Coal chemical wastewater pretreatment process and device

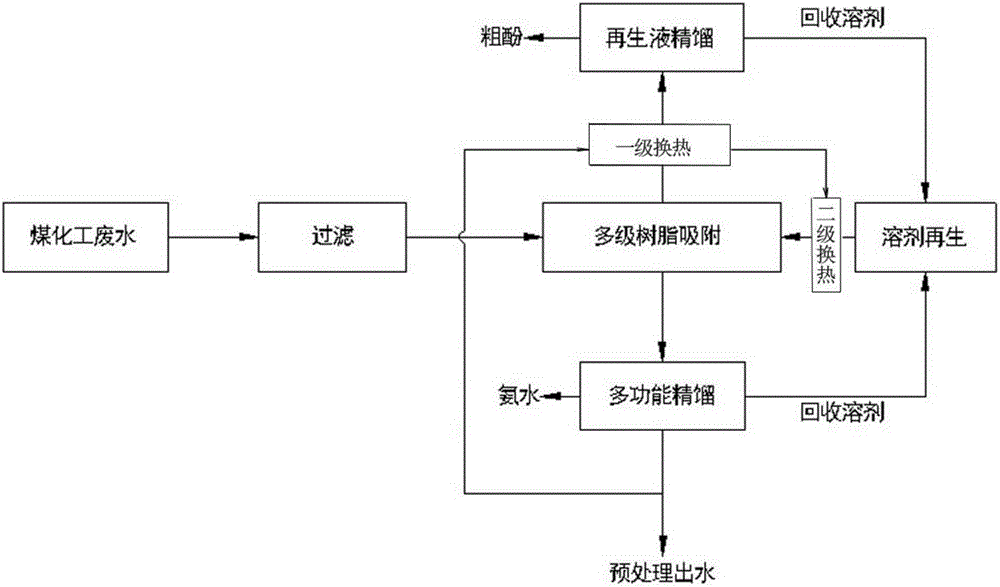

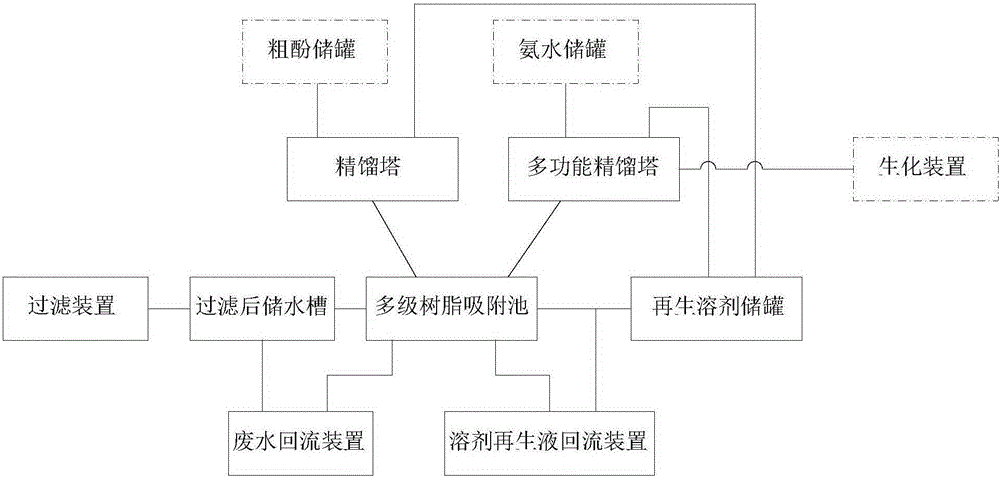

A technology of coal chemical wastewater and pretreatment device, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, water pollutants, etc., can solve the problem of low value of recycled products, large loss of extractant and large equipment investment. and other problems, to achieve the effect of being conducive to ecological environmental protection, improving biodegradability, and reducing investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

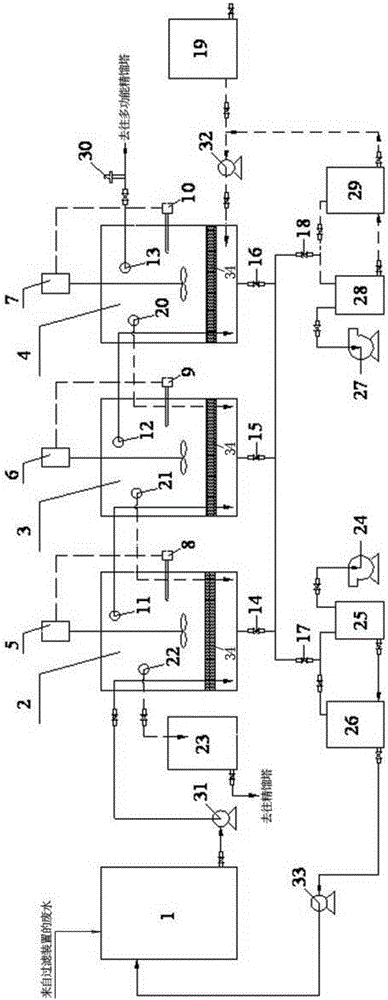

[0057] See image 3 , is a schematic diagram of the device structure of the resin adsorption and solvent regeneration process in this embodiment. In this embodiment, the resin adsorption adopts three-stage resin adsorption pools connected in sequence. The waste water inlet in the first-stage resin adsorption pool 2 is connected to the filtered water storage tank 1 through the pipeline and the waste water lifting pump 31, and the waste water overflow port passes through the waste water overflow. Pipe one 11 is connected to the waste water inlet of the secondary resin adsorption pool 3, and the solvent regeneration liquid inlet is connected to the solvent regeneration liquid overflow port of the secondary resin adsorption pool 3 through the solvent regeneration liquid overflow pipe two 21, and the solvent regeneration liquid overflows The pipe three 22 is connected to the rectification tower through the regeneration liquid storage tank 23 and pipelines; the first-stage resin ads...

Embodiment 2

[0073] The device adopted in this embodiment is the same as that of Embodiment 1, and the waste water pretreatment process is:

[0074] During the resin adsorption process, the raw water COD of coal chemical industry wastewater is 21370mg / L, and the volatile phenol is 3852mg / L. Under the condition of pH=8.7, the treatment capacity is 10BV / h (BV is the resin volume). After filtration and resin adsorption, COD is 2498mg / L, removal rate is 88%, volatile phenol is 262mg / L, removal rate is 93%.

[0075] The resin regeneration process is basically the same as in Example 1.

Embodiment 3

[0077] The device adopted in this embodiment is the same as that of Embodiment 1, and the waste water pretreatment process is:

[0078] In resin adsorption, the raw water COD of coal chemical industry wastewater is 21370mg / L, and the volatile phenol is 3852mg / L. Under the condition of pH=3, the treatment capacity is 15BV / h (BV is the resin volume). After filtration and resin adsorption, the COD It is 2675mg / L, and the removal rate is 87.4%, and the volatile phenol is 295mg / L, and the removal rate is 92.3%.

[0079] The resin regeneration process is basically the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com