Anti-clogging heat accumulating type burner and industrial furnace

A regenerative, burner technology, applied in burners, gas fuel burners, combustion methods, etc., can solve the problems of waste of resources, high energy consumption and cost, pollute the environment, etc., achieve effective recovery and prevent clogging of burners Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

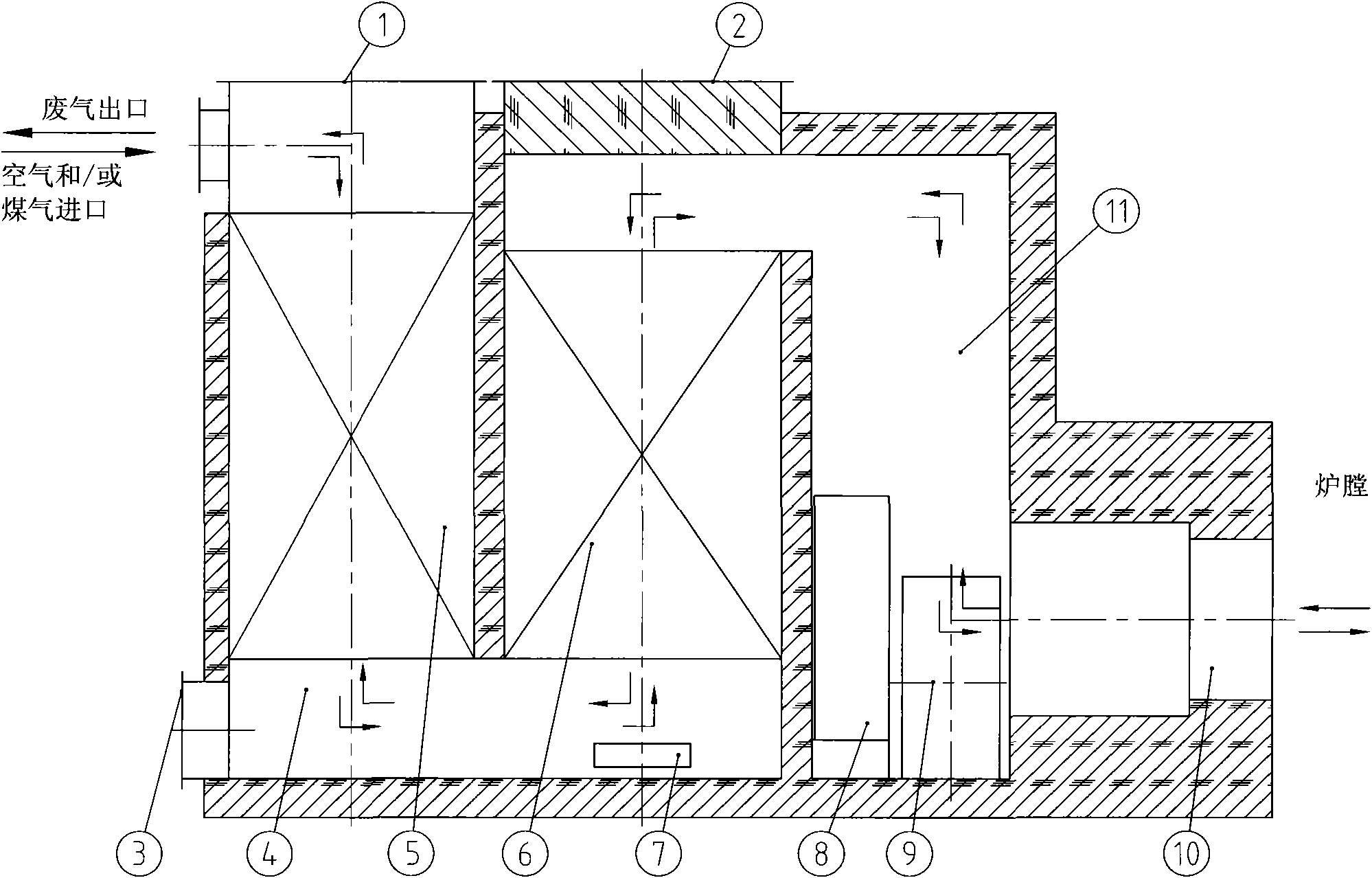

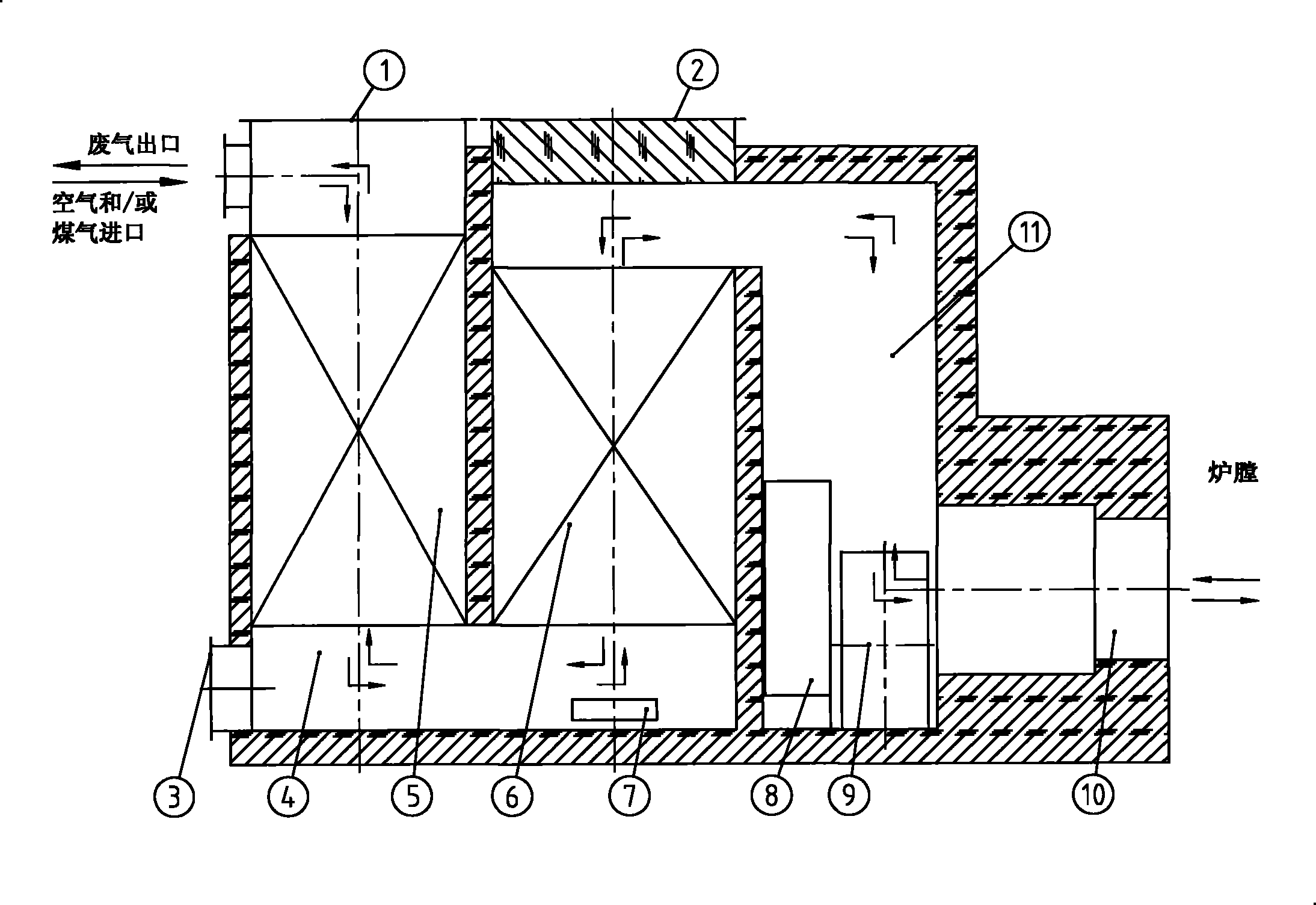

[0015] The regenerative burner of the present invention, its preferred embodiment is as follows figure 1 As shown, it includes a shell, the upper part of one side of the shell is provided with a combustion air inlet and / or a gas inlet, and the lower part of the other side is provided with a high-temperature gas nozzle.

[0016] The housing is equipped with a low-temperature regenerator and a high-temperature regenerator. The low-temperature regenerator and the high-temperature regenerator are respectively arranged in independent cavities, and the inspection port of the low-temperature regenerator and the high-temperature regenerator are respectively arranged above the cavity. The maintenance port and the heat storage body are easy to replace.

[0017] A dust settling chamber is arranged under the low temperature regenerator and the high temperature regenerator, and a dust recovery hole and a cooling air outlet are arranged on one side of the dust settling chamber.

[0018] A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com