Equipment and method for preparing isophorone through acetone gas phase condensation

A technology for isophorone and acetone, which is applied in the field of isophorone preparation by gas-phase condensation of acetone, can solve the problems of difficulty in control, unproduct separation and treatment, corrosion of equipment, etc., and achieves the advantages of saving energy consumption, reducing separation difficulty and saving costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

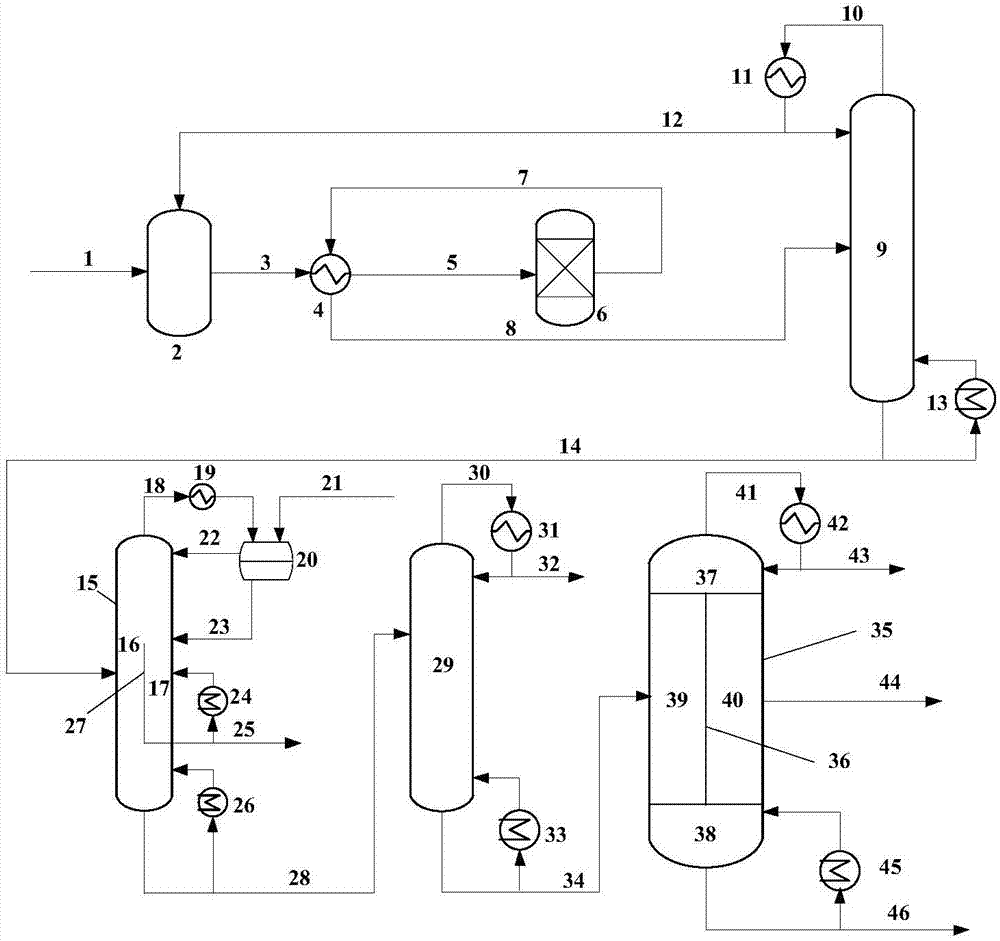

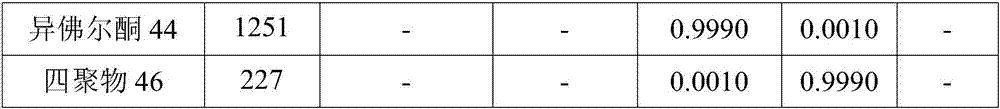

[0037] The acetone raw material 1 is heated by the vaporizer 2 and then exchanges heat with the product 7 of the fixed-bed reactor 6. After the heat exchange, the stream 5 enters the fixed-bed reactor and undergoes condensation reaction under the action of the catalyst to generate the product isophorone, and the by-product isophorone. Propylene oxide, mesitylene, tetramer and impurity water.

[0038] The stream 8 after the heat exchange between the product of the reactor and the raw material acetone enters the acetone recovery tower 9 for acetone recovery, the high-purity acetone 12 obtained at the top of the tower is recycled to the vaporizer 2 for reuse, and the mixture 14 at the bottom of the tower enters the azeotropic dividing wall tower 15 for separation.

[0039] Replenishing entrainer 21 enters in azeotropic dividing wall tower 15 tower top liquid separator tank 20, after water 25 is removed in azeotropic dividing wall tower 15, tower bottom mixture 28 enters mesityl ox...

Embodiment 2

[0047] The technical process in this embodiment is the same as that in Embodiment 1, the difference is that: n-butyl acetate is used as the entrainer, the operating pressure of the fixed bed reactor 6 is 1.0 atm, and the temperature is 335 ° C; the acetone recovery tower 9 is a filler The tower has 50 theoretical plates, the operating pressure is 1.0 atm, the temperature at the top of the tower is 45°C, and the temperature at the bottom of the tower is 80°C. The azeotropic dividing wall tower 15 is a plate tower, the number of theoretical plates in the water purification zone 17 is 16, the number of theoretical plates in the azeotropic rectification zone 16 is 42, the operating pressure is 1.2atm, and the tower top temperature is 62°C. The temperature at the bottom of the column was 83°C. The mesityl oxide column 29 is a packed column with a theoretical plate number of 35, an operating pressure of 0.25 atm, a tower top temperature of 47°C, and a tower bottom temperature of 132...

Embodiment 3

[0052] The process flow of this embodiment is the same as that of Embodiment 1, except that: isobutyl formate is used as the entrainer, the operating pressure of the fixed-bed reactor 6 is 3.5 atm, and the temperature is 360°C. The acetone recovery tower 9 is a plate tower with a theoretical plate number of 60, an operating pressure of 2 atm, a tower top temperature of 55°C, and a tower bottom temperature of 95°C. The azeotropic dividing wall tower 15 is a plate tower, the number of theoretical plates in the water purification zone 17 is 17, the number of theoretical plates in the azeotropic rectification zone 16 is 45, the operating pressure is 2atm, and the temperature at the top of the tower is 70°C. The bottom temperature was 92°C. The mesityl oxide column 29 is a packed column with a theoretical plate number of 46, an operating pressure of 0.75 atm, a tower top temperature of 60°C, and a tower bottom temperature of 159°C. The second dividing wall tower 35 is a plate towe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com