Preparation method of MOFs tube type hybrid membrane for separating aromatic hydrocarbons/alkyl hydrocarbons

A technology for separating aromatic hydrocarbons and hybrid membranes, applied in the field of membrane separation, can solve the problems of high temperature resistance, high manufacturing cost, brittleness and difficult processing, etc., and achieve the effect of improving swelling resistance and reducing feeding temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

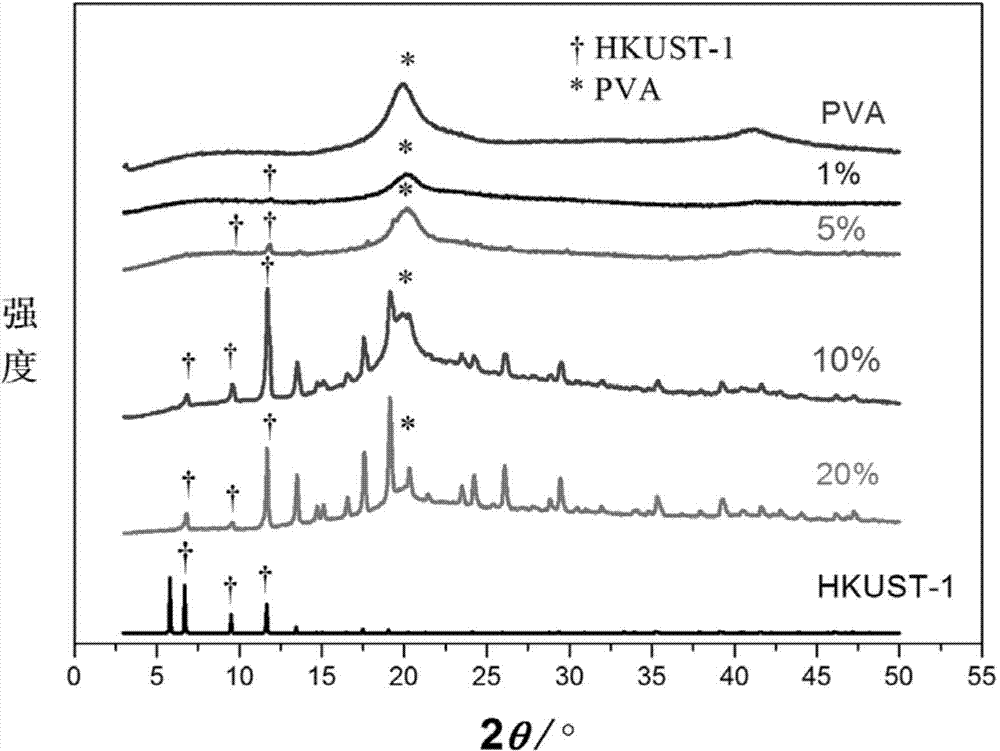

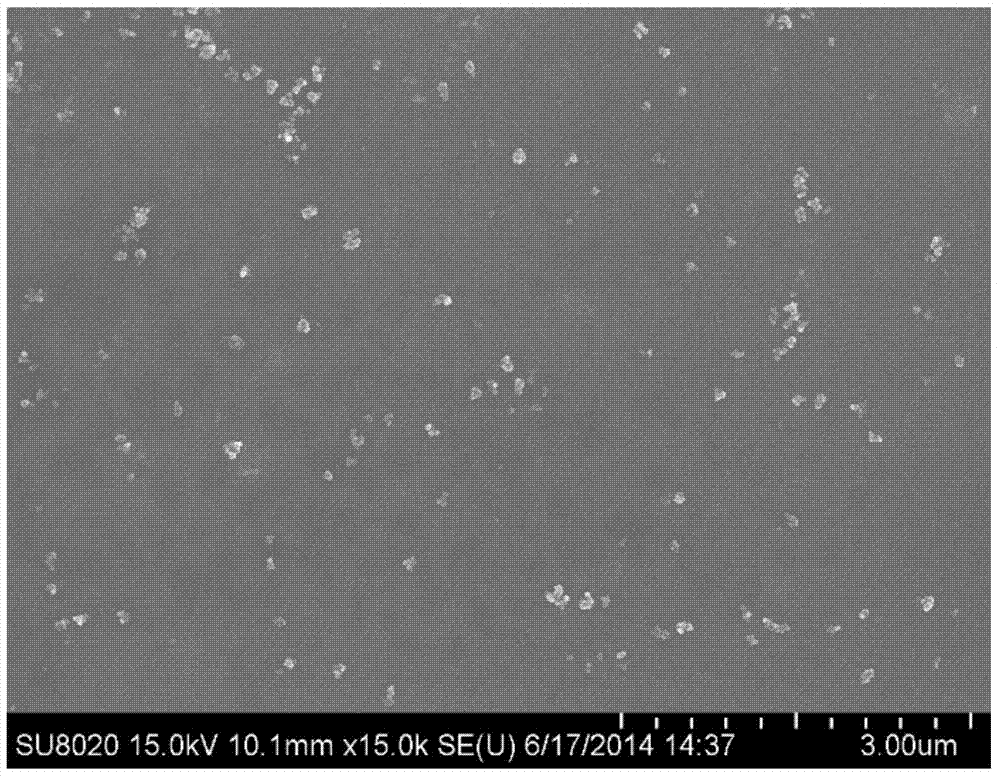

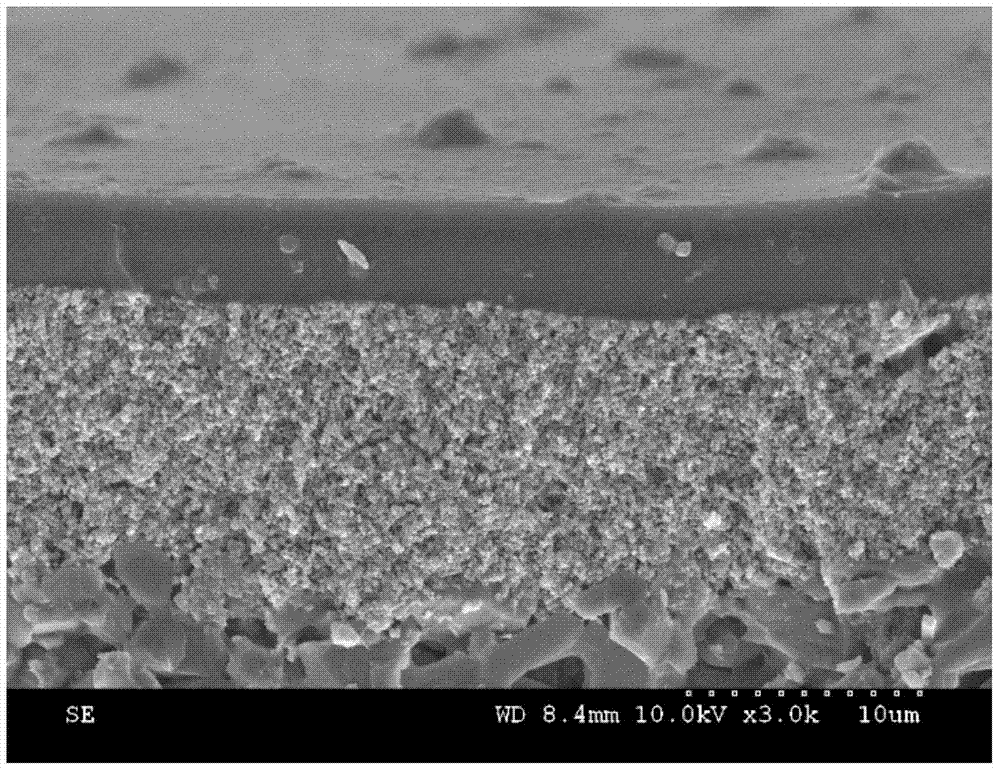

[0026] Aluminum oxide (Al 2 o 3 ) material, in the form of a tubular ultrafiltration membrane with a membrane pore size of 0.1-0.2 μm and a membrane area of 28 cm 2 , the silane coupling agent used in pretreatment is 3-aminopropyl-trimethoxysilane, the polymer with hydroxyl used is polyvinyl alcohol (PVA, molecular weight is 16000), and the metal source is copper acetate hydrate ((CH 3 COO) 2 Cu·H 2 O, the molecular weight is 199.65), and the organic ligand is trimesic acid (C 9 h 6 0 6 , the molecular weight is 210), the solvent of the metal source and the organic ligand is H at a ratio of 1:1:1 2 O, C 2 h 5 The mixed solution of OH and DMF, the solvent of polyvinyl alcohol is H 2 O.

[0027] Preparation conditions and methods:

[0028] (1) Prepare HKUST-1 by solvothermal method. Dissolve 5 g of copper acetate hydrate and 2.5 g of trimesic acid in H at a ratio of 1:1:1 2 O, C 2 h 5 OH, DMF solvent, prepared into a solution, static defoaming. It was stirred a...

Embodiment 2

