Method for purifying acetone

A purification method and acetone technology, which are applied in the separation/purification of carbonyl compounds, organic chemistry, etc., can solve the problems of complicated operation steps, low acetone purity, high energy consumption, etc., and achieve a safe and simple purification process, stable product quality, and purity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

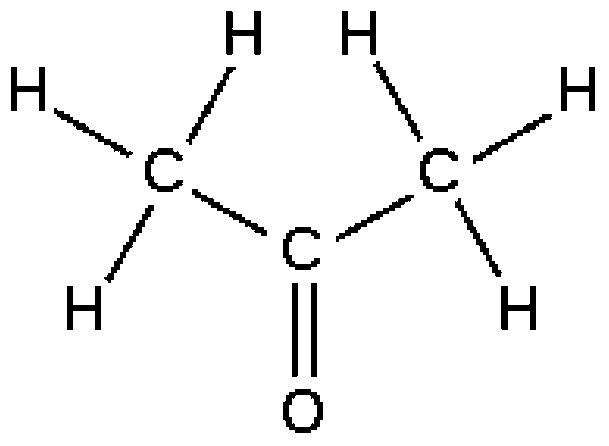

Image

Examples

Embodiment 1

[0018] Add 25ml of 0.5mol / L silver nitrate solution and 5ml of 1mol / L sodium hydroxide solution to 1000ml of industrial grade acetone in turn, shake at room temperature for 10min, separate the acetone, add 135g of purification composition and heat to reflux until the purple color does not fade , then add anhydrous calcium sulfate, heat and reflux for 0.5h to dry, and finally carry out rectification at a flow rate of 20mL / min to collect fractions at 55-56.5°C to obtain 901ml of purified acetone with a purity of 99.503%;

[0019] Wherein, the purification composition is a composition of potassium permanganate, potassium perborate and iodine, and the mixing molar ratio thereof is 1:0.25:0.4.

Embodiment 2

[0021] Add 30ml of 0.75mol / L silver nitrate solution and 10ml of 1.5mol / L sodium hydroxide solution to 1000ml of industrial grade acetone, shake at room temperature for 15min, separate the acetone, add 140g of purification composition and heat to reflux until the purple color does not fade Then add anhydrous calcium sulfate, heat and reflux for 0.75h to dry, and finally carry out rectification at a flow rate of 15mL / min to collect fractions at 55-56.5°C to obtain 911ml of purified acetone with a purity of 99.512%;

[0022] Wherein, the purification composition is a composition of potassium permanganate, potassium perborate and iodine, the molar ratio of which is 1:0.5:0.6.

Embodiment 3

[0024] Add 35ml of 1mol / L silver nitrate solution and 15ml of 2mol / L sodium hydroxide solution to 1000ml of industrial grade acetone in turn, shake at room temperature for 20min, separate the acetone, add 145g of purification composition and heat to reflux until the purple color does not fade. Add anhydrous calcium sulfate and heat under reflux for 1 hour to dry, and finally carry out rectification at a flow rate of 10mL / min to collect fractions at 55-56.5°C to obtain 913ml of purified acetone with a purity of 99.515%;

[0025] Wherein, the purification composition is a composition of potassium permanganate, potassium perborate and iodine, the molar ratio of which is 1:0.1:0.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com