Method of extracting phenolic compound from coal liquefied oil or coal tar

A technology of phenolic compounds and coal liquefied oil, applied in the field of coal chemical industry, can solve the problems of huge investment, limited extraction rate of phenol, and low purity of phenol products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

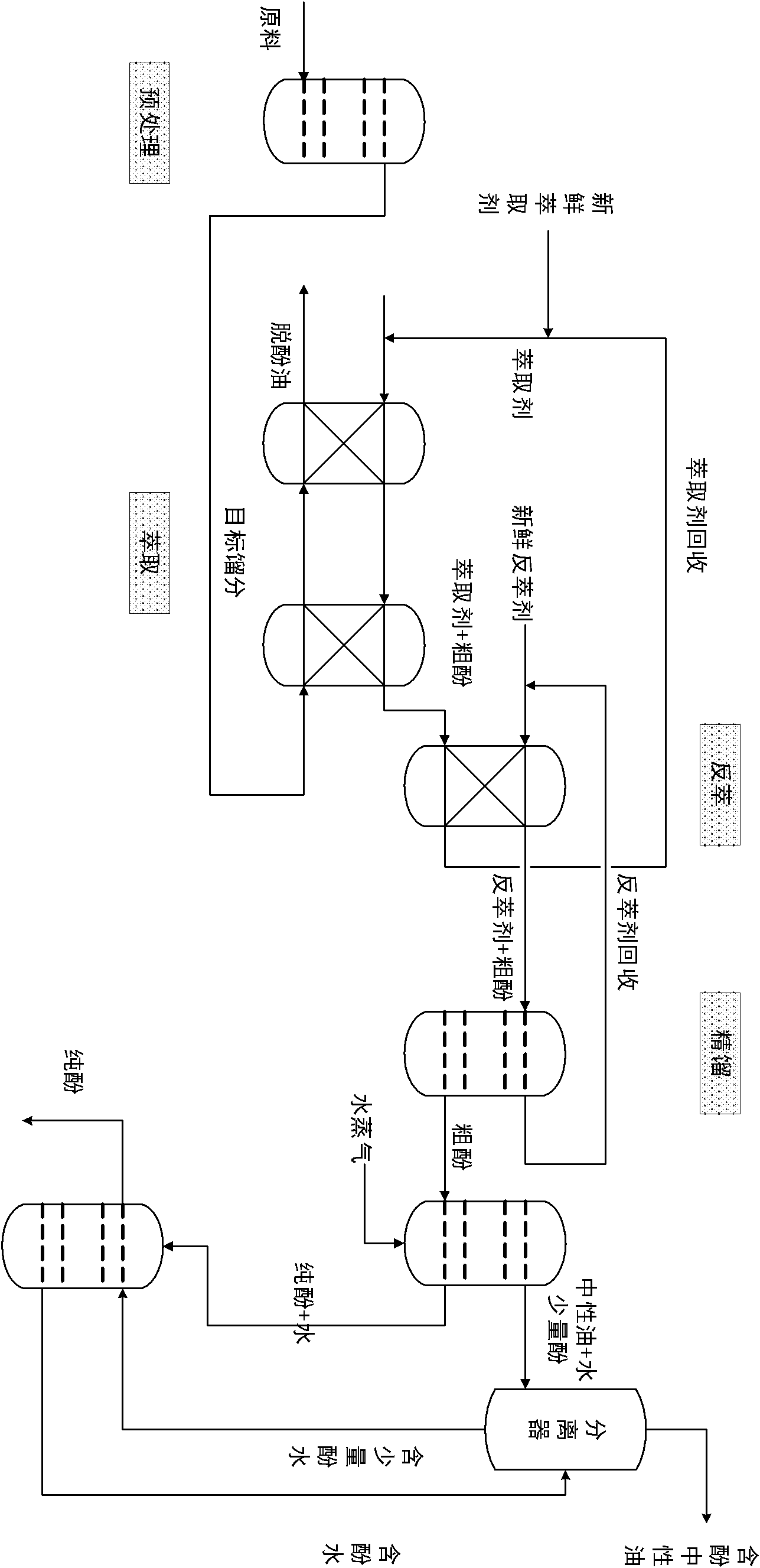

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1, extract phenolic compound from coal direct liquefaction oil

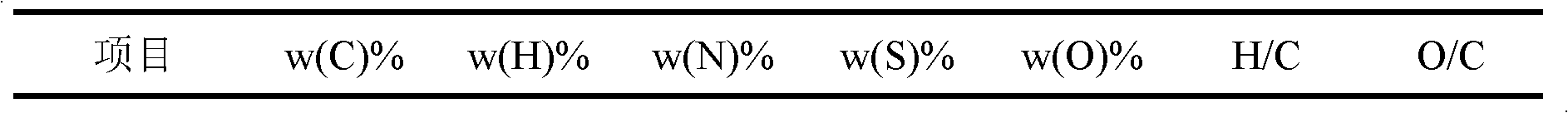

[0029] The raw material to be treated is taken from the liquid product obtained on the 0.1t / d coal direct liquefaction continuous test device, and its elemental analysis results are shown in Table 1.

[0030] Table 1 Elemental analysis results of direct coal liquefaction oil

[0031]

[0032]

[0033] The main phenolic compounds were qualitatively and quantitatively analyzed by means of GC-MS chromatography-mass spectrometry, and their specific compositions are shown in Table 2.

[0034] Table 2 Analysis results of phenolic compounds in direct coal liquefaction oil

[0035]

[0036] The content of phenolic compounds in coal liquefied oil is about 14.5% (IBP~350°C). After the first step of distillation, the target fraction of 160~230°C is cut. This fraction accounts for about 22% of the total raw materials, and phenol Phenolic compounds account for about 56%, of which the lower phenols, ...

Embodiment 2

[0039] Embodiment 2, continuous device extracts phenolic compounds from medium and low temperature coal tar

[0040] The raw material is taken from a typical medium-low temperature coal tar produced by a coal chemical enterprise in the west. It has been measured that the water content is about 15%. Atmospheric distillation cuts a fraction at 150-210°C, which accounts for about 18% of the overall raw material. It is measured that the content of phenolic compounds is as high as more than 80%.

[0041] Gas chromatography quantitative analysis was carried out on this fraction section, and the specific results are shown in Table 3.

[0042] Analysis results of phenolic compounds in low temperature coal tar in Table 3

[0043]

[0044]

[0045] The operation process of the continuous device has been described in detail in the above summary of the invention, and the main operating data are listed in Table 4 below.

[0046] Table 4 The main operating data of the continuous pro...

Embodiment 3

[0049] Embodiment 3, extract phenolic compound from medium temperature coal tar

[0050] The raw material is obtained from a semi-coke production enterprise in the Inner Mongolia Autonomous Region. The water content of medium-temperature coal tar is about 5%. It is measured that the content of phenolic compounds reaches more than 57%.

[0051] Carry out gas chromatography quantitative analysis to this cut section, the results are as shown in table 4:

[0052] Table 4 Analysis results of phenolic compounds in medium temperature coal tar

[0053]

[0054]

[0055] The content of phenolic compounds in this fraction is relatively high. The target fraction is extracted by two-stage countercurrent and centrifuged. The mass ratio of ethylene glycol to fraction is 10:1, the average residence time is 50min, and the temperature is about 20°C. After extraction, the extraction rate of phenol can reach 75%, and the entrainment of neutral oil accounts for about 6.2% of the whole ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com