Production process of antioxidant 2,6-di-tert-butyl-4-methy phenol

A technology of di-tert-butyl and methyl phenol, which is applied in the direction of organic chemistry, can solve the problems of product shelf life impact, product unrecoverable, product yield reduction, etc., and achieve the effect of saving heat, preventing waste of raw materials, and complete reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

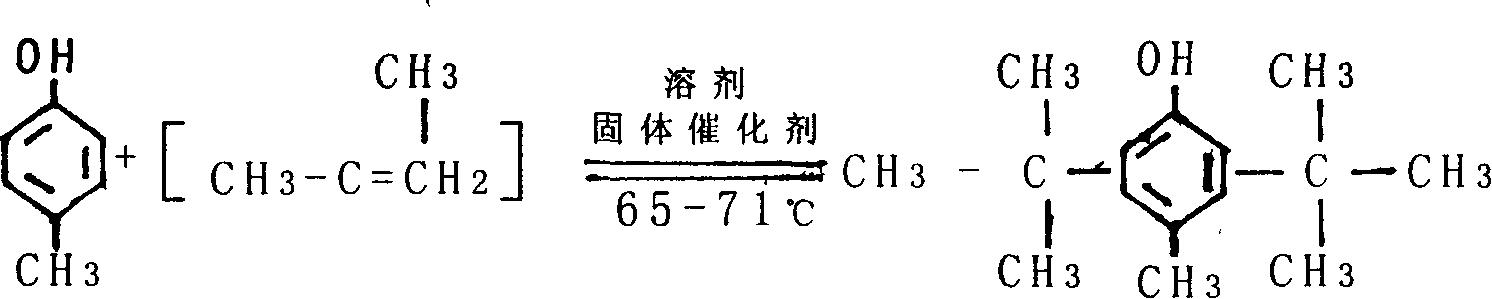

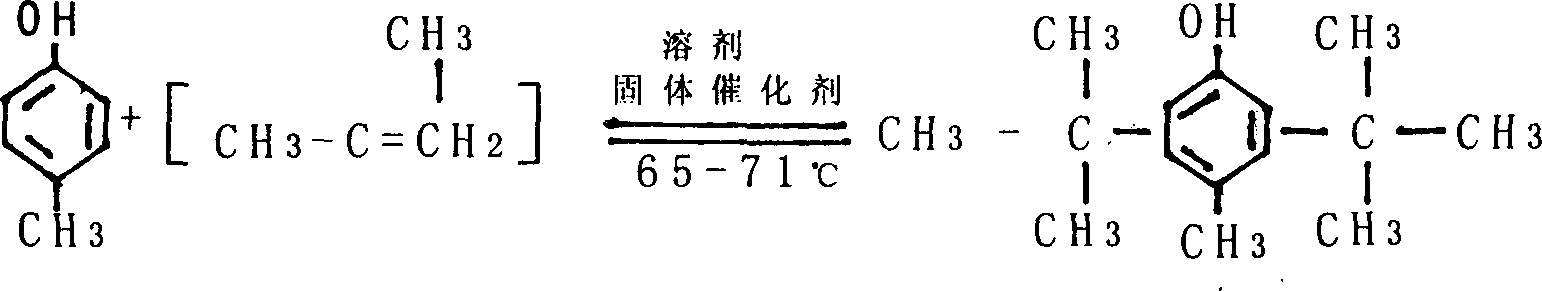

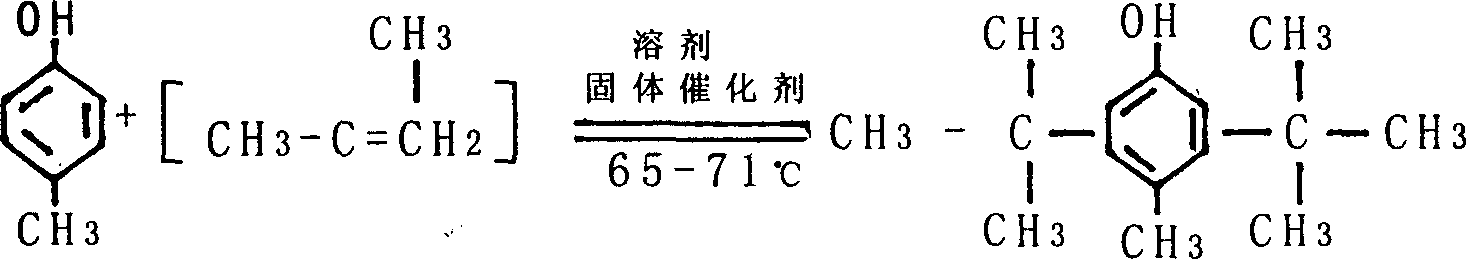

[0016] 1. First carry out the alkylation reaction, and the solvent, p-cresol, isobutylene and solid catalyst that can be compatible with 2,6-di-tert-butyl-4-methylphenol are mixed according to the weight ratio of 0.6~1:1:1.030~ 1.045:0.016~0.075 material, the solvent is edible soybean oil or lubricating oil base oil or sesame oil or liquid paraffin or mono-tert-butylphenol or isobutylene dimer or low-molecular polyisobutene or mono-tert-butyltetracresol Or 2,6-di-tert-butylphenol. The solid catalyst is a mixture of aluminosilicate and concentrated sulfuric acid, wherein the weight ratio of aluminosilicate and concentrated sulfuric acid is 1:0.01 to 1:0.03, the solid catalyst is added to the alkylation tank, and then p-formaldehyde Phenol and isobutylene react at 65°C to 71°C, and the reaction formula is:

[0017]

[0018] 2. Initial crystallization, after the reaction is complete, guide the material into the crystallization tank, and leave the solid catalyst in the alkylat...

Embodiment 2

