Process for extracting methanol using water in manufacturing of methyl methacrylate products

A technology of methyl methacrylate and methanol, which is applied in chemical instruments and methods, preparation of carboxylic acid esters, preparation of hydroxyl compounds, etc., and can solve the problem of high methanol content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

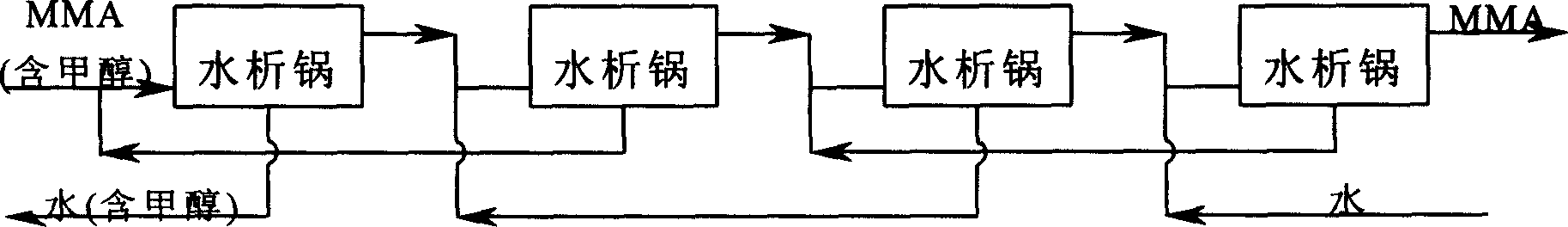

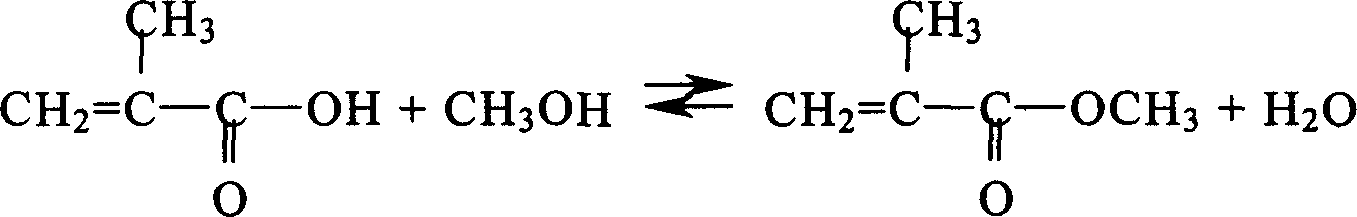

[0010] Extraction of methanol with water is generally carried out in a water analysis pot. From figure 1 It can be seen in the figure that the water analysis pot can be formed by connecting one or more pots in series. The more the pots are connected in series, the better the water extraction effect will be. When extracting, MMA (containing a small amount of methanol) and water enter the static mixer in proportion to make them fully contact with the extraction, and then enter the water analysis pot. Because MMA is slightly soluble in water, the proportion difference between the two is relatively large, and relatively static stratification is carried out in the water analysis pot. The upper layer is the extracted MMA monomer, which enters the next water analysis pot through the overflow port, and the lower layer is water ( The solution containing methanol) is pumped into the last water analysis pot by the metering pump. After several water analysis pots and several times of wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com