Catalyst for preparing isophorone using condensation of acetone and preparation method thereof

A technology for isophorone and catalyst, which is applied in the field of isophorone condensation catalyst for acetone and its preparation, can solve the problems of low yield and the like, and achieve the effects of easy separation, reduced requirements and fewer types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

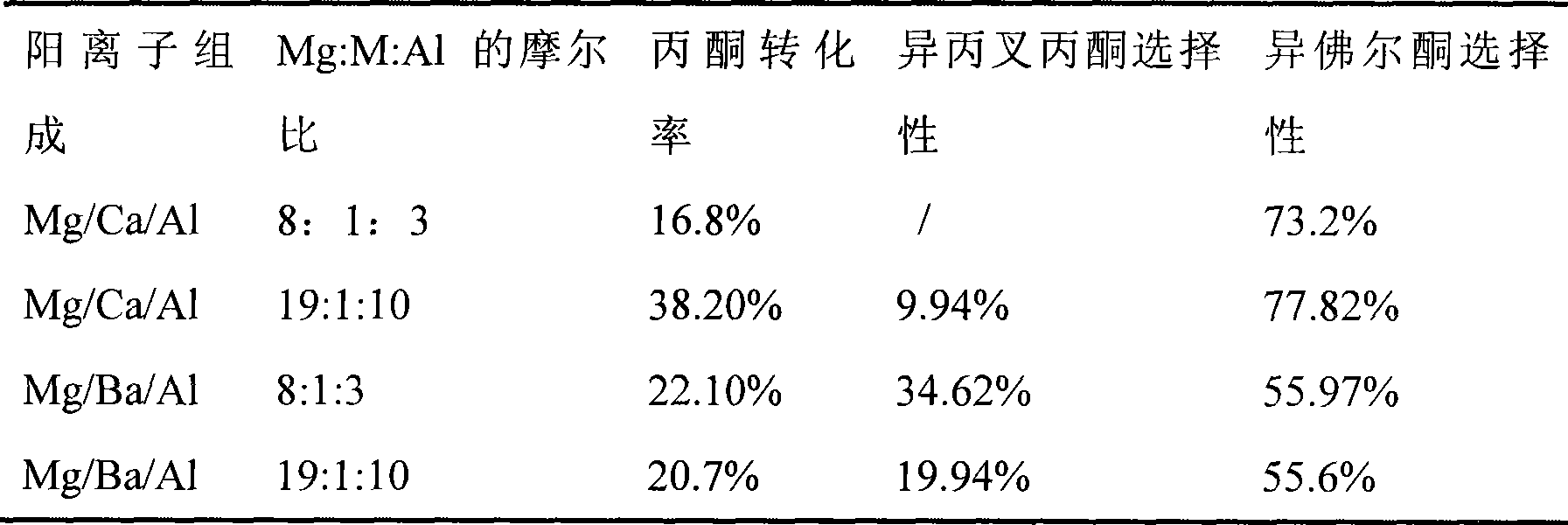

Embodiment 1

[0017] Prepare salt solution with nitrate in molar ratio Mg:Ca:Al=8:1:3, and prepare stoichiometric NaOH and 25% Na 2 CO 3 composed alkaline solution. Add the two solutions side-by-side to a small amount of distilled water at 80°C under mechanical stirring, and adjust the rate of addition to maintain the pH value between 8-10. After the dropwise addition, keep stirring mechanically at 80°C for 24h, filter after cooling, and wash with a large amount of water. The filter cake was dried in an oven at 120°C for 24 hours, and then calcined at 500°C for 8 hours to obtain a catalyst sample.

Embodiment 2

[0019] The preparation process is the same as in Example 1, and the molar ratio of nitrate is changed to Mg:Ca:Al=19:1:10.

Embodiment 3

[0021] The preparation process is the same as in Example 1, doped with barium ions, and the molar ratio of nitrate is Mg:Ba:Al=8:1:3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com