Underwater super-oleophobic oil-water separation mesh membrane as well as preparation method and application thereof

An oil-water separation omentum membrane, underwater superoleophobic technology, which is applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of unsuitable separation, high-temperature curing, complicated manufacturing process, etc., and achieves low preparation cost, Good stability and fast oil-water separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) immerse the 300-mesh stainless steel wire mesh respectively in ethanol and acetone for ultrasonic cleaning for 5 minutes, and dry at room temperature;

[0040] (2) At room temperature, add 20ml of water, 6g of acrylamide, 0.24g of N,N'-methylenebisacrylamide, 0.1g of polyacrylamide and 0.18g of 2,2-diethoxy Acetophenone was mixed evenly by magnetic stirring to obtain a mixed solution;

[0041] (3) uniformly coating the mixed solution obtained in step (2) on the surface of the stainless steel wire mesh after step (1) is dried;

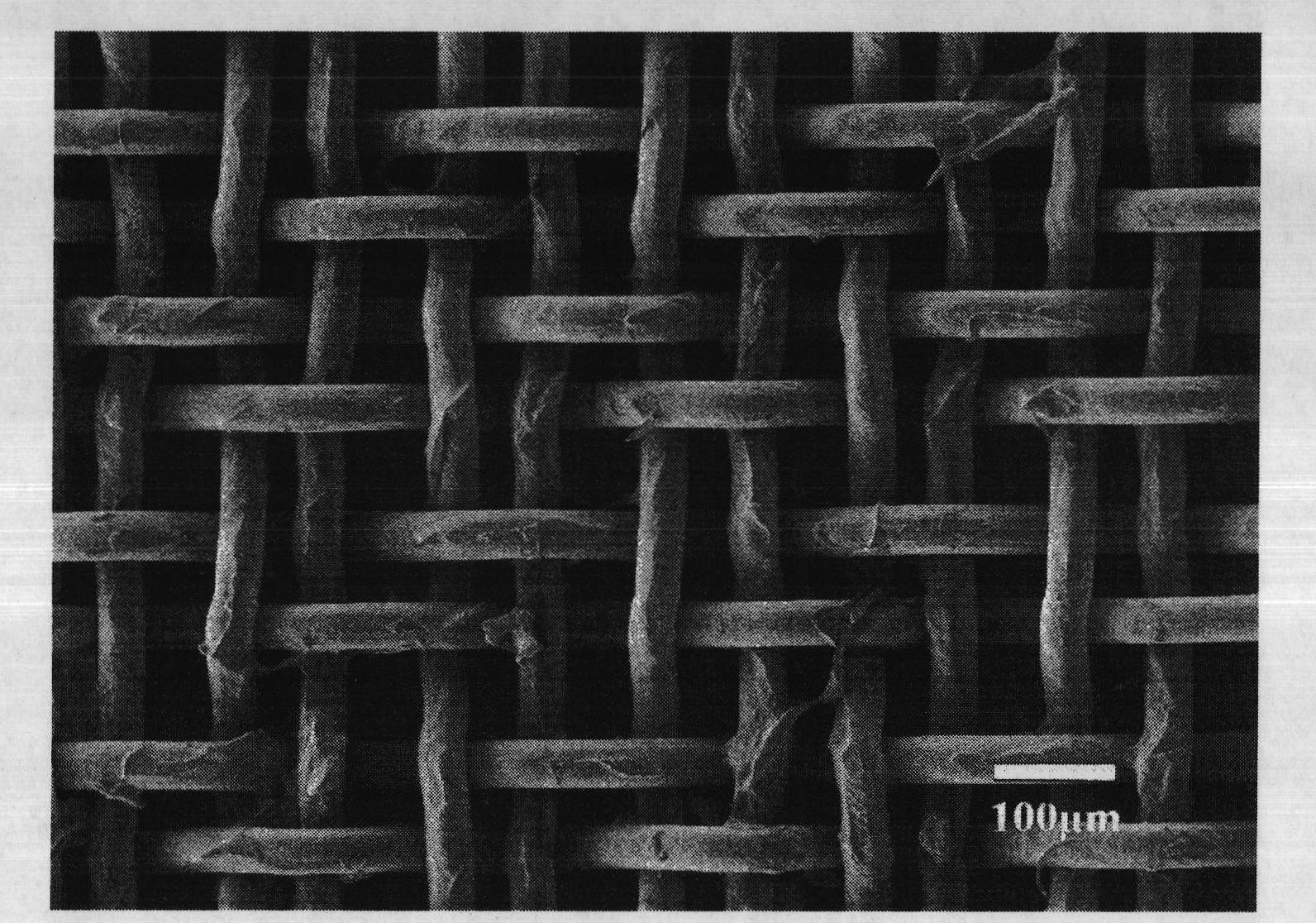

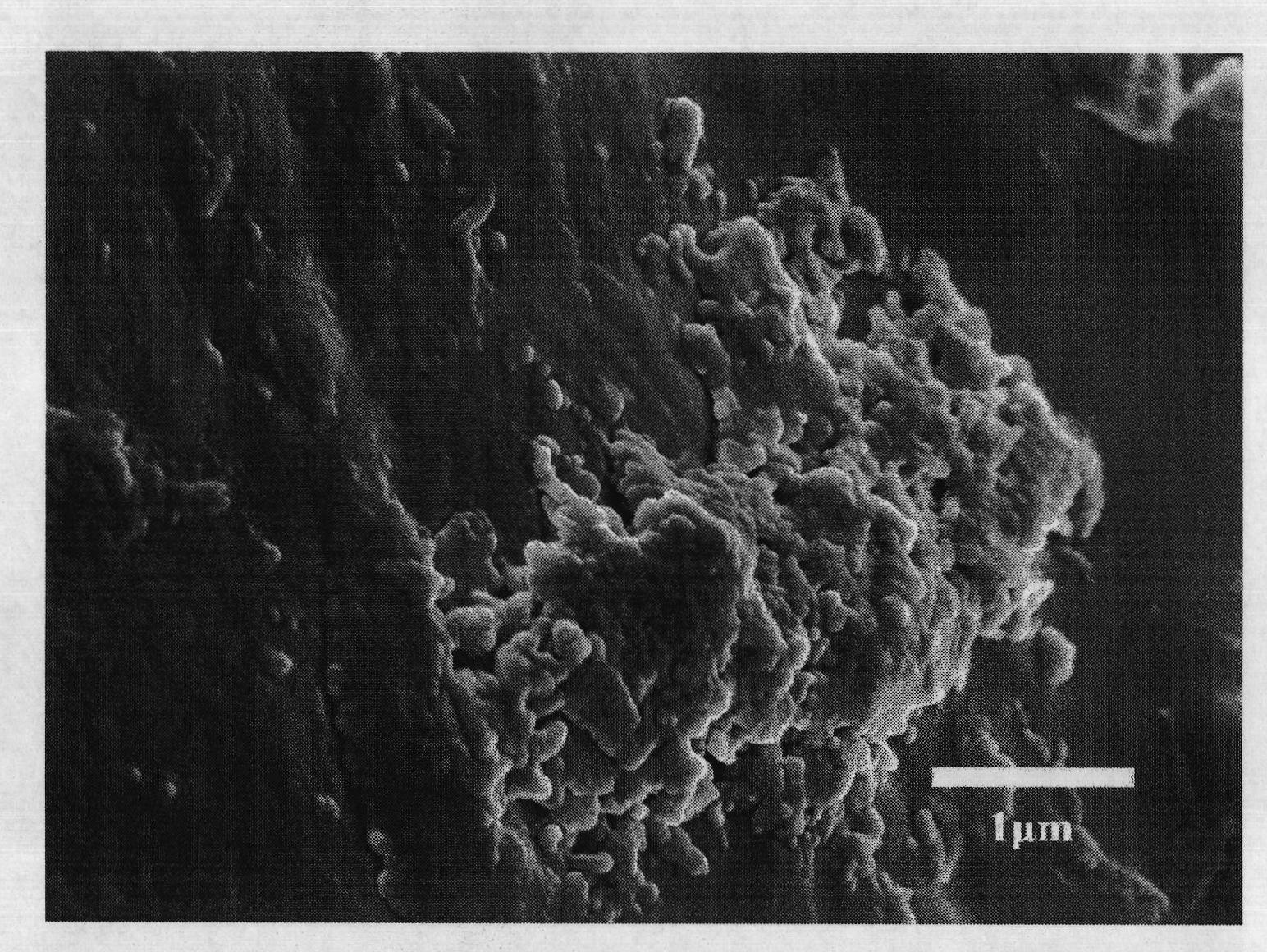

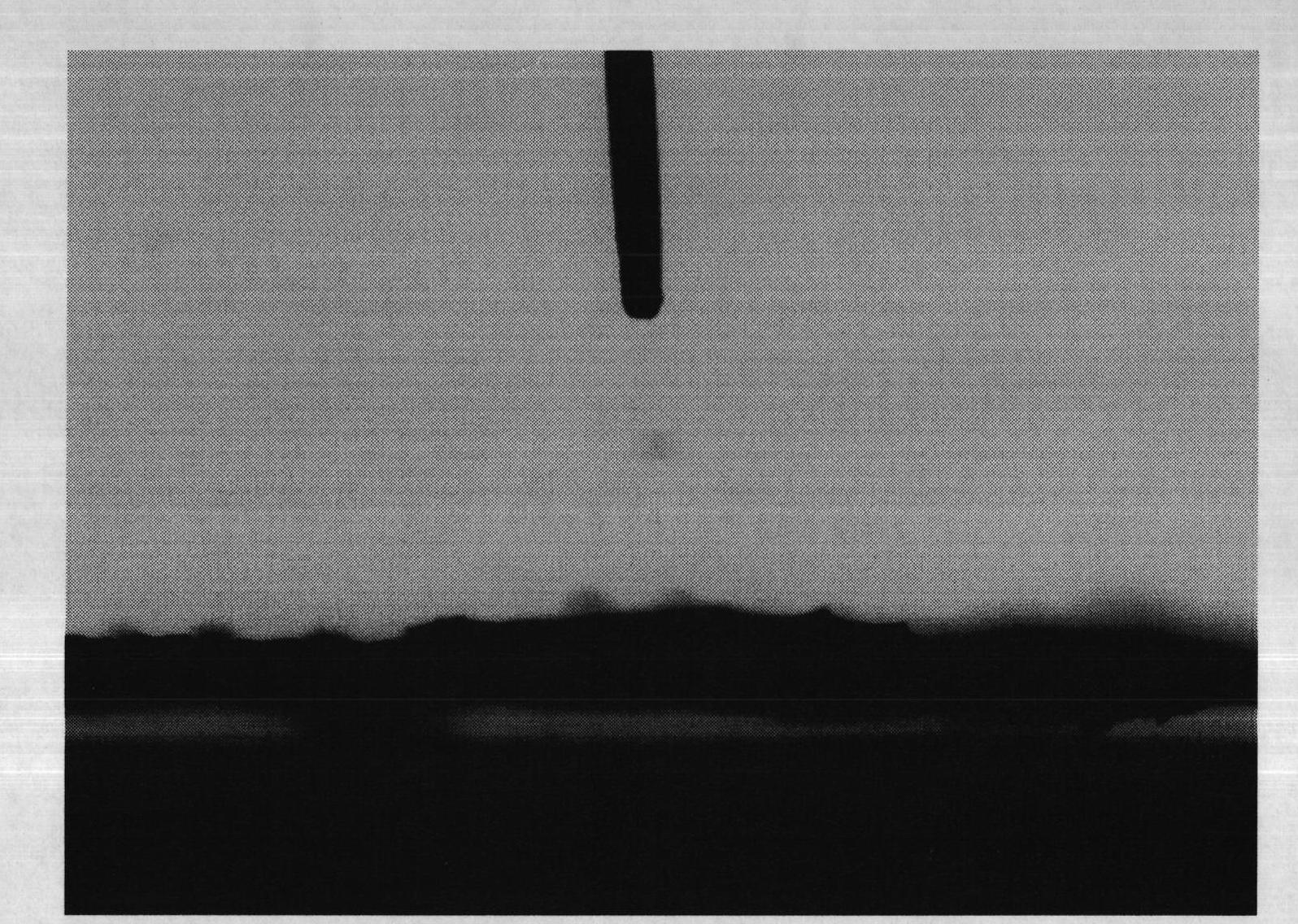

