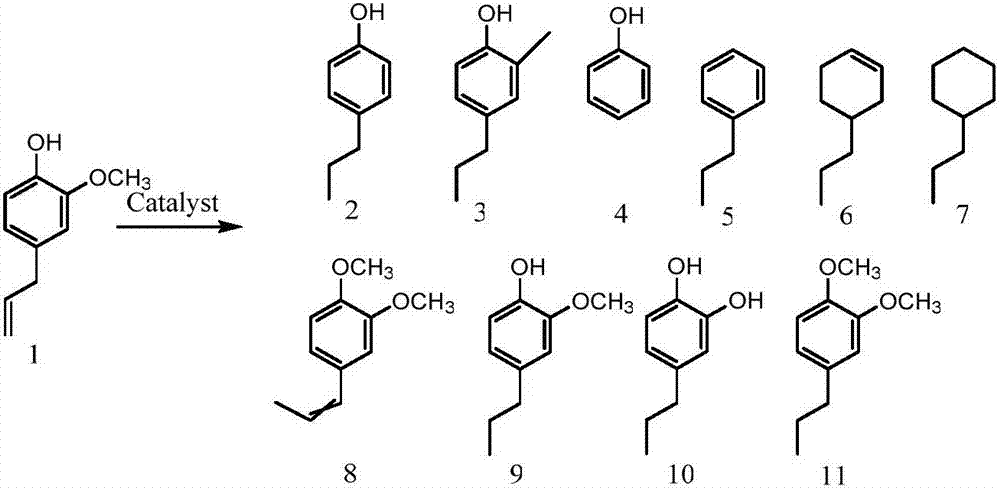

Combined alkaline iron-molybdenum sulfide catalyst, preparation method of catalyst and application of catalyst to aromatic phenol and ether conversion

A catalyst and composite technology, applied in the preparation of organic compounds, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve the effect of improving activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

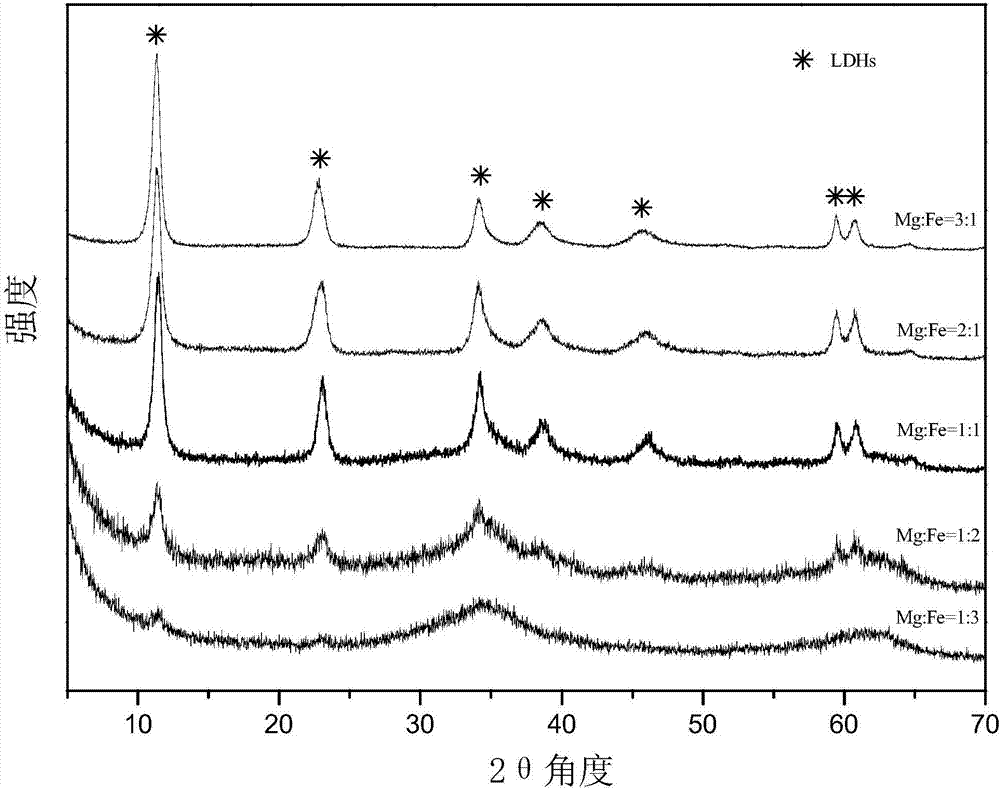

[0028] This example illustrates the preparation of hydrotalcites with different ratios in the present invention, taking Mg:Fe=3:1 as an example

[0029] (a) Weigh 21.77g (0.09mol) of magnesium nitrate, dissolve 12.12g (0.03mol) of ferric nitrate in 250ml of deionized water, stir until clear; weigh 9.6g (0.24mol) of sodium hydroxide, 6.36g (0.06mol) ) Sodium carbonate is dissolved in 250mol deionized water, stirred until clarification;

[0030] (b) Drop the two solutions into 500ml deionized water at the same time, stir in a 70°C water bath, and control the titration speed to ensure that the pH is between 9-10; after the titration, continue to stir for 120 minutes, and then transfer to the oven, The crystallization temperature was set at 70° C., and the crystallization time was 12 hours.

