Method for preparing biological diesel oil antioxidant additive with biomass microwave auxiliary directional thermal decomposition

An antioxidant additive, microwave-assisted technology, used in fuel additives, chemical instruments and methods, petroleum industry, etc., can solve the problem of high cost of antioxidants, and achieve the effects of reducing separation difficulty, good miscibility, and rich mineral element content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

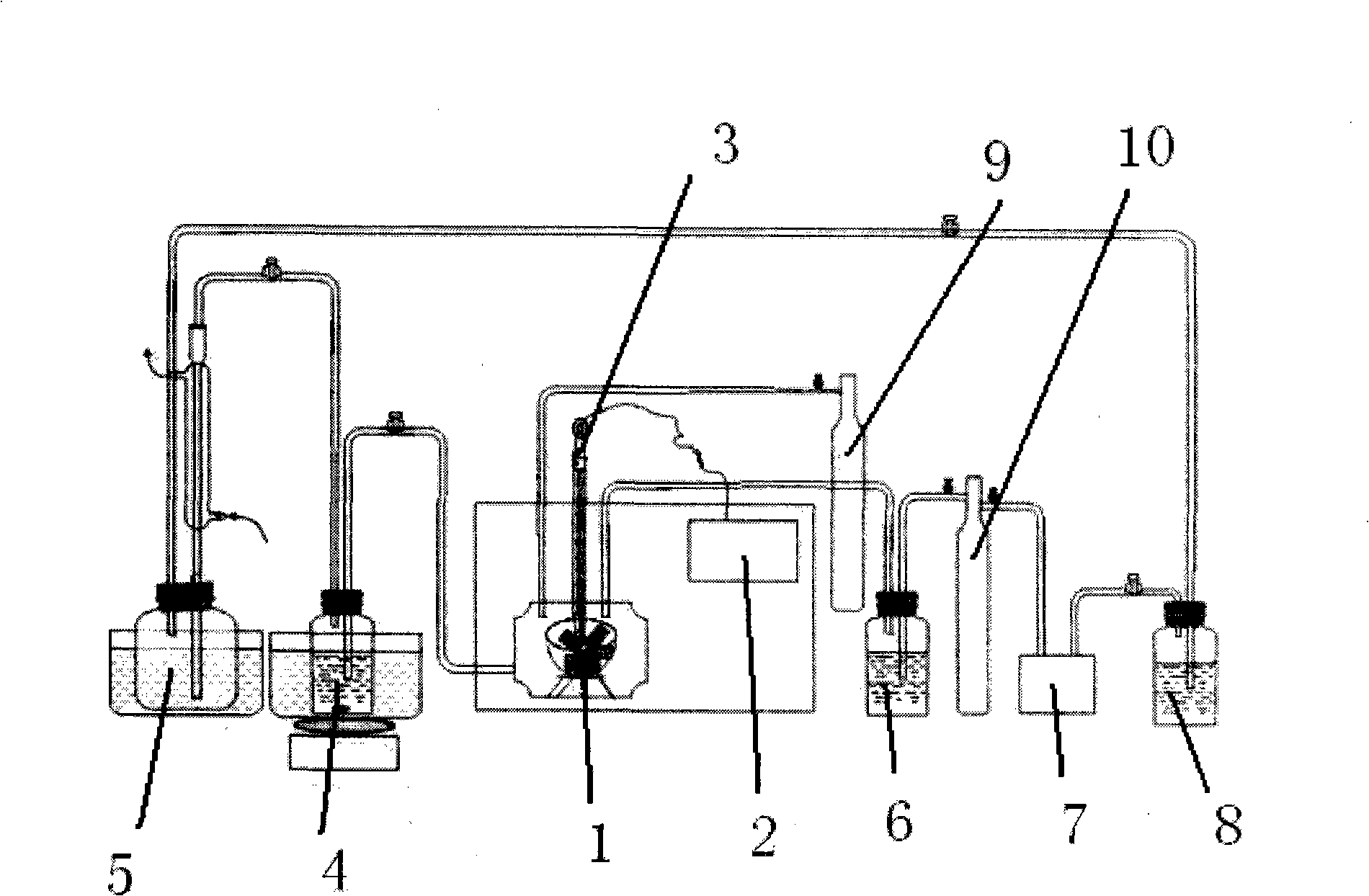

Image

Examples

Embodiment 1

[0012] The Chinese fir bark of 100g is cut off and pulverized, after all passing through 20 mesh screens, with 200g mass fraction, be that the dilute sulfuric acid solution of 0.5% is soaked 12 hours and drain gravity water, then it is sent into special-purpose microwave pyrolysis device ( Temporarily do not add ionic liquid medium), confirm the airtightness of the system, and empty the air in the system with nitrogen; control the microwave pyrolysis temperature ≤ 120 ℃, keep it for 20 minutes, collect the acetic acid, formic acid and methanol that occur, and when the liquid at the condensation nozzle The drop rate is less than 1d / min, take out about 103.5g of the collected liquid (containing about 3g of acetic acid, about 1g of methanol, and about 0.1g of formic acid); use nitrogen to empty the air in the system, raise the microwave pyrolysis temperature to ≤150°C, and keep 8min, collect furfural and light bio-oil, when the dripping speed of the liquid at the condensation nozz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com