Ionic liquid for assisting oil-sand separation and separation method

An ionic liquid and auxiliary oil technology, which is used in the petroleum industry, the preparation of liquid hydrocarbon mixtures, and organic chemistry, etc., can solve the problems of not considering the degree of separation, large pollution of organic solvents, and large loss of reagents, and achieves low viscosity and environmental pollution. The effect of small, water-saving reagent losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

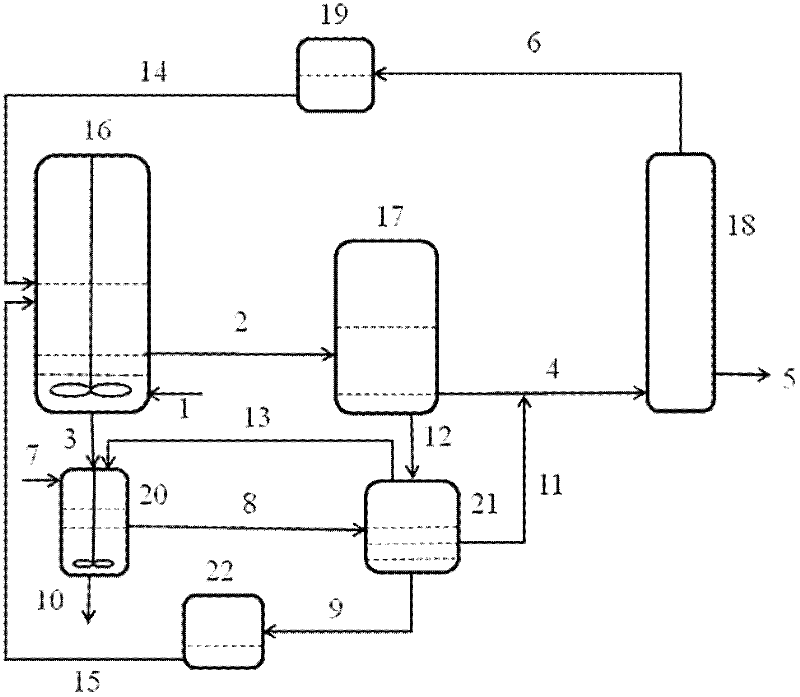

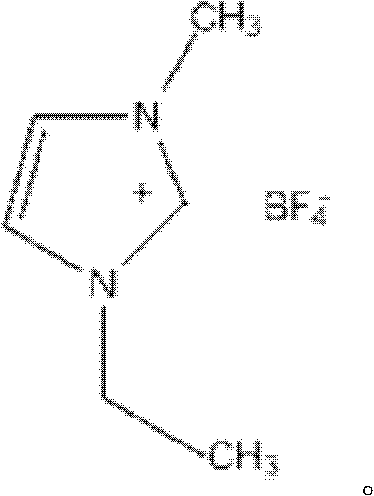

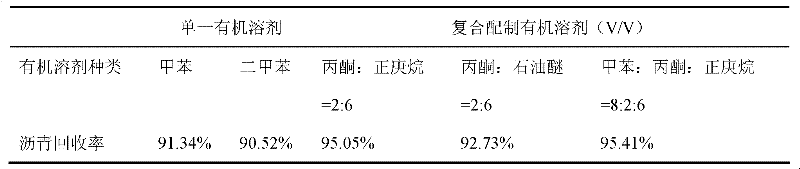

[0034] Ionic liquid-assisted oil sands extraction methods with several organic solvents.

[0035] Adopted six kinds of organic solvents to extract respectively, single organic solvent adopts toluene and xylene solution; Compound organic solvent adopts acetone and n-heptane volume ratio to be 2: 6, acetone and sherwood oil volume ratio are 2: 6, toluene: acetone: A solution with a volume ratio of n-heptane of 8:2:6.

[0036] 2kg of Canadian oil sands, 80L of organic solvent, and 2kg of ionic liquid were respectively supplied to the contact extraction tank through the feed port, the mechanical stirrer was turned on, the speed was controlled at 300rpm, and the extraction was carried out at 30°C for 2h. Close the agitator, and let the mixture stand in the contact extraction tank for 30 minutes. After the oil sand settles, open the discharge port and control the flow rate at 200L h -1 Left and right, the first layer of organic mixture phase slowly flows into the separation tank, ...

Embodiment 2

[0040] Auxiliary oil sands extraction method with several ionic liquid dosages.

[0041] The organic solvent is acetone: n-heptane = 2:6 (V / V) compound solvent, and four kinds of ionic liquids are used to extract the oil sands.

[0042] 2kg of Canadian oil sands, 80L of organic solvent, 1kg, 2kg, 3kg, and 4kg of ionic liquid were supplied to the contact extraction tank through the feed port, the mechanical stirrer was turned on, the speed was controlled at 300rpm, and the extraction was carried out at 30°C for 2h. Close the agitator, and let the mixture stand in the contact extraction tank for 30 minutes. After the oil sand settles, open the discharge port and control the flow rate at 200L h -1 Left and right, the first layer of organic mixture phase slowly flows into the separation tank, and the organic mixture and the residual ionic liquid are allowed to stand and separate in the separation tank for 10 minutes. Open the upper discharge port of the separation tank, and the ...

Embodiment 3

[0046] Ionic liquid-assisted oil sands extraction method with several organic solvent dosages.

[0047] As the organic solvent, acetone: n-heptane = 2:6 (V / V) compound solvent was used, and four kinds of organic solvents were used to extract the oil sands.

[0048] Canadian oil sands 2kg, organic solvent volumes 20L, 40L, 60L, 80L, ionic liquid dosage 2kg, supplied to the contact extraction tank through the feed port, turn on the mechanical stirrer, control the speed of 300rpm, stir and extract at 30°C for 2h. Close the agitator, and let the mixture stand in the contact extraction tank for 30 minutes. After the oil sand settles, open the discharge port and control the flow rate at 200L h -1 Left and right, the first layer of organic mixture phase slowly flows into the separation tank, and the organic mixture and the residual ionic liquid are allowed to stand and separate in the separation tank for 10 minutes. Open the upper discharge port of the separation tank, and the orga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com