Method and apparatus for purifying vitamin A intermediate mynistic aldehyde

A purification method and tetradecaldehyde technology are applied in the field of purification of vitamin A intermediate tetradecaldehyde, which can solve the problem that tetradecaldehyde and β-ionone cannot be completely separated, the purity of tetradecaldehyde is not high, and the refining yield is not high. problems, to achieve the effect of short heating time, reducing decomposition side reactions, and improving product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

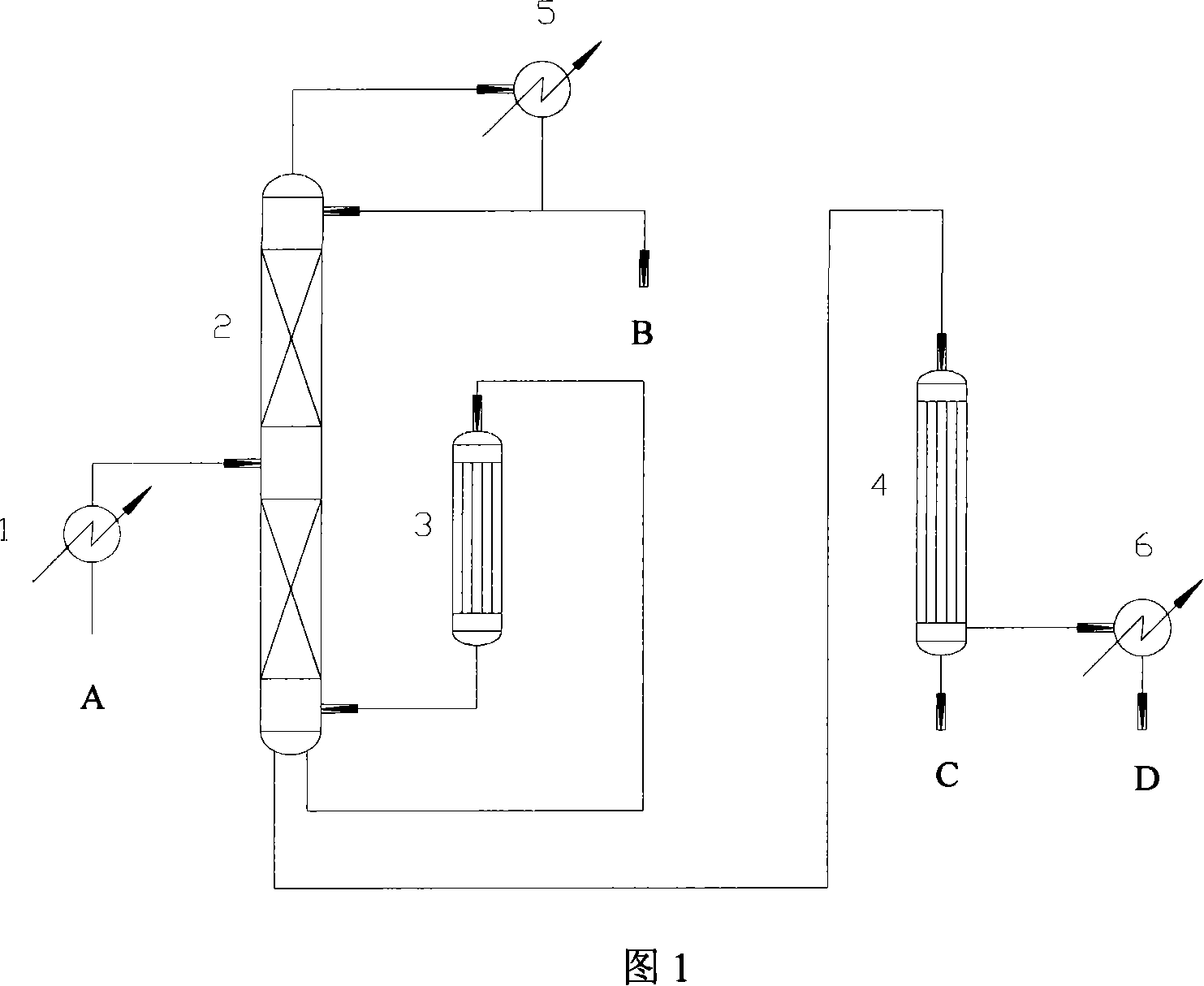

[0021] As shown in Figure 1, the purifying device of vitamin A intermediate tetradecaldehyde of the present invention is provided with heater 1, rectifying column 2, falling film reboiler 3, falling film evaporator 4, the first condenser 5 and the second condenser 6. Thick tetradecaldehyde A enters from the inlet of heater 1, and the thick tetradecaldehyde outlet of heater 1 connects the inlet of rectifying tower 2, and the top steam outlet of rectifying tower 2 connects the steam inlet of first condenser 5, and the first One of the condensed liquid outlets of the condenser 5 is connected to the upper reflux liquid inlet of the rectification column 2, and the other one flows out of the low boiler B of β-ionone. The bottom kettle material outlet of the rectification tower 2 is respectively connected to the top kettle material inlet of the falling film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com