Liquid container, liquid delivering device equipped therewith and liquid delivering method

A liquid container and container body technology, which is applied to liquid distribution, transportation or transfer devices, containers, rigid containers, etc. It can solve the complicated installation or replacement of liquid containers, the increase in the number of parts of the liquid delivery device, and the difficulty of liquid discharge, etc. problems, achieve the effect of saving storage space, preventing deformation, and reducing liquid residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

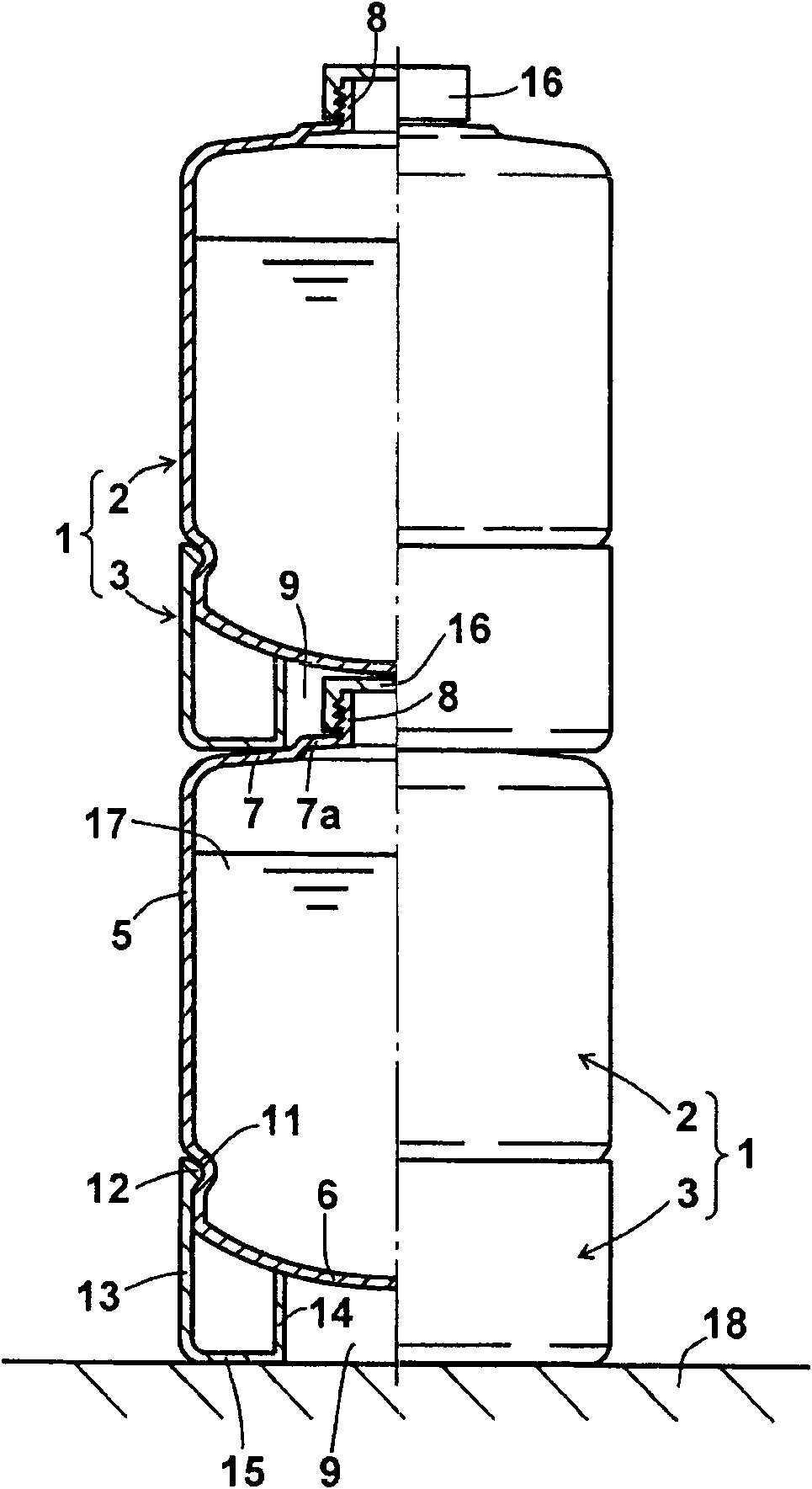

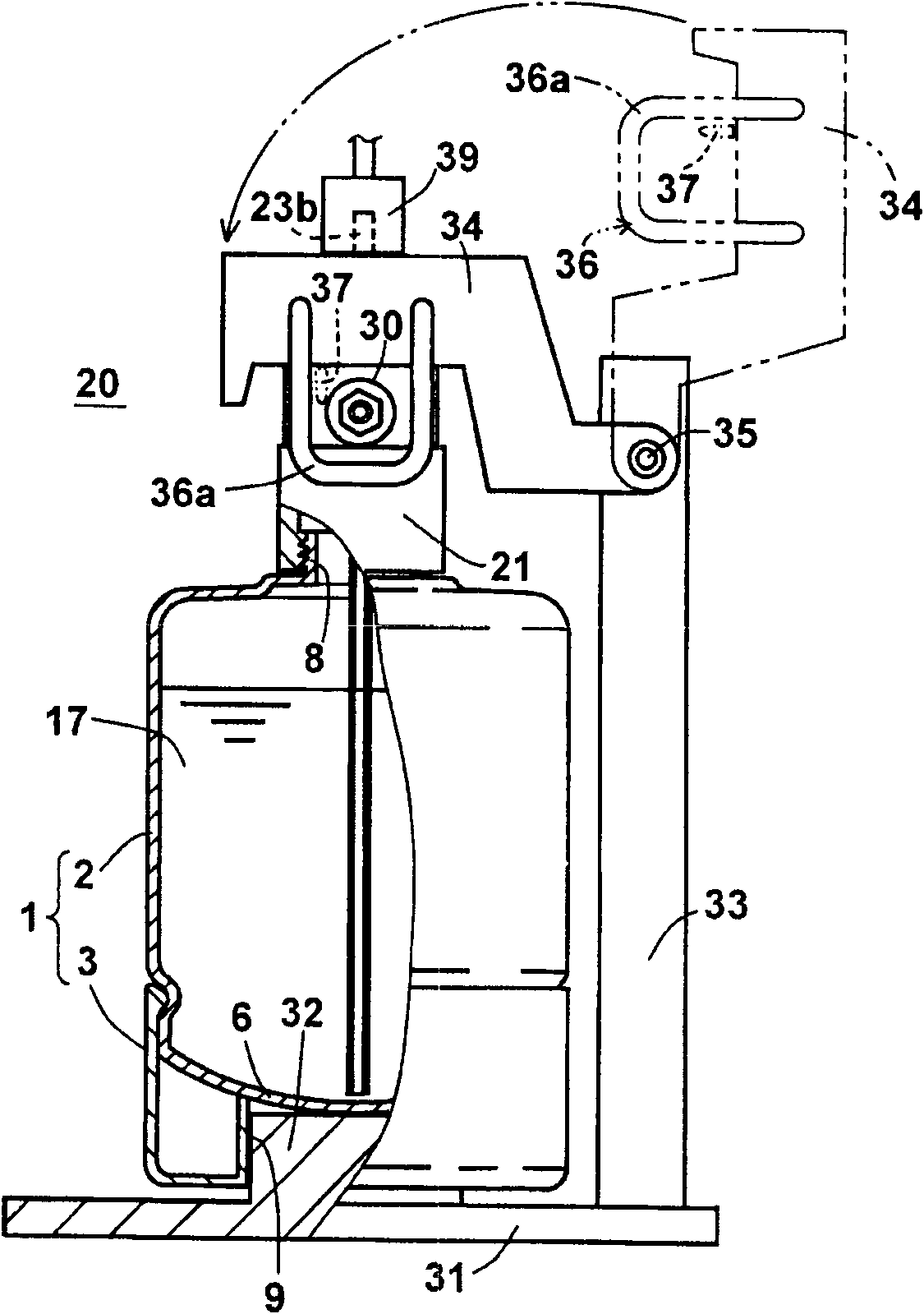

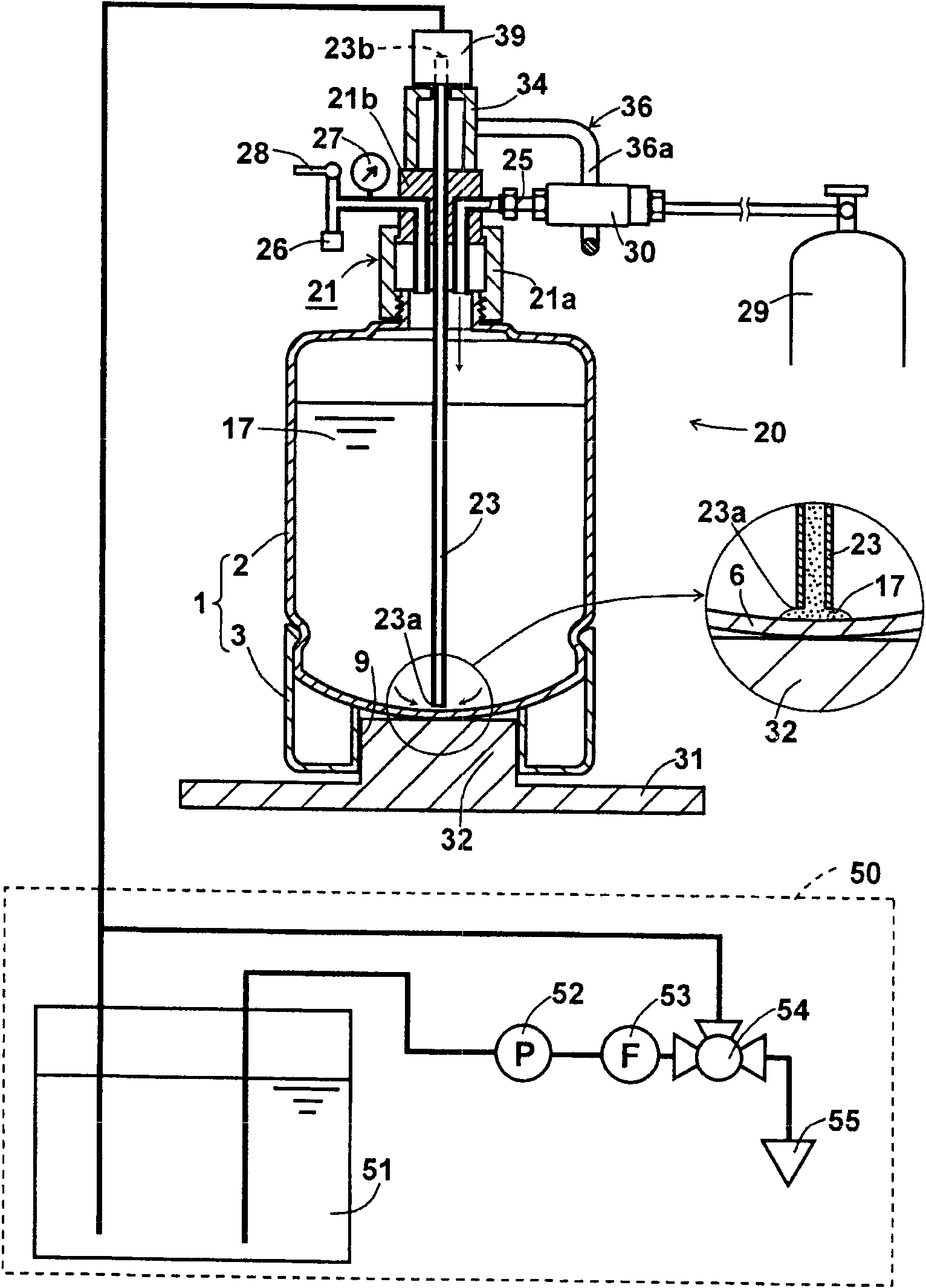

[0162] The liquid container 1 and the liquid delivery device 20 to which the present invention was applied were trial-manufactured. The container main body 2 is made of a high-density polyethylene resin with a flexural modulus of 920MPa (the density is 0.955g / cm 3 , melt index is 0.15g / 10 minutes) to form, support table 3 is to be made of linear low-density polyethylene resin (density is 0.938g / cm 3 , melt index of 3.8 g / 10 minutes) to form a 20 L container. The average plate thickness of the container main body 2 was 3 mm, and the plate thickness of the support stand 3 was 3 mm. The radius of the trunk portion 5 of the container main body 2 is 150 mm, the length of the trunk portion 5 is 300 mm, and the round bottom 6 is formed by a curved surface with a radius of 2253 mm. A liquid-feeding tube 23 with an outer diameter of 6 mm was fixed to the liquid-feeding adapter 21 so that the distance between the round bottom 6 and the end 23 a of the liquid-feeding tube 23 was 5 mm. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com