Production method for natural benzaldehyde

A production method and technology of benzaldehyde, applied in chemical instruments and methods, preparation of organic compounds, separation/purification of carbonyl compounds, etc., can solve the problems of low production efficiency and high energy consumption, and achieve increased production rate and production efficiency , the effect of energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment one: adopt method of the present invention to produce natural benzaldehyde

[0020] 1000 kilograms of concentration are 2.5% sodium carbonate aqueous solution to join in reactor 1, be heated to boiling, pass through high-pressure feed pump 3 and feed pipe 4 from header tank 2 then, according to the drip rate of 30 kilograms per hour, continue to The cinnamaldehyde raw material was added into the reaction kettle 1, and the reaction was continued for 20 hours at a temperature of 100° C. to 106° C.

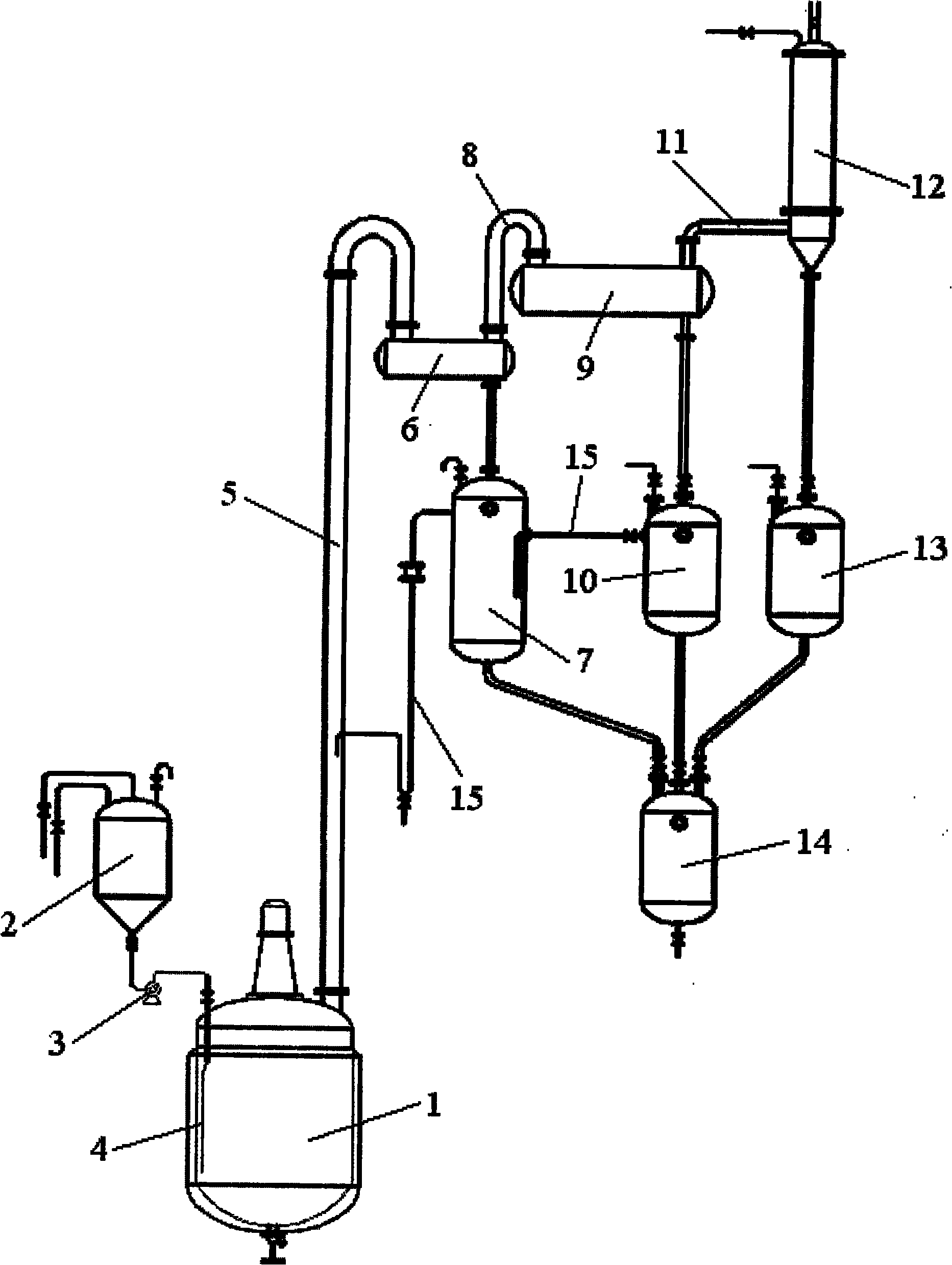

[0021] The steam containing the natural benzaldehyde product generated by the reaction enters the first-stage condenser 6 through the first-stage steam riser 5 for cooling, and the temperature of the first-stage condenser 6 is controlled within the range of 65°C to 85°C, approximately 70% of the steam is cooled in the first stage condenser 6. The oil-water mixture obtained after cooling flows into the first-stage oil-water separator 7 for layer separation, and the ...

Embodiment 2

[0025] Embodiment two: adopt existing technology to produce natural benzaldehyde

[0026] 1000 kilograms of concentration of 2.5% sodium carbonate aqueous solution is added to the reactor 21, heated to boiling, then 600 kilograms of cinnamaldehyde is added to the reactor 21 from the head tank 22 through the feed pipe 23, and heated at 100 ° C to 106 °C for 20 hours.

