Aluminum ash recycling method

A technology of aluminum ash and secondary aluminum, which is applied to the preparation/separation of alumina/hydroxide and ammonia, which can solve the problems of low recovery rate of aluminum slag treatment, large energy consumption, and large waste, so as to avoid atmospheric dust Effects of pollution, avoidance of pollution, avoidance of air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

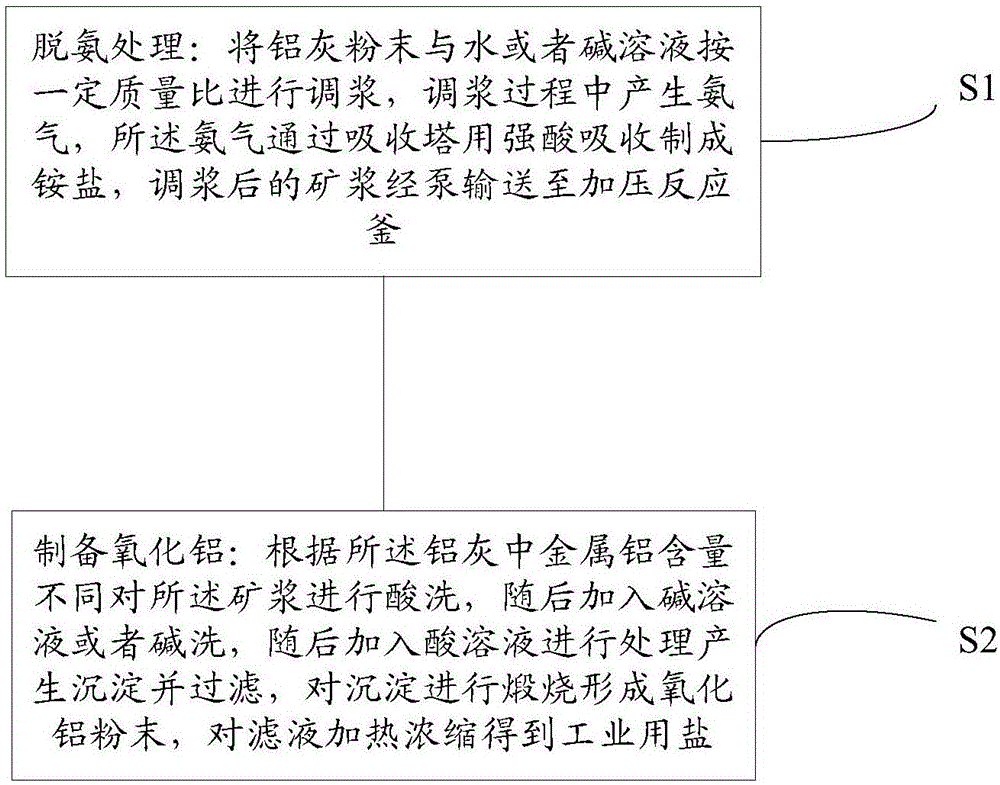

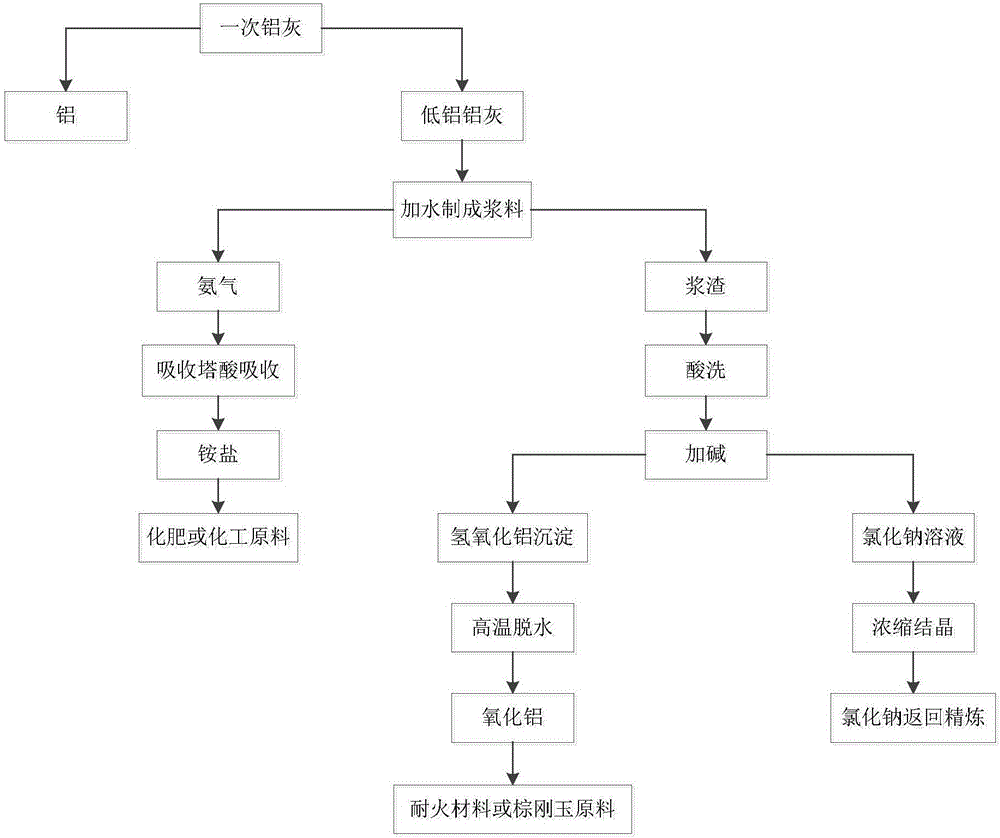

[0032] like figure 2 As shown, the primary aluminum ash is recycled, including steps:

[0033] S1: Separation of aluminum ash and metal aluminum: Grinding and sieving the aluminum ash, the oversieve is metal aluminum flakes, and the undersieve is aluminum ash powder. The metal aluminum flakes can be collected directly or washed with water before being collected. Aluminum ash The powder enters the following deamination step;

[0034] S2: Deamination treatment, the aluminum ash powder and water are mixed in the mixing tank according to the mass ratio of 1:1~1:4, the mixing time is 5~15h, and the temperature is kept at 78~82°C. Ammonia gas, the ammonia gas is absorbed by strong acid through the absorption tower to make ammonium salt, and the slurry after pulping is pumped to the pressurized reaction kettle;

[0035] In the above-mentioned deamination treatment, the aluminum ash powder and water are mixed according to a certain mass ratio, and the slurry is mixed at a certain t...

