Method and apparatus for circulating, desorbing, shunting, recovering, and reclaiming hot gas by using adsorption bed

A technology of hot gas circulation and regeneration device, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of difficulty in amplification, affecting the control of the temperature of the adsorption bed, etc., to reduce equipment investment and energy consumption, facilitate refining and recovery, Conducive to the effect of condensation separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

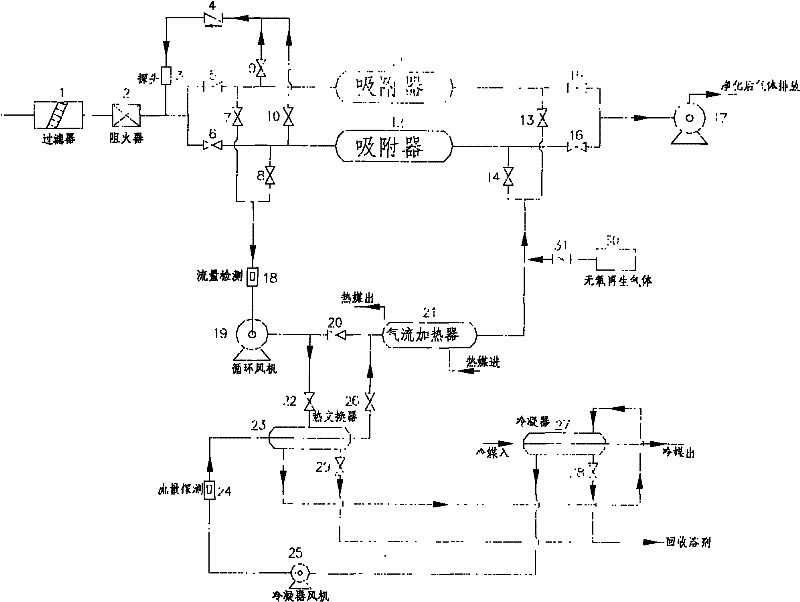

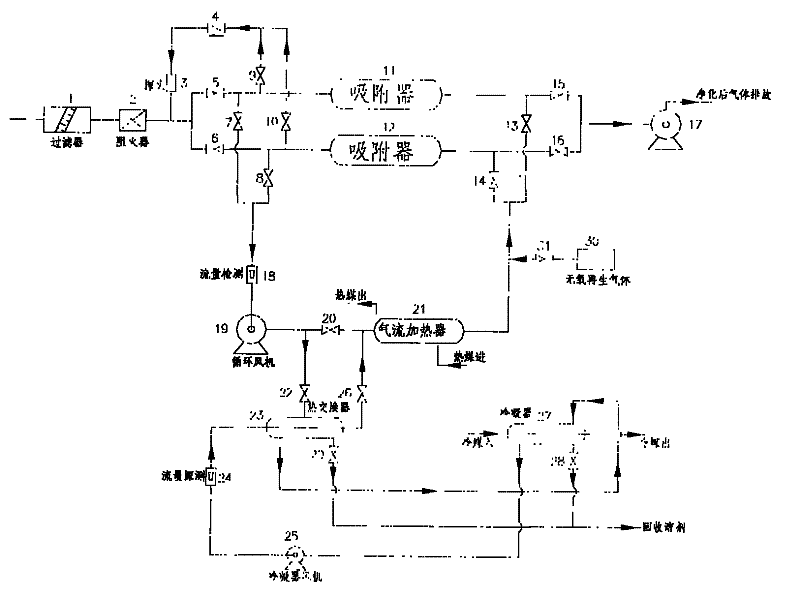

[0034] Press the following parts to figure 1 Those skilled in the art can successfully implement the connection in the manner shown. The device of the present invention consists of a gas filter adopting AF5-N type, a flame arrester adopting mesh type HGS07, two adsorbers filled with adsorbent adopting CAU5-G type, a main fan adopting BF9-26NO5A type, and a thermal The exchanger adopts AAE-2-B type, a circulating air heater adopts GL-5 type, a gas condenser adopts TLS-10-12-400 type, and a circulating fan adopts BF9-264A type, etc. The gas source 31 is nitrogen gas, the oxygen content measuring probe 3 is a TB2A zirconia oxygen probe, the automatic control system is a PLC program controller, and the program-controlled valve is a KVD pneumatic disc valve.

[0035] When the system is running, the toluene-containing exhaust gas is removed by the filter 1, and then enters the subsequent recovery and regeneration system through the flame arrester 2. The following uses the adsorber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com