Preparation method of epoxypropane

A technology of propylene oxide and epoxidation reaction, which is applied in the fields of organic chemistry and bulk chemical production, and can solve problems such as the difficulty in obtaining high-purity propylene oxide and the inability to effectively separate propylene oxide and methanol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

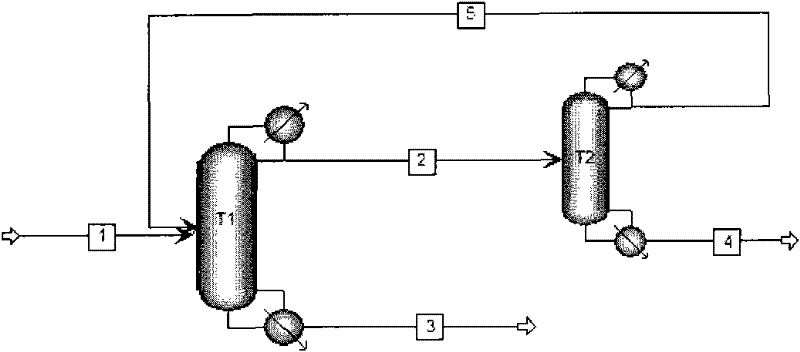

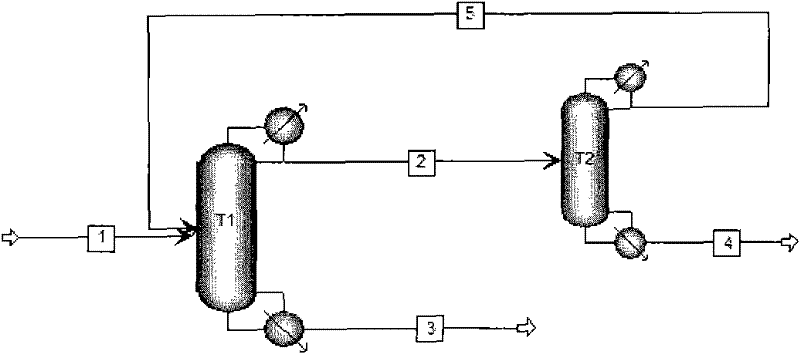

[0013] The preparation method of described propylene oxide provided by the invention comprises the following steps:

[0014] (1) Under the propylene epoxidation reaction conditions, in the presence of a solid catalyst, make the mixed material containing methanol, propylene and hydrogen peroxide pass through the first reactor and the second reactor successively;

[0015] (2) under the first azeotropic rectification condition, the propylene oxide crude product obtained in step (1) is sent in the first azeotropic rectification tower, and this first azeotropic rectification condition makes propylene oxide and Part of the methanol is extracted from the top of the tower in the form of azeotrope, and the remaining part of the methanol is extracted from the bottom of the tower, and the content of propylene oxide in the bottom effluent of the first azeotropic rectification tower is not higher than 5% by weight;

[0016] (3) Under the second azeotropic rectification condition, the azeot...

Embodiment approach

[0032] According to another embodiment of the present invention, the first azeotropic distillation conditions may also include that the bottom temperature of the first azeotropic distillation column is 100-140°C, preferably 100-130°C; the reflux ratio is 2 -5:1. The second azeotropic distillation conditions may also include that the bottom temperature of the second azeotropic distillation column is 110-130° C., preferably 110-120° C.; the reflux ratio is 0.8-3:1.

[0033] In the present invention, the first azeotropic rectification tower and the second azeotropic rectification tower can each be a packed tower, a tray tower or a composite tower of packing and trays.

[0034] The packing packed in the described packed tower can be various packings known to those skilled in the art, for example this packing can be selected from Raschig ring, Pall ring, stepped ring, saddle ring, arc saddle type, rectangular saddle type, One or more of θ mesh ring, calendered hole ring, plate cor...

preparation example 1

[0043] Preparation Example 1: Preparation of Ti-Si Molecular Sieve Catalyst

[0044] 100 grams of titanium-silicon molecular sieve powder (purchased from Hunan Jianchang Co., Ltd., brand HTS), 1 gram of magnesium oxide and 40 grams of tetramethoxysilane are mixed uniformly, and then 20 grams of silica sol (SiO 2 The content is 30% by weight), 2 grams of polyvinyl alcohol, 1 gram of Sesame powder (purchased from Dongming County Zhuwa Tianjing Glue Factory) and 20 milliliters of water, mixed evenly and extruded into strips, the size is 2× 2 mm, and then dried at 70°C for 4 hours to obtain molding A.

[0045]Take 100 grams of molding A and put it into a three-necked bottle, add 200ml of 20% by weight sodium hydroxide solution, heat to 90°C and keep it warm for 6 hours, then wash with deionized water until the washing water does not contain sodium ions until. Then, it was dried at 120°C for 3 hours, and fired at 550°C for 3 hours to obtain a fired product B.

[0046] Get 100 gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com