Method for separating acetone-butanol-alcohol fermenting liquid by utilizing pervaporation-rectification coupling

A technology of pervaporation and acetone butanol, which is applied in the field of preparation of anhydrous acetone, butanol and ethanol, can solve the problems of low concentration of the first-stage pervaporation concentrated solution, increase equipment cost, and high energy consumption of operation, and achieve strong production capacity, Effects of reduced concentration cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

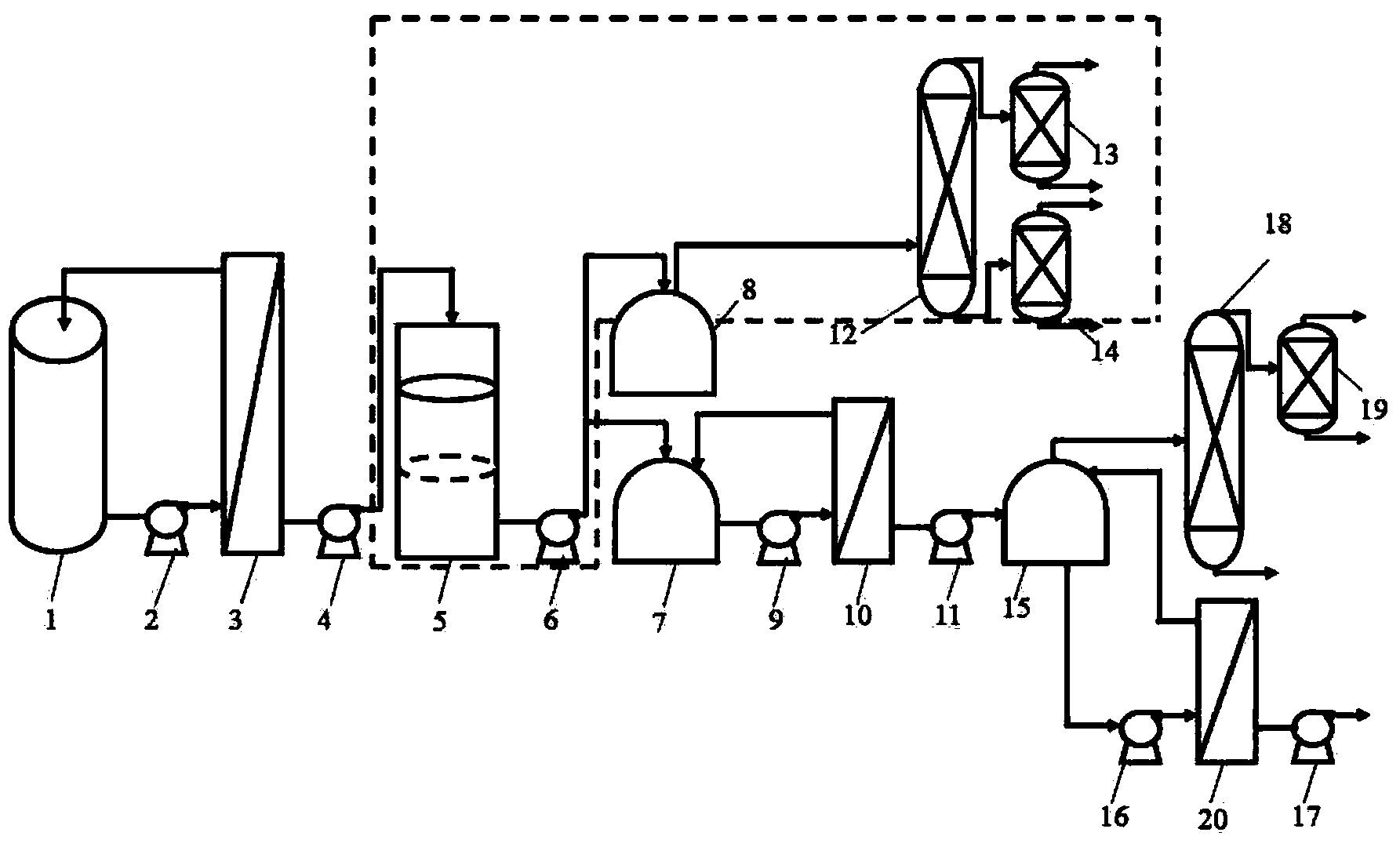

[0018]Biomass is fermented with acetone and butanol at 30°C. When the concentration of acetone, butanol and ethanol produced in the fermenter (1) reaches 1.6wt%, start the first infusion pump (2) to send the fermentation broth into the first stage In the membrane module (3), the alcohol-preferential membrane (polydimethylsiloxane / silica zeolite / polyacrylonitrile composite membrane) is used, at a temperature of 30°C, a flow rate of 0.5m / s, and a vacuum degree on the downstream side of Separation is carried out under the condition of 200Pa, and the retentate with reduced concentration is circulated to the fermenter (1) to continue fermentation. The permeate is condensed at the outlet of the first vacuum pump (4) and then sent to the liquid separation tank (5) for two-phase separation. The second infusion pump (6) is used to separate the water phase with a concentration of 21.2wt% and the concentration of 65.7wt% The % organic phase is sent into the aqueous phase storage tank (7)...

Embodiment 2

[0020] Biomass is fermented with acetone and butanol at 40°C. When the concentration of acetone, butanol and ethanol produced in the fermenter (1) reaches 0.8wt%, start the first infusion pump (2) to send the fermentation broth into the first stage In the membrane module (3), a preferential alcohol permeable membrane (polydimethylsiloxane / alumina composite membrane, alumina pore size 200nm) is used, at a temperature of 40°C, a flow rate of 2.5m / s, and a vacuum degree on the downstream side of Separation is carried out under the condition of 10000Pa, and the retentate with reduced concentration is circulated to the fermenter (1) to continue fermentation. The permeate is condensed at the outlet of the first vacuum pump (4) and sent to the liquid separation tank (5) for two-phase separation. The second infusion pump (6) is used to separate the water phase with a concentration of 27.3wt% and the concentration of 58.7wt% The % organic phase is sent into the aqueous phase storage ta...

Embodiment 3

[0022] Biomass is fermented with acetone and butanol at 40°C. When the concentration of acetone, butanol and ethanol produced in the fermenter (1) reaches 0.5wt%, start the first infusion pump (2) to send the fermentation broth into the first stage In the membrane module (3), the alcohol-preferential membrane (polydimethylsiloxane / SiO 2 hybrid membrane), the separation is carried out at a temperature of 40°C, a flow rate of 1.0m / s, and a downstream space of 500Pa, and the retentate with reduced concentration is circulated to the fermenter (1) to continue fermentation. The permeated liquid is condensed at the outlet of the first vacuum pump (4) and sent to the liquid separator tank (5), if the two-phase separation does not occur. Then, the concentration of the mixture in the liquid separation tank (5) is 18wt%, and the second infusion pump (6) is used to send the mixture into the water phase storage tank (7), and then the mixture is sent to the secondary membrane by the third i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com