Copper-containing beta molecular sieve and preparation method thereof

A technology of beta molecular sieve and copper content, applied in the field of beta molecular sieve and its preparation, can solve problems such as variation, limitation of ion exchange species, and structural damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] In the preparation method provided by the present invention, the copper-containing compound is selected from copper nitrate, copper chloride, cuprous chloride, copper sulfate, copper acetate, copper ammonia solution, copper hydroxide and other compounds containing monovalent or divalent copper One or more of them. Preferred copper-containing compounds are copper chloride and copper hydroxide, and copper hydroxide is more preferred. In the first method, the copper-containing compound and the ammonium-type β molecular sieve are charged with a molar ratio of copper to aluminum of 1:0.1 to 1:10, more preferably 1:0.1 to 1:4. In the second method, the copper-containing compound and the The feed ratio of the ammonium type β molecular sieve is that the molar ratio of copper to aluminum is 1:0.5 to 1:10, more preferably 1:0.5 to 1:4, the ammonium type β molecular sieve is calculated as aluminum, and the copper-containing compound is calculated as copper.

[0029] In the preparati...

Embodiment 1

[0041] Weigh 0.61 g of copper chloride dihydrate, add 500 g of water to form a copper chloride aqueous solution, and add 0.48 g of 25% concentrated ammonia water dropwise to prepare a copper hydroxide gel. Weigh 20g of NH containing template 4 The β molecular sieve was stirred and mixed with it at room temperature, filtered, washed, and the filter cake was dried and placed in a muffle furnace. In an air atmosphere, the temperature was raised from room temperature to 400°C, and the mixture was calcined at 400°C for 4 hours to obtain sample S1.

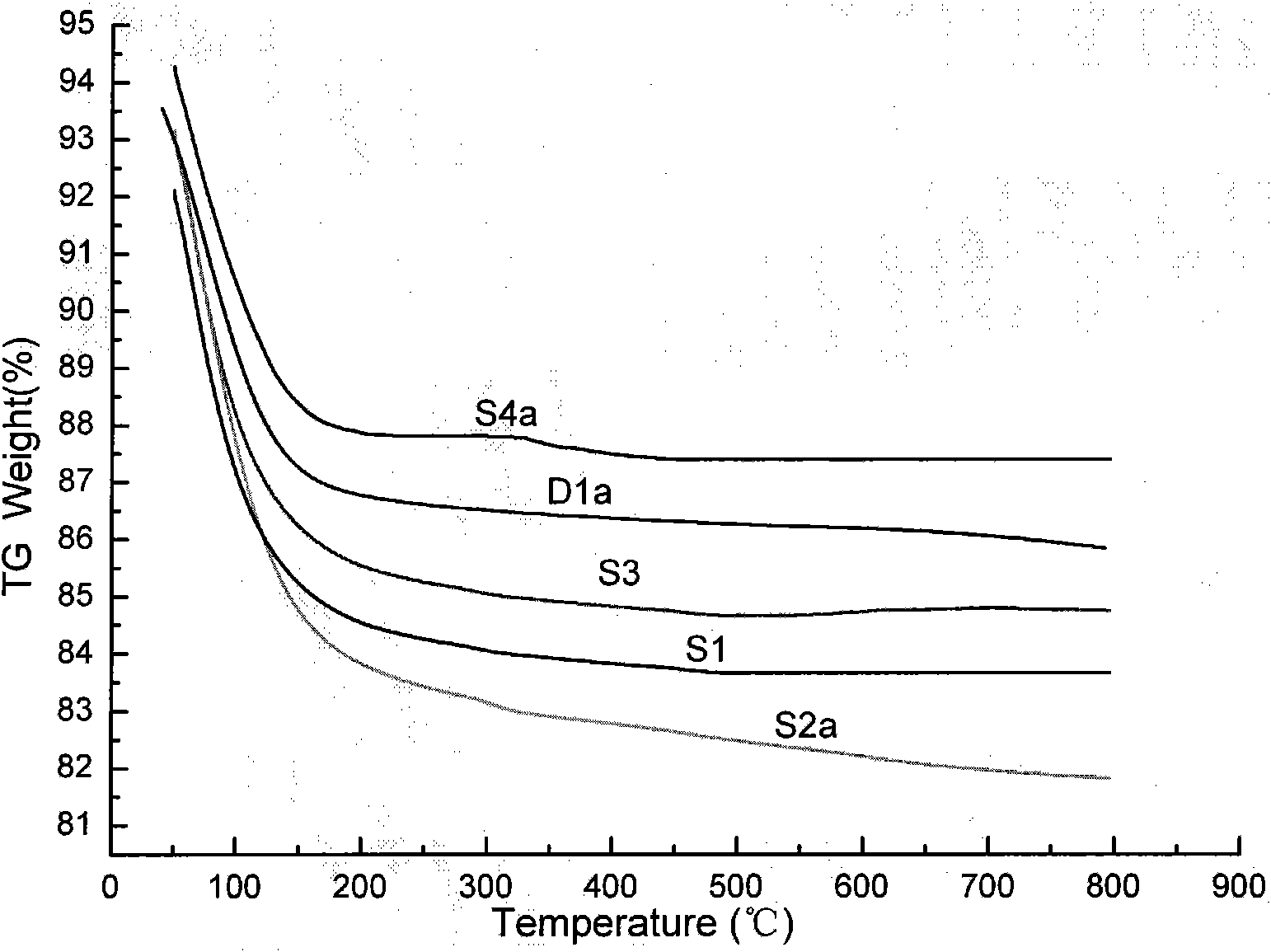

[0042] The thermogravimetric analysis diagram of sample S1 is attached figure 1 The S1 curve shows that the organic amine template is removed cleanly.

