Method for synthesizing methyl isobutyl ketone from acetone through one-step method

A technology of methyl isobutyl ketone and acetone, applied in chemical instruments and methods, preparation of organic compounds, preparation of carbon-based compounds, etc., can solve the problem of low acetone conversion rate and MIBK selectivity, high reaction temperature and low conversion rate And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Take a certain amount of γ-Al 2 o 3 Baking at 500°C for 4 hours. Take 100g of roasted γ-Al 2 o 3 , immerse in 100ml of 0.0005g / mL lanthanum nitrate solution, let stand at a constant temperature of 30°C for 12 hours, dry at a constant temperature of 120°C for 12 hours, and bake at a constant temperature of 400°C for 4 hours. After cooling to room temperature, impregnate an equal volume of palladium chloride solution at 30°C for 2.0 hours, filter, dry at 120°C for 6 hours, bake at 400°C for 4 hours, and impregnate 0.05% Pd. The catalyst is designated as PL-1.

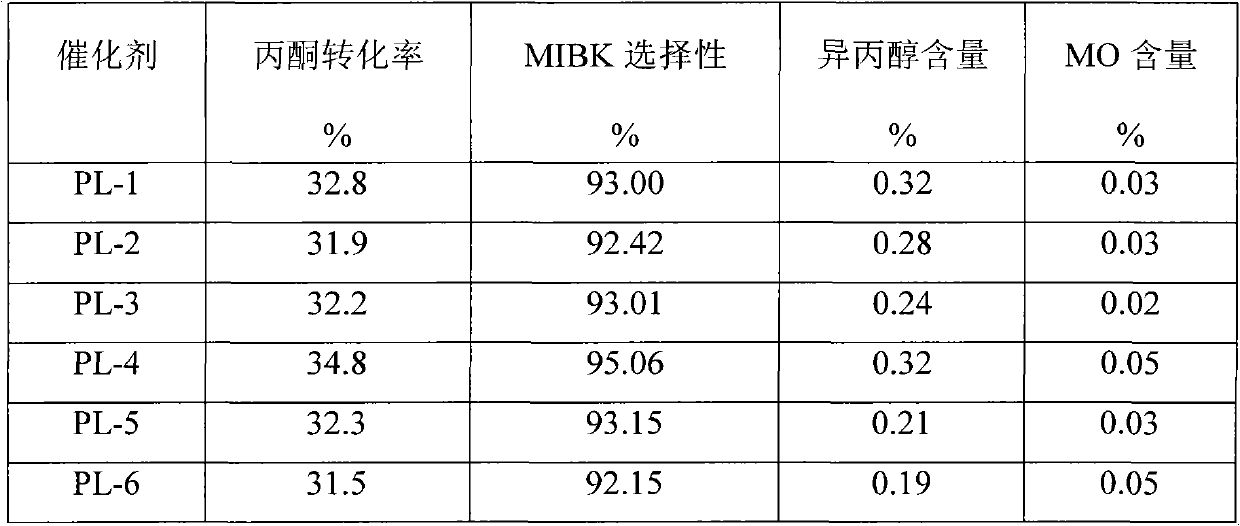

[0018] The catalytic reaction is carried out in a trickle bed reactor, the catalyst is filled with 80ml, the pressure is 3.0MPa, the temperature is 130°C, and the liquid space velocity is 1.0h -1 , the ratio of hydrogen to ketone is 2, acetone and hydrogen pass through the catalyst bed from top to bottom, the product is collected after being cooled by a cold trap, and the product is analyzed by capillary gas c...

Embodiment 2

[0020] Get the Al after roasting among the embodiment 1 2 o 3 100g, soak in 100ml 0.0008g / mL lanthanum nitrate solution, let stand at 30°C for 12 hours, dry at 120°C for 12 hours, and bake at 450°C for 4 hours. After cooling to room temperature, an equal volume of PdCl was impregnated 2 , immersion temperature 40°C, immersion time 2.0 hours, filter, 120°C constant temperature drying for 6 hours, 400°C calcination, constant temperature 4hr, Pd impregnation amount 0.05%. The catalyst is designated as PL-2. The reaction results are shown in Table 1

Embodiment 3

[0022] Get the Al after roasting among the embodiment 1 2 o 3 100g, immerse in 100ml 0.001g / Ml lanthanum nitrate solution, let stand at 40°C for 12 hours, dry at 120°C for 6 hours, and bake at 450°C for 4 hours. After cooling to room temperature, an equal volume of PdCl was impregnated 2 , immersion temperature 40°C, immersion time 3.0 hours, filter, 120°C constant temperature drying for 6 hours, 400°C calcination, constant temperature 4 hours, Pd impregnation amount 0.08%. The catalyst is designated as PL-3. The reaction results are shown in Table 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com