[0036]Aluminum oxide (Al 2 o 3 ) material, in the form of a tubular ultrafiltration membrane with a membrane pore size of 0.1-0.2 μm and a membrane area of 28 cm 2 , the silane coupling agent used in pretreatment is 3-aminopropyl-trimethoxysilane, the polymer with hydroxyl used is polyvinyl alcohol (PVA, molecular weight is 16000), and the metal source is copper acetate hydrate ((CH 3 COO) 2 Cu·H 2 O, the molecular weight is 199.65), and the organic ligand is trimesic acid (C 9 h 6 0 6 , the molecular weight is 210), the solvent of the metal source and the organic ligand is H at a ratio of 1:1:1 2 O, C 2 h 5 The mixed solution of OH and DMF, the solvent of polyvinyl alcohol is H 2 O.

[0037] Preparation conditions and methods:

[0038] (1) Prepare HKUST-1 by solvothermal method. Dissolve 5 g of copper acetate hydrate and 2.5 g of trimesic acid in H at a ratio of 1:1:1 2 O, C 2 h 5 OH, DMF solvent, prepared into a solution, static defoaming. It was stirred at...

Embodiment 3

[0046] Aluminum oxide (Al 2 o 3 ) material, in the form of a tubular ultrafiltration membrane with a membrane pore size of 0.1-0.2 μm and a membrane area of 28 cm 2 , the silane coupling agent used in pretreatment is 3-aminopropyl-trimethoxysilane, the polymer with hydroxyl used is polyvinyl alcohol (PVA, molecular weight is 16000), and the metal source is copper acetate hydrate ((CH 3 COO) 2 Cu·H 2 O, the molecular weight is 199.65); the organic ligand is trimesic acid (C 9 h 6 0 6 , the molecular weight is 210), the solvent of the metal source and the organic ligand is H at a ratio of 1:1:1 2 O, C 2 h 5 The mixed solution of OH and DMF, the solvent of polyvinyl alcohol is H 2 O.

[0047] Preparation conditions and methods:

[0048] (1) Prepare HKUST-1 by solvothermal method. Dissolve 5 g of copper acetate hydrate and 2.5 g of trimesic acid in H at a ratio of 1:1:1 2 O, C 2 h 5 OH, DMF solvent, prepared into a solution, static defoaming. It was stirred at ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore size | aaaaa | aaaaa |

| Membrane pore size | aaaaa | aaaaa |

| Membrane area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com