A kind of Bayer process red mud acid treatment method for removing alkali and recovering sodium

A Bayer red mud and acid treatment technology, applied in chemical instruments and methods, cement production, alkali metal compounds, etc., can solve the problems of high cost of red mud desodiumization, limited degree of red mud desodiumization, difficult filtration, etc., to achieve Improved filtration performance, low cost, and reduced recycling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

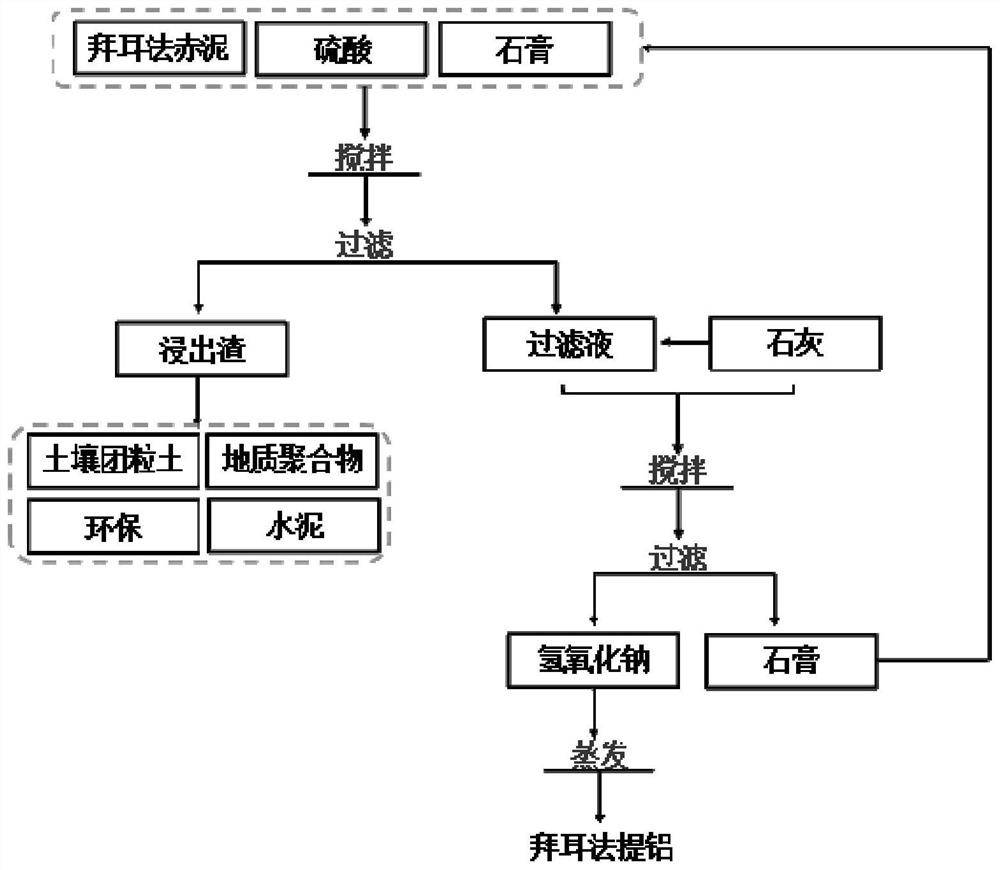

Method used

Image

Examples

Embodiment 1

[0040] The raw material is red mud tailings from an aluminum industry in Shandong, and the main content of each component is SiO 2 : 22.34%, CaO: 44.32%, Al 2 o 3 : 4.23%, K 2 O: 0.33%, Na 2 O: 7.25%, MgO: 0.52%, Fe 2 o 3 : 8.33%.

[0041] (1) Mix 1Kg of red mud with 0.5Kg of desulfurized gypsum and 0.05Kg of concentrated sulfuric acid (98%), add water to obtain a mixed slurry, control the liquid-solid ratio of the mixed slurry to 2:1, and control the temperature to 28°C. Stirring and leaching for 0.5h; control the pH of the leaching end point to 4.5,

[0042] (2) Filtrate for 2 minutes to complete the separation of the leaching slag and the leachate, and use the leaching slag as a raw material for soil aggregates or building materials;

[0043](3) Lime (0.04kg) was added to the leaching solution, reacted at 35°C for 40 minutes, separated from solid and liquid, and the obtained filter residue was calcium sulfate, which was returned to (1) as the leaching raw material fo...

Embodiment 2

[0046] The raw material is red mud tailings from an aluminum industry in Shandong, and the main content of each component is SiO 2 : 22.78%, CaO: 35.43%, Al 2 o 3 : 4.26%, K 2 O: 0.35%, Na 2 O: 7.52%, MgO: 0.67%, Fe 2 o 3 : 7.56%.

[0047] (1) Mix 1Kg red mud with 0.6Kg phosphogypsum and 0.07Kg concentrated sulfuric acid (98%), add water to obtain a mixed slurry, control the liquid-solid ratio of the mixed slurry to 3:1, and control the temperature to 30°C. Stirring and leaching in medium temperature for 40min; control the pH of the leaching end point to be 5,

[0048] (2) Filtrate for 1 min to complete the separation of the leaching slag and the leachate, and use the leaching slag as a raw material for soil aggregates or building materials;

[0049] (3) Lime (0.05kg) was added to the leaching solution, reacted at 45°C for 30 minutes, separated from solid and liquid, and obtained filter residue was calcium sulfate, which was returned to (1) as the leaching raw material ...

Embodiment 3

[0052] The raw material is red mud tailings from an aluminum industry in Shandong, and the main content of each component is SiO 2 : 23.25%, CaO: 42.35%, Al 2 o 3 : 4.56%, K 2 O: 0.65%, Na 2 O: 1.52%, MgO: 0.92%, Fe 2 o 3 : 8.29%.

[0053] (1) Mix 1Kg red mud with 0.5Kg calcium sulfate and 0.1Kg concentrated sulfuric acid (98%), add water to obtain a mixed slurry, control the liquid-solid ratio of the mixed slurry to 5:1, and control the temperature to 25°C. Stirring and leaching in medium temperature for 30min, controlling the pH of the leaching end point to be 6, the calcium sulfate used is the calcium sulfate precipitate obtained in step (3) in Example 2.

[0054] (2) Filtrate for 0.5min to complete the separation of the leaching slag and the leachate, and the leaching slag is used as the raw material for soil aggregates or building materials;

[0055] (3) Add lime (0.1kg) to the leaching solution, react at 50°C for 30 minutes, separate solid and liquid, obtain the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com