[0042] (4) With a wavelength of 365nm ultraviolet light source irradiation step (3) coated stainless steel wire mesh mixed solution for 90 minutes, so that the acrylamide monomer and N, N'-methylenebisacrylamide crosslinking agent in the initiator Under the effect of 2,2-diethoxyacetophenone, cross-linking polymerization occurs, and a polyacrylamide hydrogel layer with a thickness of 2 microns (such as Figure 1a shown), on the polyacrylamid...

Embodiment 2

[0046] (1) The 100-mesh copper grid was respectively immersed in ethanol and acetone for ultrasonic cleaning for 5 minutes, and dried at room temperature;

[0047] (2) At room temperature, add 20ml of water, 5.5g of acrylic acid, 0.1g of N,N'-methylenebisacrylamide, 0.15g of polyvinyl alcohol and 0.15g of 2,2-diethoxybenzene into a 50ml Erlenmeyer flask Ethyl ketone, mixed evenly by magnetic stirring;

[0048] (3) uniformly coating the mixed solution obtained in step (2) on the copper mesh surface after step (1) dries;

[0049] (4) irradiating step (3) with an ultraviolet light source with a wavelength of 365nm on the copper grid coated with the mixed solution for 60 minutes, so that the acrylic acid monomer and N, N'-methylenebisacrylamide crosslinking agent are in the initiator 2, Under the action of 2-diethoxyacetophenone, cross-linking polymerization occurs, and a polyacrylic acid hydrogel layer with a thickness of 9.5 microns is formed on the surface of the copper wire o...

Embodiment 3

[0053] (1) 400-mesh nylon nets were respectively immersed in ethanol and acetone for ultrasonic cleaning for 5 minutes, and dried at room temperature;

[0054] (2) At room temperature, add 20ml of water, 13g of N-ethylacrylamide, 0.21g of N,N'-methylenebisacrylamide, 0.09g of polyvinylpyrrolidone and 0.3g of 2,2-bisacrylamide into a 50ml Erlenmeyer flask Ethoxylated acetophenone, mixed evenly by magnetic stirring.

[0055] (3) uniformly coating the mixed solution obtained in step (2) on the surface of the nylon mesh after step (1) is dried;

[0056] (4) Irradiating step (3) with a UV light source with a wavelength of 365nm on the copper grid coated with the mixed solution for 100 minutes to make N-ethylacrylamide monomer and N, N'-methylenebisacrylamide crosslinking agent Under the action of the initiator 2,2-diethoxyacetophenone, cross-linking polymerization occurs, and a poly N-ethylacrylamide hydrogel layer with a thickness of 1.5 microns is formed on the surface of the ny...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com