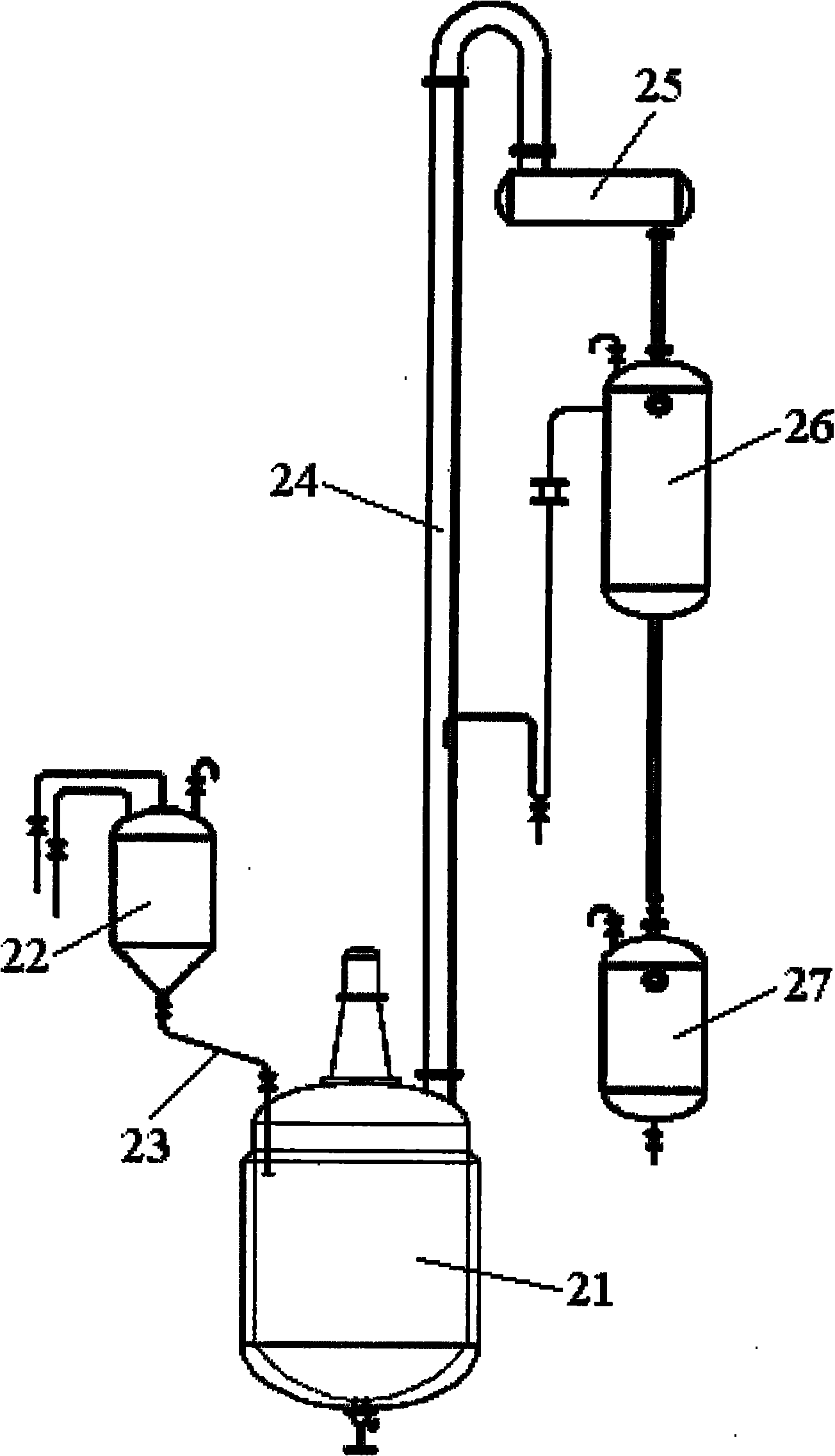

[0027] The steam generated by the reaction and containing the natural benzaldehyde product enters the condenser 25 through the steam riser 24 for cooling, and the temperature of the condenser 25 is controlled within the range of 40°C to 50°C. The oil-water mixture obtained after cooling flows into the oil-water separator 26 for layer