[0031] (c) After crystallization, filter and wash the precipitate with deionized water until the pH is neutral, and dry the obtained precipitate at 70°C for 12 hours to obtain Mg with an ato...

Embodiment 2

[0035] This example illustrates the preparation of hydrotalcite-based composite oxides in the present invention

[0036] The different proportions of hydrotalcites prepared in Example 1 were placed in a muffle furnace, the temperature rise program was set to 5-20K / min, and it was raised to 400°C to obtain the different proportions of Mg at this temperature x Fe y oxide.

[0037] Change the roasting temperature between 350-500°C to ensure that CO 3 2‐ removal while maintaining the recoverability of its structure.

Embodiment 3

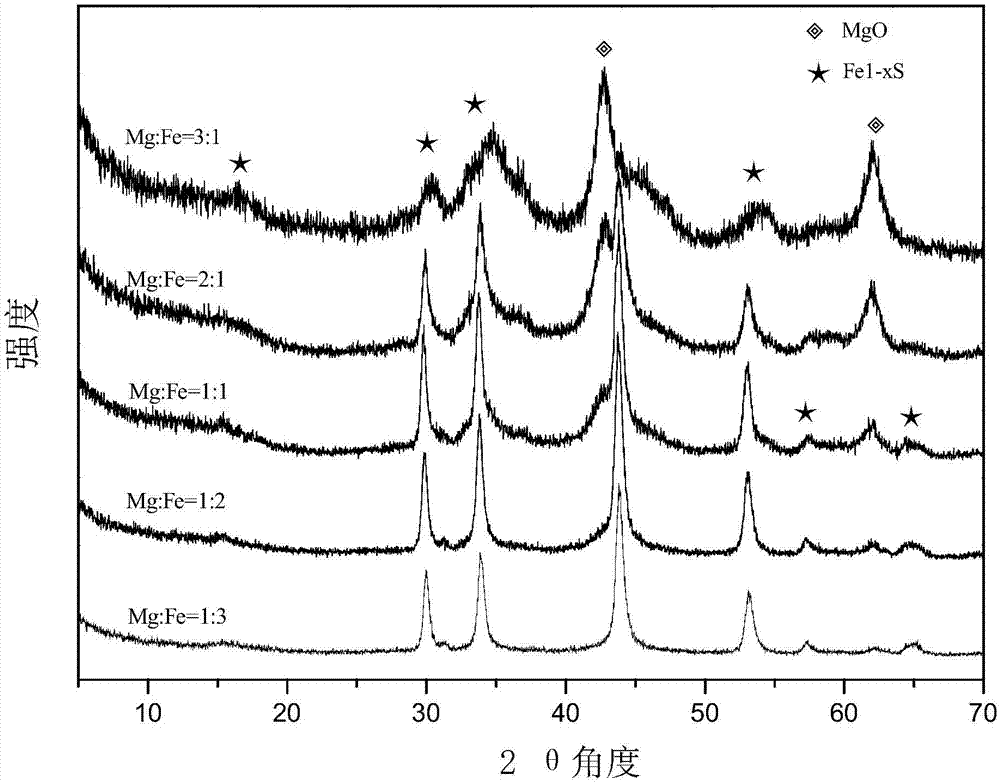

[0039] The present embodiment illustrates the preparation of composite sulfide catalyst in the present invention

[0040] (a) Weigh 2.0g of ammonium heptamolybdate and dissolve it in 16mol deionized water, stir to form a clear solution, then weigh 1.0g of Mg obtained by calcining at 400°C in Example 3x Fe y Add the oxide to the solution, seal the mouth of the beaker with parafilm, ion exchange at room temperature for 12 hours, wash and dry to obtain MgxFey-MoO 4 2- precursor; then in 10% H 2 S / H 2 Sulphurization in a mixed gas, the sulphurization temperature is 400 ° C, and the time is 4 hours, and the alkali metal composite iron molybdenum sulfide catalyst MgxFey-Mo-S is finally obtained. According to different proportions, respectively recorded as Mg 3 Fe 1 Mo-S, Mg 2 Fe 1 Mo-S, Mg 1 Fe 1 Mo-S, Mg 1 Fe 2 Mo-S, Mg 1 Fe 3 Mo-S.

[0041] The XRD of the catalyst prepared under this condition is shown in figure 2 As shown, MoS was not observed in the end 2 diffra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com