Resourceful treatment and cyclic utilization method of PCB circuit board waste etching liquid

A technology for PCB circuit board and etching waste liquid, which is applied in the field of resource treatment and recycling of PCB circuit board etching waste liquid, can solve the problems that the ammonia nitrogen content is not easy to reach the standard, the operation steps are cumbersome, the steam consumption is large, etc. The effect of energy consumption, simple process and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

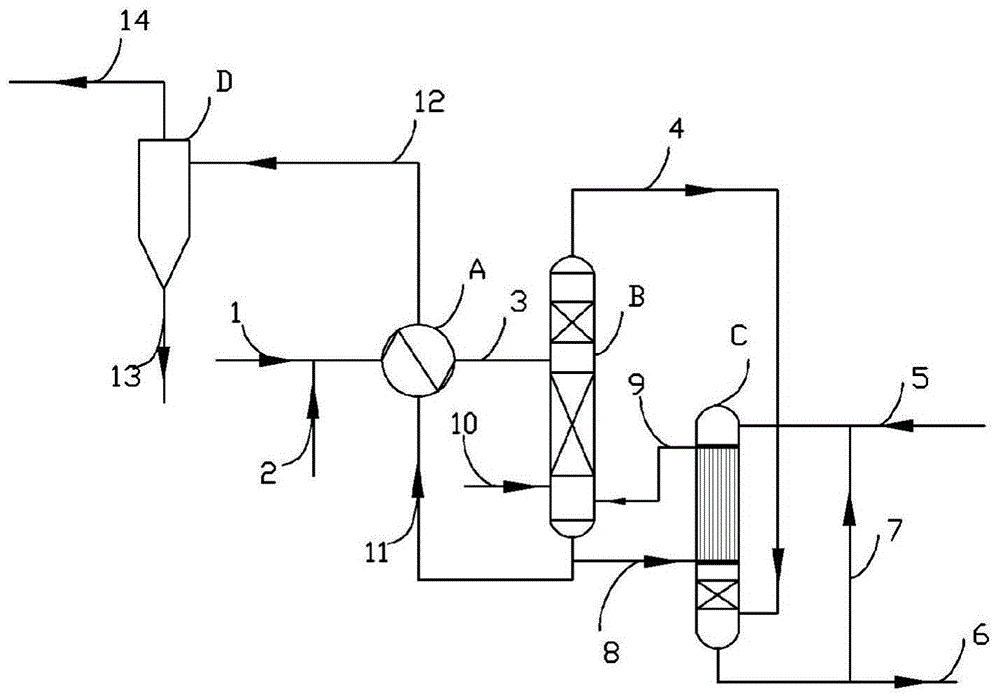

Image

Examples

Embodiment 1

[0043] The water quality of a circuit board etching waste liquid is: ammonia nitrogen concentration 50000mg / L, copper ion concentration 50000mg / L, pH value 9.4. During treatment, adjust the pH of the raw wastewater to 11.5 with 45% sodium hydroxide and then transport it to a reaction deamination tower with 6 theoretical plates. The temperature at the bottom of the tower is 70°C, the temperature at the top of the tower is 70°C, and the gauge pressure is -0.9 Deamination treatment is carried out under 1 atmospheric pressure. The ammonia content (volume percentage of ammonia) in the separated ammonia vapor is 70%. After the ammonia vapor enters the ammonia absorption tower, it is absorbed by concentrated hydrochloric acid into ammonium chloride solution. The reaction of the absorption process The temperature is 150°C, 85% of the generated ammonium chloride is refluxed, and the remaining 15% is collected as a product. After deamination, the high-temperature deamination water is ex...

Embodiment 2

[0045] The water quality of a circuit board etching waste liquid is: ammonia nitrogen concentration 100000mg / L, copper ion concentration 110000mg / L, pH value 9.6. During treatment, adjust the pH of the raw wastewater to 11.5 with 45% sodium hydroxide, and then transport it to a reaction deamination tower with 6 theoretical plates. The temperature at the bottom of the tower is 90°C, the temperature at the top of the tower is 90°C, and the gauge pressure is 0.1 Deamination treatment is carried out under atmospheric pressure. The ammonia content (volume percentage of ammonia) in the separated ammonia vapor is 70%. After entering the ammonia absorption tower, the ammonia vapor is absorbed by concentrated hydrochloric acid into ammonium chloride solution. The reaction temperature of the absorption process is At 175°C, 85% of the generated ammonium chloride was refluxed, and the remaining 15% was collected as a product. After deamination, the high-temperature deamination water is ex...

Embodiment 3

[0047] The water quality of a circuit board etching waste liquid is: ammonia nitrogen concentration 150000mg / L, copper ion concentration 130000mg / L, pH value 9.7. During treatment, adjust the pH of the raw wastewater to 12 with 45% sodium hydroxide and transport it to a reaction deamination tower with 16 theoretical plates. The temperature at the bottom of the tower is 110°C, the temperature at the top of the tower is 100°C, and the gauge pressure is 7 Deamination treatment is carried out under atmospheric pressure. The ammonia content (volume percentage of ammonia) in the separated ammonia vapor is 50%. After the ammonia vapor enters the ammonia absorption tower, it is absorbed by concentrated hydrochloric acid into ammonium chloride solution. The reaction temperature of the absorption process is At 190°C, 75% of the generated ammonium chloride was refluxed, and the remaining 25% was collected as a product. After deamination, the high-temperature deamination water is exchange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com