separation, and the separated lower oil layer product flows into the product receiver 27 for collection, while the upper water layer flows back to the reactor 21 through the return pipe 28 for reuse.

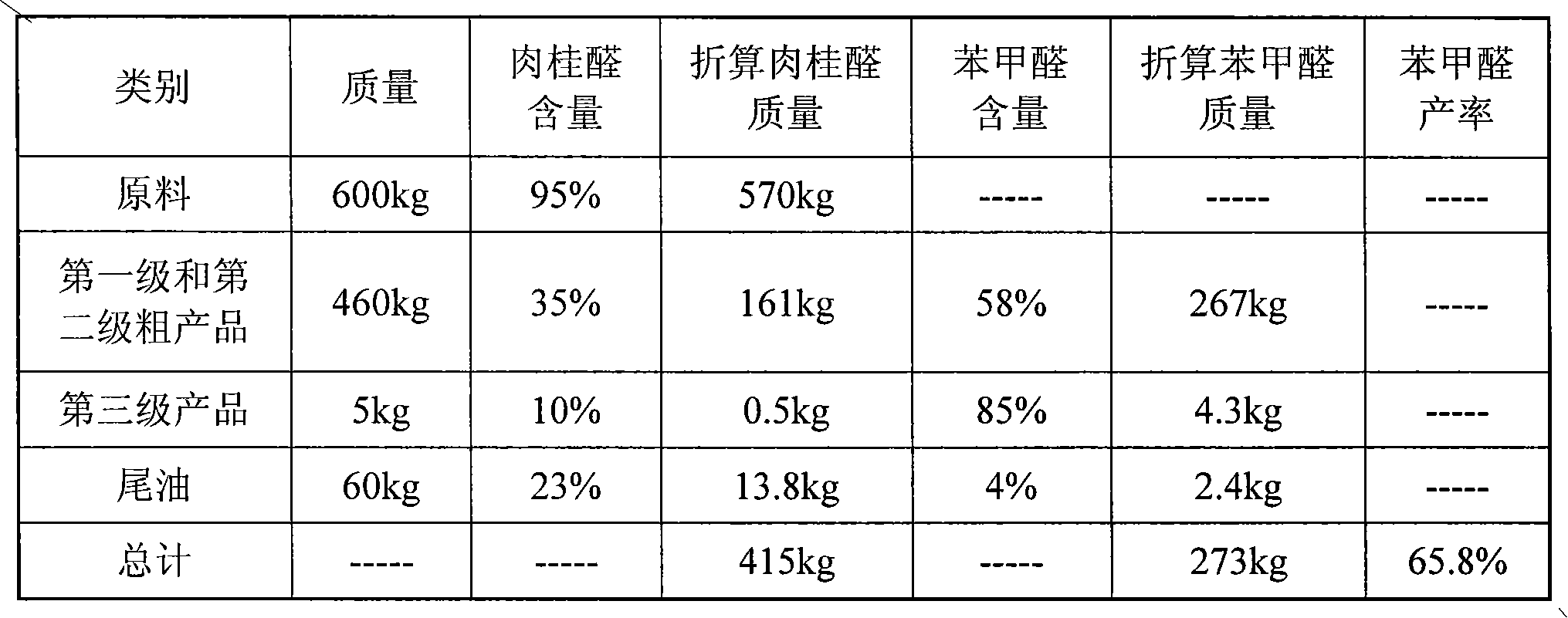

[0028] After the reaction, after detection, the natural benzaldehyde crude produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com