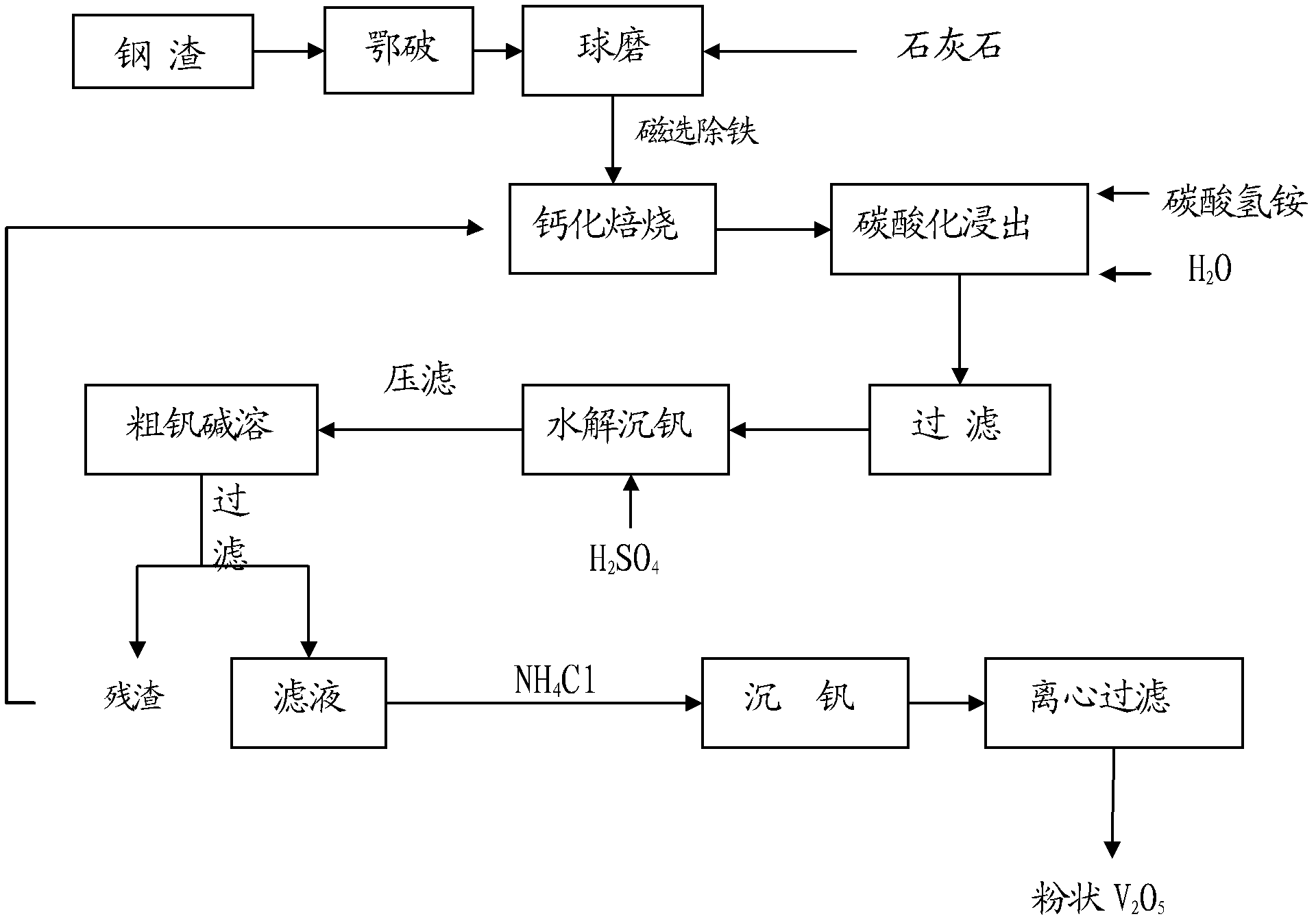

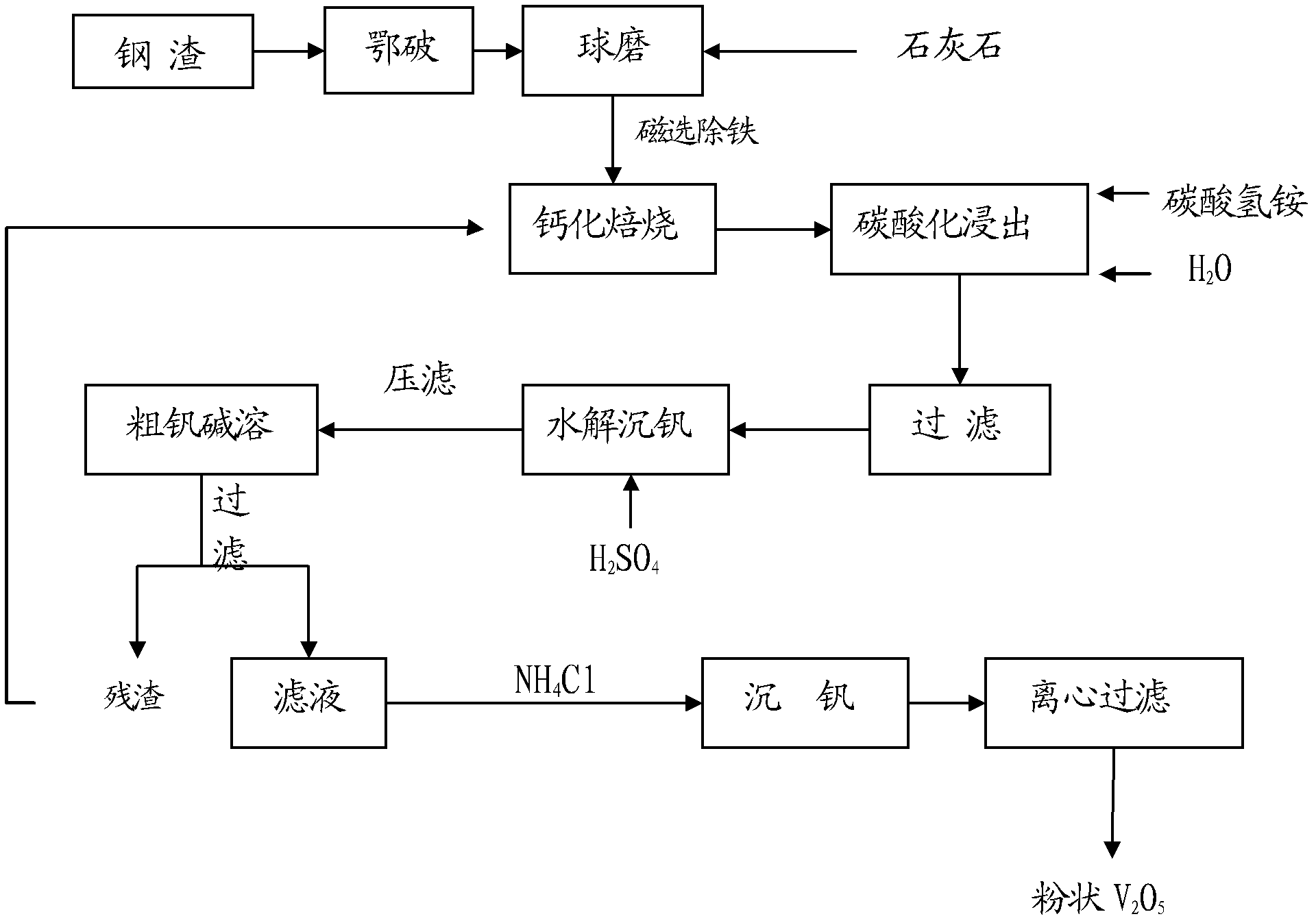

Vanadium extraction technology of low-grade high-calcium vanadium-containing steel slag

A low-grade, steel slag technology, applied in the field of metallurgy and chemical industry, can solve problems such as difficult extraction of vanadium, and achieve the effect of avoiding interference and influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] S1-1. Obtaining steel slag: direct steelmaking with vanadium-containing molten iron, and vanadium will enter the steel slag during the steelmaking process to obtain low-grade, high-calcium, vanadium-containing steel slag. The low-grade high-calcium vanadium-containing steel slag is first crushed by jaw crusher, and lime is added according to the CaO mass ratio of 7%±1%, and the mixed material is mixed and ground to -200 mesh±10 mesh. The vanadium slag is obtained after iron removal by magnetic separation. The metal iron contained in the vanadium slag is less than 5%, mainly to prevent the iron from exothermic and causing the charge to stick in the subsequent roasting process. Finally, the vanadium slag is granulated, and the particle size is 10mm±1mm.

[0028] S1-2, carry out calcification roasting on the granular vanadium slag in S1-1, the roasting temperature in the rotary kiln is 950℃±50℃, and the duration is 2-3h. Through roasting, the vanadium in the vanadium slag...

Embodiment 2