Embodiment 2

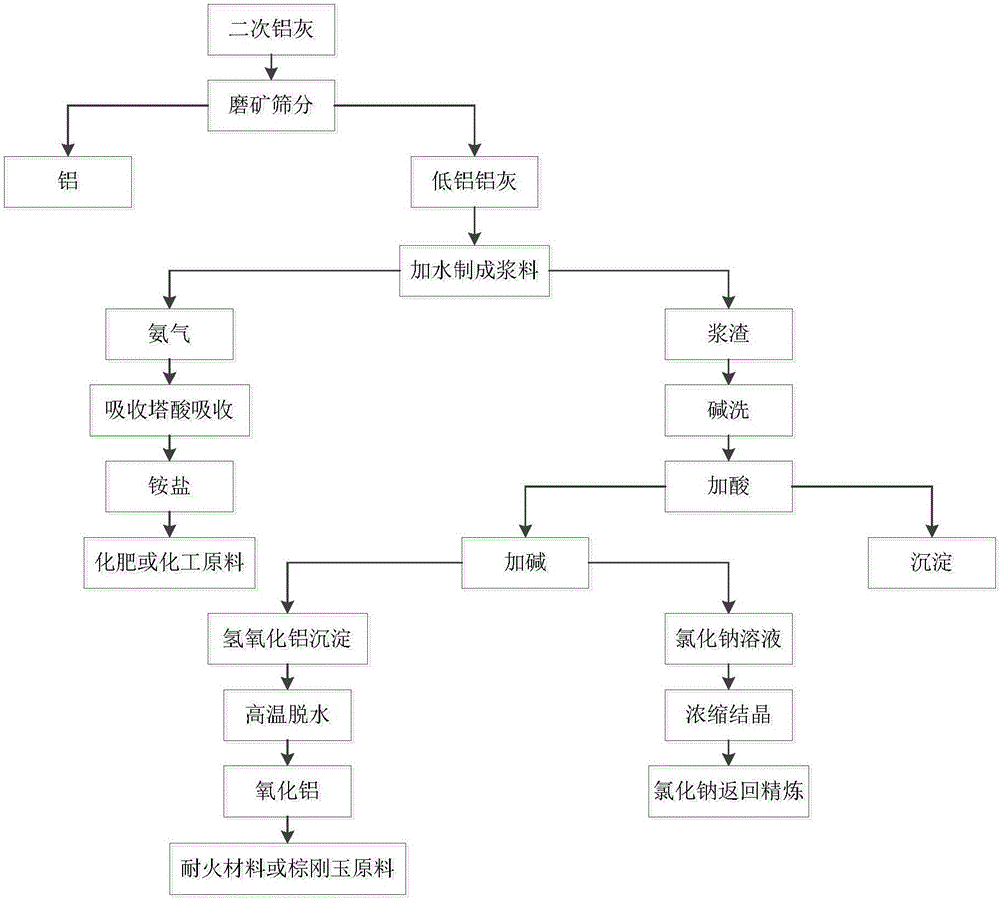

[0042] like image 3 As shown, the secondary aluminum ash is recycled and reused, including steps:

[0043] S1: Separation of aluminum ash and metal aluminum: Grinding and sieving the aluminum ash, the oversieve is metal aluminum flakes, and the undersieve is aluminum ash powder. The metal aluminum flakes can be collected directly or washed with water before being collected. Aluminum ash The powder enters the following deamination step;

[0044] S2: Deamination treatment, mixing aluminum ash powder and water in a mixing tank at a mass ratio of 1:1 to 1:3 for 5 to 10 hours, and keeping the temperature at 68 to 72°C. Ammonia gas, the ammonia gas is absorbed by strong acid through the absorption tower to make ammonium salt, and the slurry after pulping is pumped to the pressurized reaction kettle;

[0045]In the above-mentioned deamination treatment, the aluminum ash powder and water are slurried according to a certain mass ratio, and the slurry is slurried at a certain tempera...

Embodiment 3

[0055] like Figure 4 As shown, when recycling the three-time aluminum ash, it includes: S1: fully mix the three-time aluminum ash and alkali solution and let it stand for 3-5 hours, the ammonia gas generated is absorbed through the absorption tower, and the insoluble impurities are filtered out; The aluminum ash is directly washed three times with alkali, so that alumina, aluminum, etc. are fully dissolved, and ammonia gas is generated during the alkali washing process, which can be absorbed through the absorption tower; the ammonia gas can be made into ammonium salt for recycling, and the reaction equation is as follows as shown,

[0056] al 2 o 3 +2NaOH=2NaAlO 2 +H 2 O;

[0057] 2Al+2NaOH+2H 2 O=2NaAlO 2 +3H 2 ;

[0058] 2AlN+3H 2 O=Al 2 o 3 +2NH 3 ;

[0059] al 2 o 3 +2NaOH=2NaAlO 2 +H 2 O;

[0060] S2: Add equimolar hydrochloric acid, let it stand for a period of time to fully react to form aluminum hydroxide precipitate and filter, calcinate the precip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com