[0022] 1. First carry out the alkylation reaction, and take the solvent, p-cresol, isobutylene and solid catalyst compatible with 2,6-di-tert-butyl-4-methylphenol according to the weight ratio of 0.6:1:1.03:0.016 The solvent is edible soybean oil or lubricating oil base oil or sesame oil or liquid paraffin or mono-tert-butylphenol or isobutylene dimer or low-molecular polyisobutene, and the solid catalyst is a mixture of aluminosilicate and concentrated sulfuric acid. The weight ratio of the aluminosilicate to the concentrated sulfuric acid is 1:0.01, the solid catalyst is added into the alkylation tank, p-cresol and isobutylene are added, and the reaction is carried out at 65°C to 71°C.

[0023] 2. Initial crystallization, after the reaction is complete, guide the material into the crystallization tank, and leave the solid catalyst in the alkylation tank for the next use, then slowly lower the temperature to 25°C to completely fold out the crystals, and separate the crystals w...

Embodiment 3

[0027] 1. First carry out the alkylation reaction, and take the solvent, p-cresol, isobutylene and solid catalyst compatible with 2,6-di-tert-butyl-4-methylphenol according to the weight ratio of 1:1:1.045:0.075 The solvent is edible soybean oil or lubricating oil base oil or sesame oil or liquid paraffin or mono-tert-butylphenol or isobutylene dimer or low-molecular polyisobutene or mono-tert-butyltetracresol or 2,6-di tert-butylphenol, the solid catalyst is a mixture of aluminosilicate and concentrated sulfuric acid, wherein the weight ratio of aluminosilicate and concentrated sulfuric acid is 1: 0.03, the solid catalyst is added in the alkylation tank, and then the Cresol and isobutylene react at 65°C to 71°C.

[0028] 2. Initial crystallization, after the reaction is complete, guide the material into the crystallization tank, and leave the solid catalyst in the alkylation tank for the next use, then slowly lower the temperature to 25°C to completely fold out the crystals, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com