[0034] S2-1. Use vanadium-containing molten iron to directly make steel. During the steelmaking process, vanadium will enter the steel slag to obtain low-grade and high-calcium vanadium-containing steel slag, so as to realize the pretreatment of the steel slag. The low-grade and high-calcium vanadium-containing steel slag is first crushed by jaw type, and lime is added according to the CaO with a mass ratio of 7%, and the mixed material is mixed and ground to -200 mesh. The vanadium slag is obtained after iron removal by magnetic separation. The metal iron contained in the vanadium slag is less than 5%, mainly to prevent the iron from exothermic and causing the charge to stick in the subsequent roasting process. Finally, the vanadium slag is granulated, and the particle size is 10 mm.

[0035] S2-2, carry out calcification roasting on the granular vanadium slag in S2-1, the roasting temperature in the rotary kiln is 950℃, and the duration is 2.5h. Through roasting, the vanadi...

Embodiment 3

[0041] The process steps of this embodiment and the first embodiment are the same, and the difference lies in the parameters required for each step, which are as follows:

[0042] S3-1. Add lime according to the mass ratio of lime to low-grade high-calcium vanadium-containing steel slag as 6%, and mix and grind the mixture to -210 mesh; the obtained vanadium slag is granulated, and the particle size is 9 mm;

[0043] S3-2, the vanadium slag is subjected to calcification roasting at a temperature of 900°C and a duration of 2h;

[0044] S3-3, Ca(VO 3 ) 2 Mix with 5% ammonium bicarbonate aqueous solution according to the ratio of liquid to solid ratio of 1.8:1;

[0045] S3-4, hydrolyze vanadium precipitation at 95℃ for 1.5h;

[0046] S3-5, the same as S1-5;

[0047] S3-6, NH 4 Cl:V 2 O 5 =1.8:1, precipitation at room temperature for 11.5h; the obtained NH 4 VO 3 Deamination at 500°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com