[0043] Sample S1 was analyzed by X-ray fluorescence method, and the copper content was 2.06% by weight based on CuO.

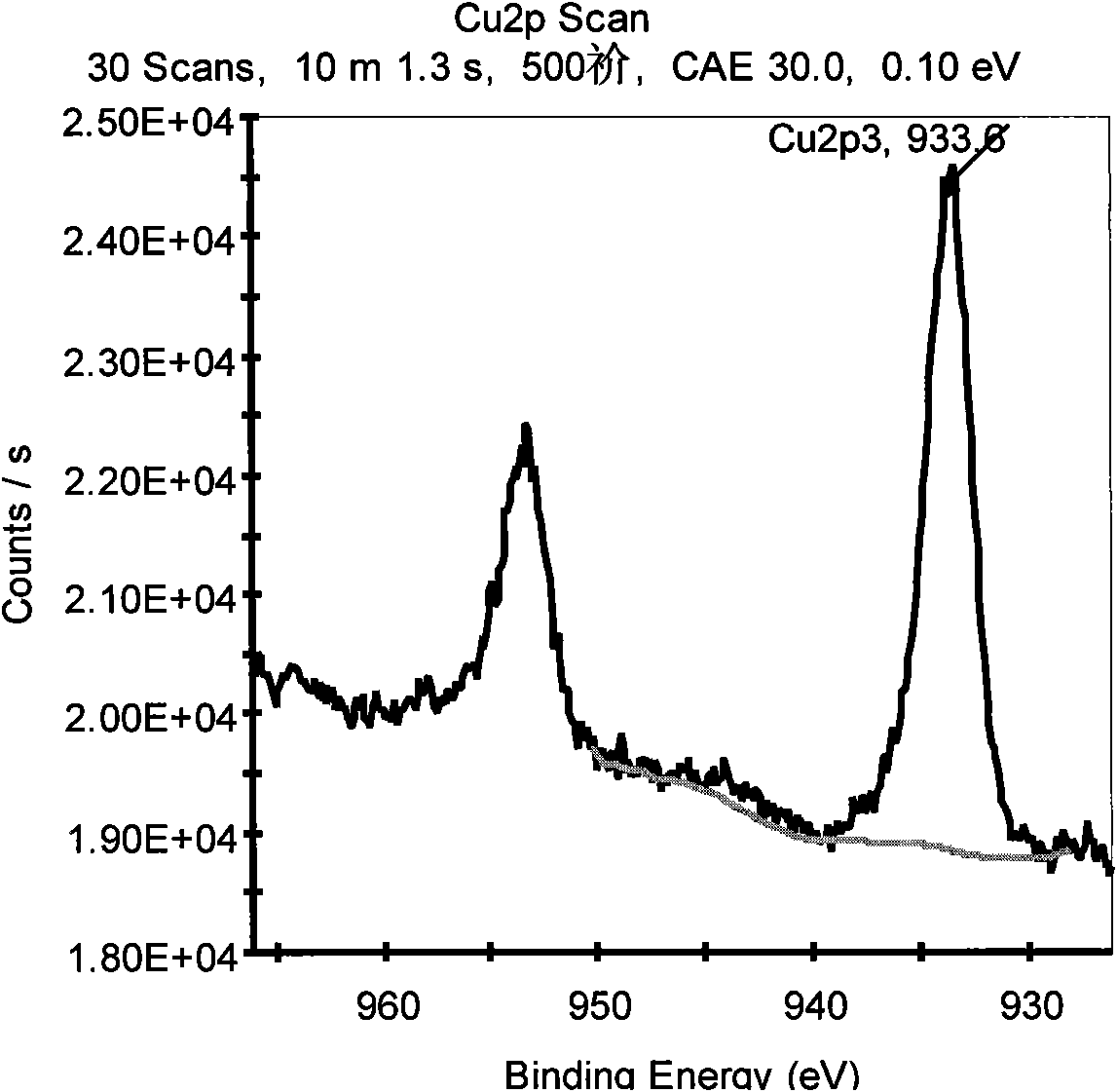

[0044] The X-ray photoelectron spectrum of sample S1 is shown in figure 2 , See the split peak spectrum Figure 7 , Where Cu + / (Cu + +Cu 2+ ) The content is 81.78.

Embodiment 2

[0046] Weigh 2.43 g of copper chloride dihydrate, add 500 g of water to form a copper chloride aqueous solution, and add 1.94 g of 25% concentrated ammonia water dropwise to prepare a copper hydroxide gel. With 20g of NH containing template 4 The β molecular sieve was stirred and mixed at room temperature, filtered, washed, and the filter cake was dried and placed in a muffle furnace. In an air atmosphere, the temperature was raised to 350°C and roasted at 350°C for 4 hours to obtain sample S2a. See the thermogravimetric map Attached figure 1 The S2a curve shows that the organic template is removed cleanly.

[0047] The sample S2a was pulverized into powder in the quartz mill, 100 mL of ammonium acetate aqueous solution with a mass fraction of 10% was added, and the pH was adjusted to about 7.0 with ammonia water. Stir at room temperature for 120-180 minutes, filter, wash, and dry to obtain sample S2.

[0048] Sample S2 was analyzed by X-ray fluorescence method, and the copper con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com