Cherry health wine and making method thereof

The technology of cherry and fruit wine is applied in the field of cherry health-care fruit wine and its preparation, which can solve the problems of not bright enough color of fruit wine, low sugar content of cherry fruit, and low pigment content of fruit juice, etc., so as to achieve the goal of wide drinking population, thick taste and reduced miscellaneous The effect of bacterial interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

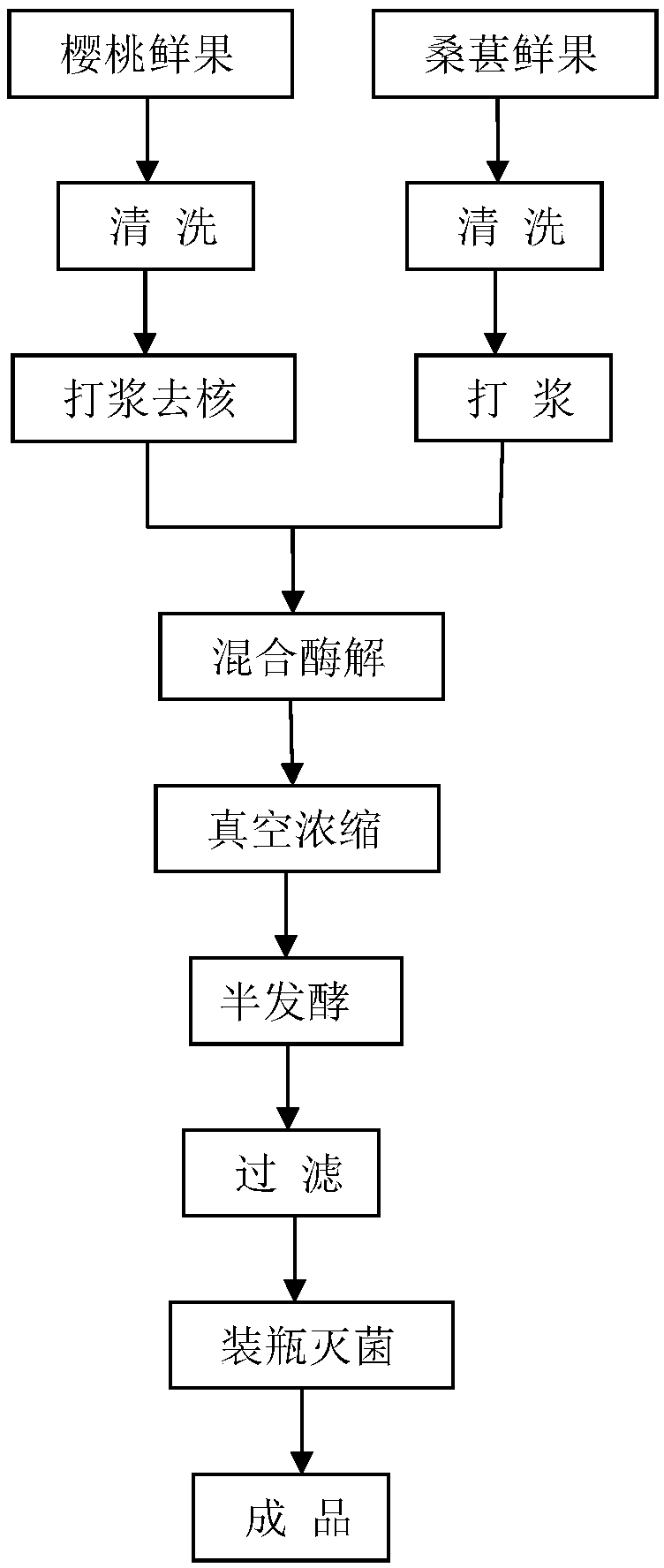

Image

Examples

Embodiment 1

[0040] 1. Beating

[0041] Take 1000kg of cherry fruit, wash it with clean water, beat through a scraper type beater, and get 850kg of berry pulp. Take 150 kg of mulberry fruit, wash it with clean water, and beat it with a scraper type beater to obtain 150 kg of fruit pulp.

[0042] 2. Enzyme hydrolysis

[0043] Mix 850 kg of cherry pulp with 150 kg of mulberry pulp, add 200 g of 100,000 U / g pectinase, heat to 45°C, and perform enzymatic hydrolysis for 30 minutes.

[0044] 3. Vacuum concentration

[0045] The enzymatic pulp is vacuum concentrated. The concentration temperature is 60±2°C, the vacuum degree is -0.07Mpa, and the concentration end point is 18°Brix of soluble solids.

[0046] (After testing, the methanol content of the mixed pulp before vacuum concentration was 426mg / L, and it was reduced to 162mg / L after vacuum concentration)

[0047] 4. UHT instantaneous sterilization

[0048] The concentrated fruit pulp is subjected to ultra-high temperature instantaneous ...

Embodiment 2

[0056] 1. Beating

[0057] Take 500kg of cherry fruit, wash it with clean water, beat through a scraper type beater, and get 400kg of berry pulp. Take 100kg of mulberry fruit, wash it with clean water, and beat it with a scraper type beater to obtain 100kg of fruit pulp.

[0058] 2. Enzyme hydrolysis

[0059] Mix 400 kg of cherry pulp with 100 kg of mulberry pulp, add 50 g of 100,000 U / g pectinase, heat to 50°C, and perform enzymatic hydrolysis for 60 minutes.

[0060] 3. Vacuum concentration

[0061] The enzymatic pulp is vacuum concentrated. The concentration temperature is 60±2°C, the vacuum degree is -0.05Mpa, and the end point of concentration is 17°Brix of soluble solids.

[0062] (After testing, the methanol content of the mixed pulp before vacuum concentration was 407mg / L, and it was reduced to 152mg / L after vacuum concentration)

[0063] 4. UHT instantaneous sterilization

[0064] The concentrated fruit pulp is subjected to ultra-high temperature instantaneous s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com