Method for brewing distilled spirit by using rice as raw material

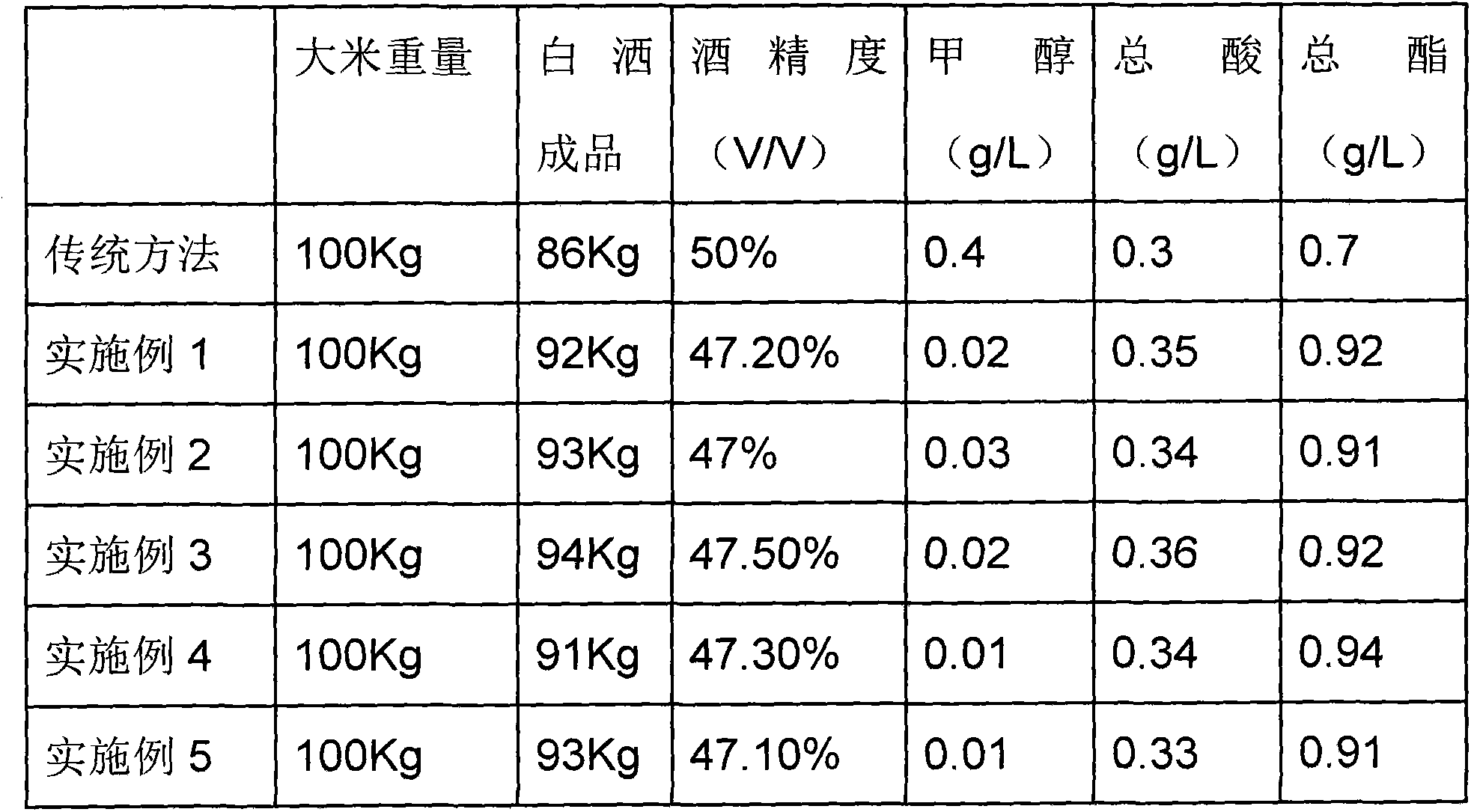

A rice and raw material technology, applied in the preparation of alcoholic beverages, etc., can solve the problems of low alcohol yield and high methanol content in liquor, and achieve the effects of improving quality, reducing methanol content, and increasing alcohol yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The liquor brewing method taking rice as raw material of the present embodiment comprises the following steps:

[0017] S1: Mix 100 kg of rice and 260 kg of water by weight, keep warm at 39 degrees, and let stand for 20 minutes;

[0018] S2: Mix 0.6 kg of white sugar and 0.6 kg of water by weight, keep warm at 32 degrees, add 0.3 kg of dry yeast, 0.3 kg of fresh aroma yeast, and 0.8 kg of distiller's yeast, and let it stand for 3 minutes;

[0019] S3: uniformly mix the materials obtained in steps S1 and S2, and place them in a stainless steel barrel for sealed fermentation;

[0020] S4: Ferment for 15 days, the first 8 days, open the fermenter every 12 hours, stir for 3 minutes before sealing;

[0021] S5: One-time distillation, stop distillation when the alcohol content of the detected fraction is 5% (V / V), and the obtained primary fraction is used for future use.

[0022] S6: Perform secondary distillation on the primary fraction obtained in S5, stop distillation wh...

Embodiment 2

[0024] The liquor brewing method taking rice as raw material of the present embodiment comprises the following steps:

[0025] S1: Mix 100 kg of rice and 270 kg of water by weight, keep warm at 40 degrees, and let stand for 30 minutes;

[0026] S2: Mix 0.6 kg of white sugar and 1 kg of water by weight, keep warm at 32.5 degrees, add 0.3 kg of dry yeast, 0.3 kg of fresh aroma yeast, and 0.8 kg of distiller's yeast, and let stand for 6 minutes;

[0027] S3: uniformly mix the materials obtained in steps S1 and S2, and place them in a stainless steel barrel for sealed fermentation;

[0028] S4: Ferment for 18 days, the first 9 days, open the fermenter every 12 hours, stir for 3-5 minutes before sealing;

[0029] S5: one distillation, the distillation is stopped when the alcohol content of the detected fraction is 8% (V / V), and the obtained primary fraction is used for future use.

[0030] S6: Perform secondary distillation on the primary fraction obtained in S5, stop distillatio...

Embodiment 3

[0032] The liquor brewing method taking rice as raw material of the present embodiment comprises the following steps:

[0033] S1: Mix 100 kg of rice and 280 kg of water by weight, keep warm at 42 degrees, and let stand for 40 minutes;

[0034] S2: Mix 0.6 kg of white sugar and 2 kg of water by weight, keep warm at 33 degrees, add 0.3 kg of dry yeast, 0.3 kg of fresh aroma yeast, and 0.8 kg of distiller's yeast, and let stand for 8 minutes;

[0035] S3: uniformly mix the materials obtained in steps S1 and S2, and place them in a stainless steel barrel for sealed fermentation;

[0036] S4: Ferment for 20 days, the first 10 days, open the fermenter every 12 hours, stir for 5 minutes before sealing;

[0037] S5: One-time distillation, stop distillation when the alcohol content of the detected fraction is 10% (V / V), and the obtained primary fraction is used for future use.

[0038] S6: Perform secondary distillation on the primary fraction obtained in S5, stop distillation when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com