High-concentration phenol-ammonia sewage treatment method

A sewage treatment method and high-concentration technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of restricting technology promotion, treatment benefit discount, low recovery rate, etc. , to achieve the effect of low solubility, low market price and small loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

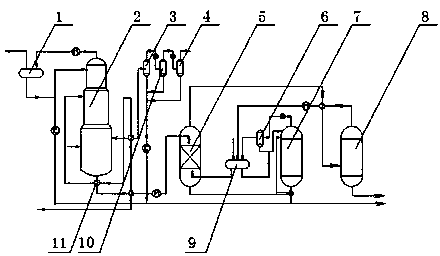

Embodiment 1

[0036] Applying the above-mentioned device for treating wastewater containing phenol and ammonia, the total phenol content of the wastewater is 17520mg / L, free ammonia 1428 mg / L, fixed ammonia 1598 mg / L, carbon dioxide 1532mg / L, pH value 8.54, water temperature 60℃, flow rate 130 tons / Hour, press figure 1 The flow shown is processed. The hot and cold feed ratio of sewage stripping tower 2 is 0.3:1, the top temperature is 61.5℃, the top pressure is 0.62MPa, the bottom temperature is 161℃, the bottom pressure is 0.648MPa, and the mass percentage concentration is 20% caustic soda aqueous solution flow It is 536.9Kg / hr, the temperature of sideline production is 146℃, and the pressure is 0.62MPa. The operating pressure of the three-stage condenser and the one-stage condenser 3 is 0.55 MPa. The operating temperature is 135°C, the operating pressure of the two-stage partial condenser 10 is 0.45 MPa, the operating temperature is 115°C, the operating pressure of the three-stage conde...

Embodiment 2

[0038] Applying the above device for treating phenol-containing wastewater, the total phenol content of wastewater is 16520mg / L, free ammonia 4015 mg / L, fixed ammonia 2354mg / L, carbon dioxide 5420mg / L, pH value 9.23, water temperature 75°C, flow rate 90 tons / hour ,press figure 1 The flow shown is processed. Sewage stripping tower 2 hot and cold feed is 0.7:1, the top temperature is 59℃, the top pressure is 0.60MPa, the bottom temperature is 162℃, the bottom pressure is 0.63MPa, the mass percentage is 18% caustic soda aqueous solution flow rate 430.5Kg / hr, the temperature of sideline extraction is 145℃, and the pressure is 0.59MPa. The operating pressure of the three-stage decondenser 3 is 0.58MPa and the operating temperature is 140°C. The operating pressure of the two-stage condenser 10 is 0.47MPa and the operating temperature is 120°C. The operating pressure is 0.37MPa and the operating temperature is 50°C. The extraction tower 5 adopts a packed tower, the solvent-sewage ...

Embodiment 3

[0040] Applying the above device for treating phenol-containing wastewater, the total phenol content of wastewater is 6520mg / L, free ammonia is 3015 mg / L, fixed ammonia is 2354mg / L, carbon dioxide is 6420mg / L, pH is 9.26, water temperature is 70℃, flow rate is 90 tons / hour ,press figure 1 The flow shown is processed. Sewage stripping tower 2 hot and cold feed is 1.1:1, the top temperature is 85℃, the top pressure is 0.7MPa, the bottom temperature is 180℃, the bottom pressure is 0.75MPa, and the mass percentage is 20% caustic soda aqueous solution flow rate 380.5Kg / hr, the temperature of sideline extraction is 145℃, and the pressure is 0.59MPa. The operating pressure of the three-stage condensing unit 3 is 0.6 MPa, the operating temperature is 155°C, the operating pressure of the two-stage condenser 10 is 0.5 MPa, and the operating temperature is 125°C, and the operating temperature of the three-stage condenser 4 is The operating pressure is 0.39MPa and the operating temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com