Method for synthesizing methyl isobutyl ketone from acetone through one-step method

A technology of methyl isobutyl ketone and acetone, applied in chemical instruments and methods, preparation of organic compounds, carbon-based compounds, etc., can solve high reaction temperature, low conversion rate of acetone, low selectivity of MIBK, and low conversion rate and other issues, to achieve the effect of low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Take a certain amount of γ-Al 2 o 3 Baking at 500°C for 4 hours. Take 100g of roasted γ-Al 2 o 3 , immerse in 100ml of 0.0005g / mL lanthanum nitrate solution, let stand at a constant temperature of 30°C for 12 hours, dry at a constant temperature of 120°C for 12 hours, and bake at a constant temperature of 400°C for 4 hours. After cooling to room temperature, impregnate an equal volume of palladium chloride solution at 30°C for 2.0 hours, filter, dry at 120°C for 6 hours, bake at 400°C for 4 hours, and impregnate 0.05% Pd. The catalyst is designated as PL-1.

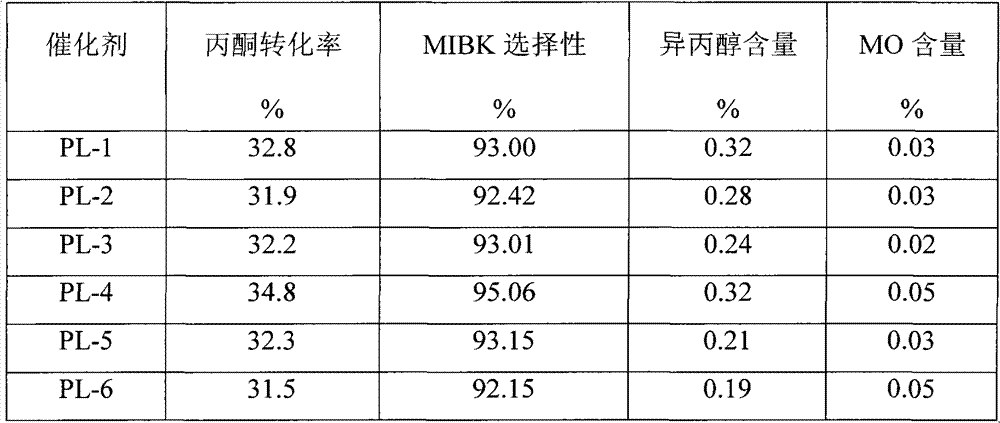

[0018] The catalytic reaction is carried out in a trickle bed reactor, the catalyst is filled with 80ml, the pressure is 3.0MPa, the temperature is 130°C, and the liquid space velocity is 1.0h -1 , the ratio of hydrogen to ketone is 2, acetone and hydrogen pass through the catalyst bed from top to bottom, the product is collected after being cooled by a cold trap, and the product is analyzed by capillary gas c...

Embodiment 2

[0020] Get the Al after roasting among the embodiment 1 2 o 3 100g, soak in 100ml 0.0008g / mL lanthanum nitrate solution, let stand at 30°C for 12 hours, dry at 120°C for 12 hours, and bake at 450°C for 4 hours. After cooling to room temperature, an equal volume of PdCl was impregnated 2 , immersion temperature 40°C, immersion time 2.0 hours, filter, 120°C constant temperature drying for 6 hours, 400°C calcination, constant temperature 4hr, Pd impregnation amount 0.05%. The catalyst is designated as PL-2. The reaction results are shown in Table 1

Embodiment 3

[0022] Get the Al after roasting among the embodiment 1 2 o 3 100g, immerse in 100ml 0.001g / Ml lanthanum nitrate solution, let stand at 40°C for 12 hours, dry at 120°C for 6 hours, and bake at 450°C for 4 hours. After cooling to room temperature, an equal volume of PdCl was impregnated 2 , immersion temperature 40°C, immersion time 3.0 hours, filter, 120°C constant temperature drying for 6 hours, 400°C calcination, constant temperature 4 hours, Pd impregnation amount 0.08%. The catalyst is designated as PL-3. The reaction results are shown in Table 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com