Technique for extracting high-pure normal hexane product by pressure swing adsorption

A pressure swing adsorption, n-hexane technology, applied in adsorption purification/separation, organic chemistry and other directions, can solve the problems of low yield, high energy consumption of rectification, complex process, etc., and achieve simple equipment, simple process and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

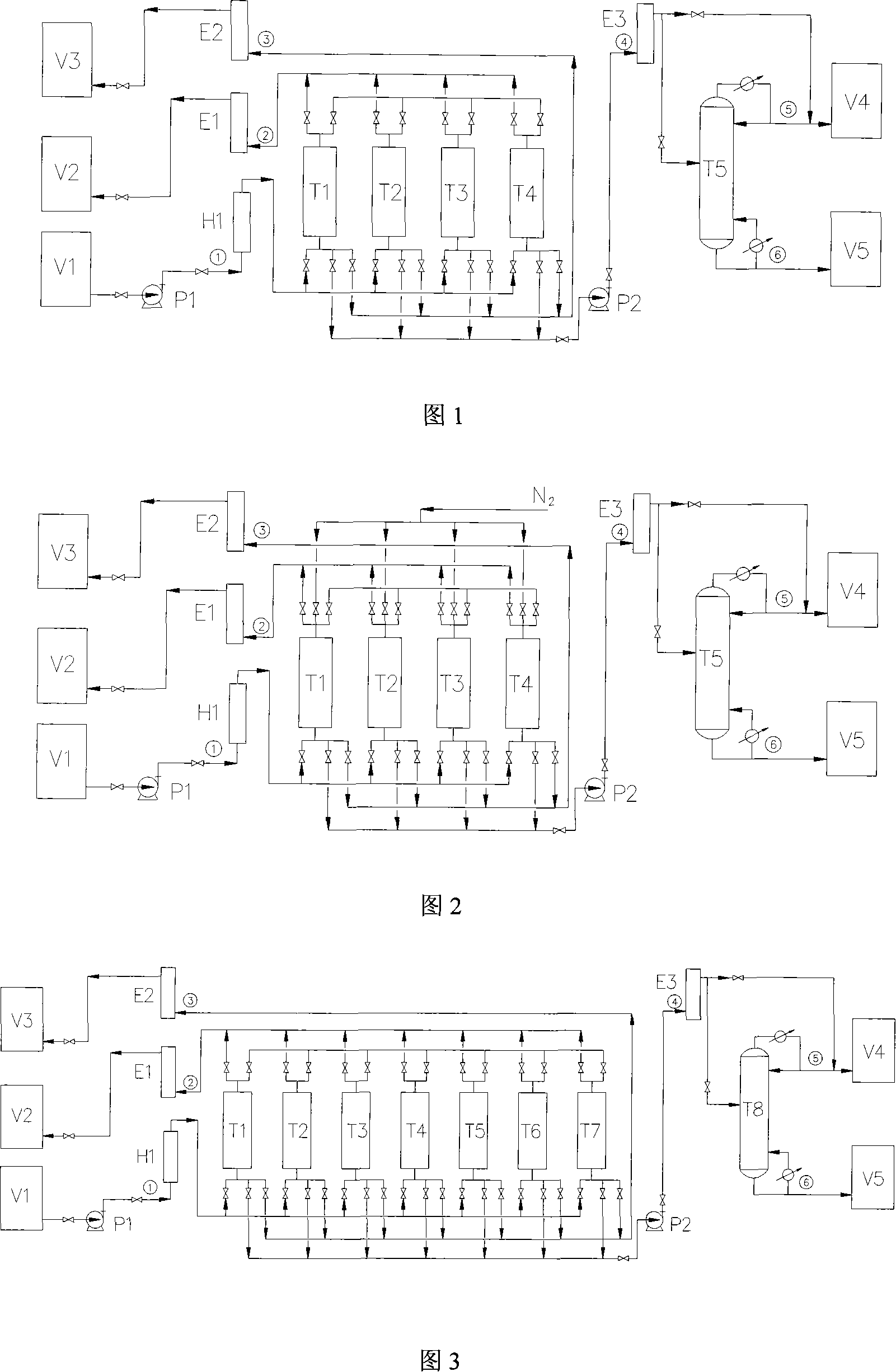

[0017] Example 1: Industrial hexane is used as raw material, SAPO-34 molecular sieve is used as adsorbent, the typical composition of industrial hexane is shown in Table 1, and the schematic diagram of the four-tower pressure swing adsorption process is shown in Figure 1.

[0018] Table 1 Composition of industrial hexane

[0019] Compound name

Content (wt%)

2,3-Dimethylbutane

2-Methylpentane

0.56

4.08

[0020] 3-Methylpentane

n-Hexane

2,2-Dimethylpentane

2,4-Dimethylpentane

2,2,3-Trimethylbutane

20.49

62.10

0.58

11.85

0.16

0.01

0.20

[0021] The four-tower (T1, T2, T3, T4) pressure swing adsorption cycle process and time distribution are shown in Table 2. A pressure swing adsorption cycle period is 16 minutes, of which the adsorption is 4 minutes, the average pressure drop is 2 minutes, the pressure i...

Embodiment 2

[0026] Embodiment 2, as shown in Figure 2. The pressure swing adsorption process, specific operation process and steps are the same as in Example 1, the difference is that the adsorption temperature is 120°C, and the desorption adopts vacuuming while using N 2 Purging, desorption pressure is 50kPa.

Embodiment 3

[0027] In Example 3, No. 6 solvent oil was used as the raw material, and 5A molecular sieve was used as the adsorbent. The composition of No. 6 solvent oil is shown in Table 3, and the schematic diagram of the seven-tower pressure swing adsorption process is shown in Fig. 3 .

[0028] Table 3 Composition of No. 6 solvent oil

[0029] Compound name

Content (wt%)

2,2-Dimethylbutane

2,3-Dimethylbutane

2-Methylpentane

3-Methylpentane

n-Hexane

2,2-Dimethylpentane

2,4-Dimethylpentane

2,2,3-Trimethylbutane

3,3-Dimethylpentane

2-Methylhexane

2,3-Dimethylpentane

3-Methylhexane

1.43

6.27

27.51

21.71

25.26

2.57

3.73

2.64

0.42

1.51

0.84

2.75

1.26

2.01

[0030] The seven towers (T1, T2, T3, T4, T5, T6, T7) pressure swing adsorption cycle process and time distribution are shown in Table 4. A pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com