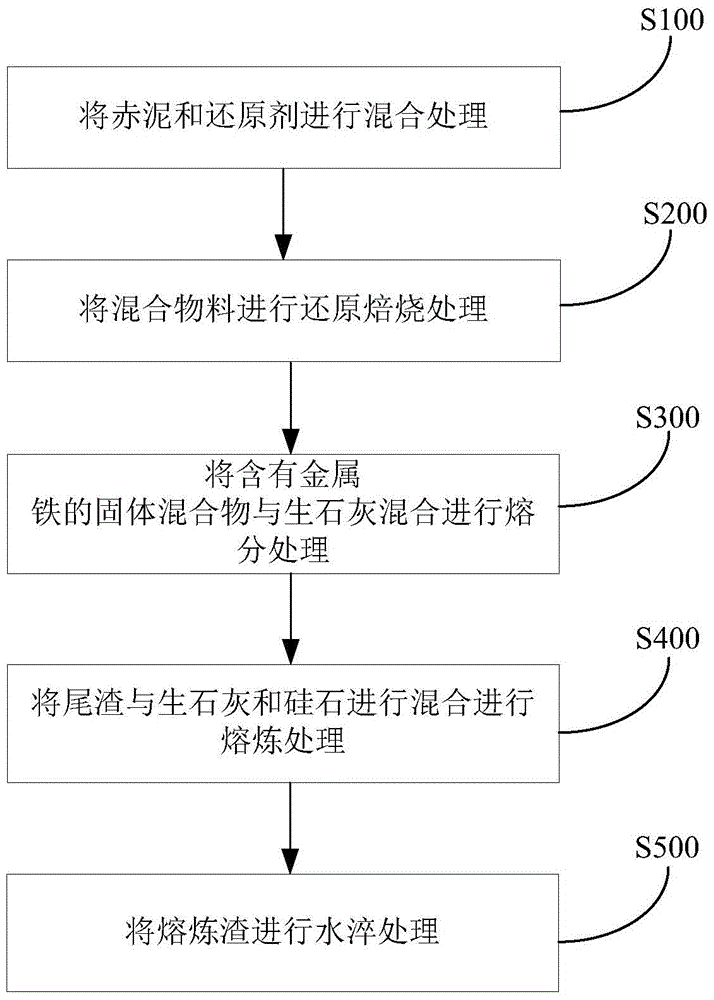

A technology of red mud and mixture, applied in the field of comprehensive utilization of red mud, can solve the problem of low utilization rate of industrial waste, and achieve the effects of solving low utilization rate of industrial waste, efficient dealkalization, and long-term storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

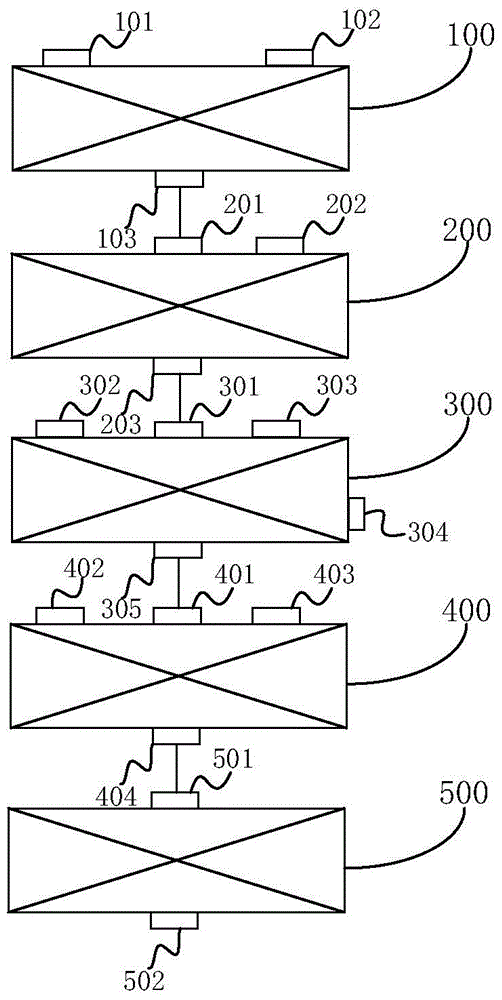

Method used

Image

Examples

Embodiment 1

[0065] Red mud and reduced coal are mixed and batched to obtain a mixed material, and then the mixed material is reduced and roasted at 1300°C to obtain a solid mixture containing sodium oxide and metallic iron, wherein the sodium content of the solid mixture containing metallic iron is 3.68 wt%, the removal rate of sodium is 45wt%, and then the obtained solid mixture containing metallic iron is mixed with quicklime and then subjected to melting treatment, wherein the mass ratio of solid mixture containing metallic iron to quicklime is 100:5 to obtain sodium oxide, Molten iron and tailings, wherein, the comprehensive dealkalization rate reaches 92wt% during the reduction roasting treatment and melting process, the iron content in the hot metal is 96wt%, and the iron recovery rate is 97wt%, and then the tailings are mixed with quicklime and silica according to the mass ratio of 100 : 25: 35 are mixed and smelted to obtain smelting slag, and then the obtained smelting slag is sub...

Embodiment 2

[0067] Red mud and reduced coal are mixed and batched to obtain a mixed material, and then the mixed material is reduced and roasted at 1280°C to obtain a solid mixture containing sodium oxide and metallic iron, wherein the sodium content of the solid mixture containing metallic iron is 4.18 wt%, the removal rate of sodium is 40wt%, and then the obtained solid mixture containing metallic iron is mixed with quicklime and then subjected to melting treatment, wherein the mass ratio of solid mixture containing metallic iron to quicklime is 100:5 to obtain sodium oxide, Molten iron and tailings, wherein, the comprehensive dealkalization rate reaches 92wt% in reduction roasting treatment and melting process, the iron content in hot metal is 95wt%, and the iron recovery rate is 98wt%, and then the tailings are mixed with quicklime and silica according to the mass ratio of 100 : 28: 35 are mixed and smelted to obtain smelting slag, and then the obtained smelting slag is subjected to wa...

Embodiment 3

[0069] Red mud and reduced coal are mixed and batched to obtain a mixed material, and then the mixed material is reduced and roasted at 1280°C to obtain a solid mixture containing sodium oxide and metallic iron, wherein the sodium content of the solid mixture containing metallic iron is 3.29 wt%, the removal rate of sodium is 45wt%, and then the obtained solid mixture containing metallic iron is mixed with quicklime to carry out melting treatment, wherein, the mass ratio of solid mixture containing metallic iron to quicklime is 100:8 to obtain sodium oxide, Molten iron and tailings, wherein, the comprehensive dealkalization rate reaches 92wt% during reduction roasting treatment and melting process, the iron content in hot metal is 96wt%, and the iron recovery rate is 96wt%, and then the tailings are mixed with quicklime and silica according to the mass ratio of 100 : 30: 32 mixed and smelted to obtain smelted slag, and then water quenched to obtain smelted slag to obtain water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com