Method for extracting vanadic anhydride from stone coal vanadium ore

A technology for vanadium pentoxide and stone coal vanadium, which is applied in the field of extracting vanadium pentoxide, can solve the problems of surrounding air and water pollution, high process requirements, and large equipment investment, and achieve high-grade product quality, shorten the process, and adapt to good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

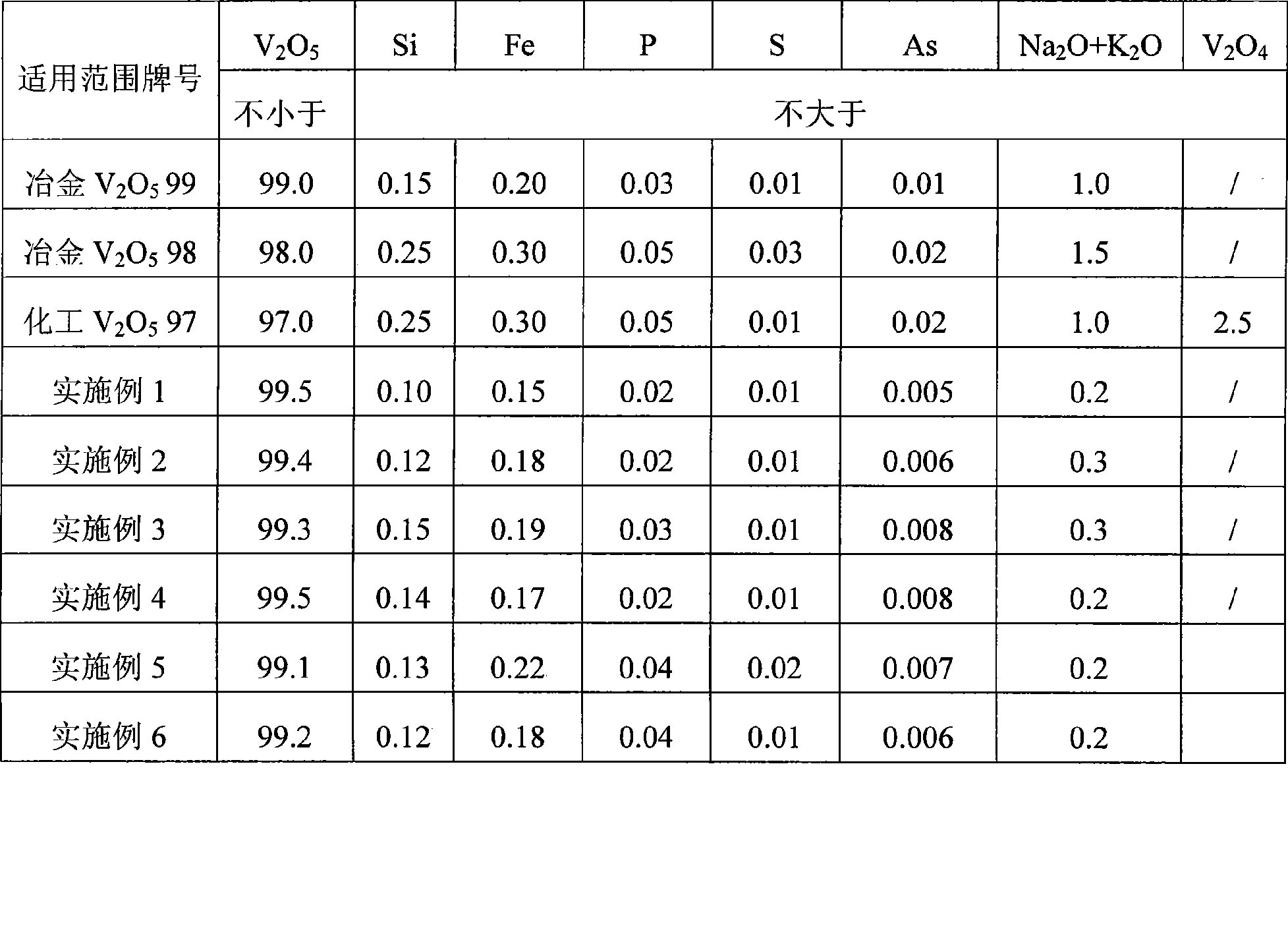

Embodiment 1

[0033] will V 2 o 5 The stone coal vanadium ore with a grade of 1.5% was ground to 60 mesh, weighed 500 g, roasted at 600° C. for 60 min, and cooled naturally after taking it out. Take by weighing again the stone coal vanadium ore 400g after corresponding roasting, drop into in the dilute sulfuric acid of 10% (weight), dilute sulfuric acid consumption is 10% (weight) of stone coal vanadium ore, at 90 ℃ of conditions, insulation 24h, use High-efficiency microporous filter filtration, filtrate with 10% N 235 +5%TBP+85%sulfonated kerosene for 4-stage extraction, 3-stage Na 2 CO 3 Stripping, Na 2 CO 3 The concentration is 50-150g / l, the stripping solution is precipitated with ammonium chloride, and then the pH value is adjusted to 7.5 with sulfuric acid, heated to 85°C and kept for 30 minutes to complete the vanadium precipitation process, filtered with a high-efficiency microporous filter, and heated with a hot Washing solution (pure water). Deamination at 280°C for 1 hour...

Embodiment 2

[0035] will V 2 o 5 The stone coal vanadium ore with a grade of 1.2% was ground to 80 mesh, weighed 500 g, roasted at 700° C. for 90 min, and cooled naturally after taking it out. Take by weighing again the stone coal vanadium ore 400g after corresponding roasting, drop into in the dilute sulfuric acid of 10% (weight), dilute sulfuric acid consumption is 10% (weight) of stone coal vanadium ore, at 90 ℃ of conditions, insulation 24h, use High-efficiency microporous filter filtration, filtrate with 15% N 235 +5%TBP+80%sulfonated kerosene for 4-stage extraction, 3-stage Na 2 CO 3 Stripping, Na 2 CO 3 The concentration of vanadium is 50-150g / l, the stripping solution is precipitated with ammonia water, and then the pH value is adjusted to 8 with sulfuric acid, heated to 85°C and kept for 30 minutes to complete the vanadium precipitation process, filtered with a high-efficiency microporous filter, and washed with hot washing liquid Wash (pure water). Deamination at 280°C for...

Embodiment 3

[0037] will V 2 o 5 The stone coal vanadium ore with a grade of 1.1% was ground to 100 mesh, weighed 1200kg, roasted at 800° C. for 2 hours, and cooled naturally after taking it out. Take by weighing again the stone coal vanadium ore 1000kg after corresponding roasting, drop into in the dilute sulfuric acid of 10% (weight), dilute sulfuric acid consumption is 15% (ml / g) of stone coal vanadium ore, at 90 ℃ of conditions, insulation 24h , filtered with a high-efficiency microporous filter, and the filtrate was filtered with 10% N 235 +5%TBP+85%sulfonated kerosene for 4-stage extraction, 3-stage Na 2 CO 3 Stripping, Na 2 CO 3 The concentration of vanadium is 50-150g / l, the stripping solution is precipitated with ammonia water, and then the pH value is adjusted to 6 with sulfuric acid, heated to 85°C and kept for 30 minutes to complete the process of vanadium precipitation, filtered with a high-efficiency microporous filter, and washed with hot water Liquid washing (pure wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com