Preparation method of isophorone

A technology of isophorone and mesityl oxide, applied in the field of basic chemical industry, can solve the problems of low conversion rate, high energy consumption, large material loss, etc., and achieve the improvement of product yield, solvent avoidance, and mild reaction process conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

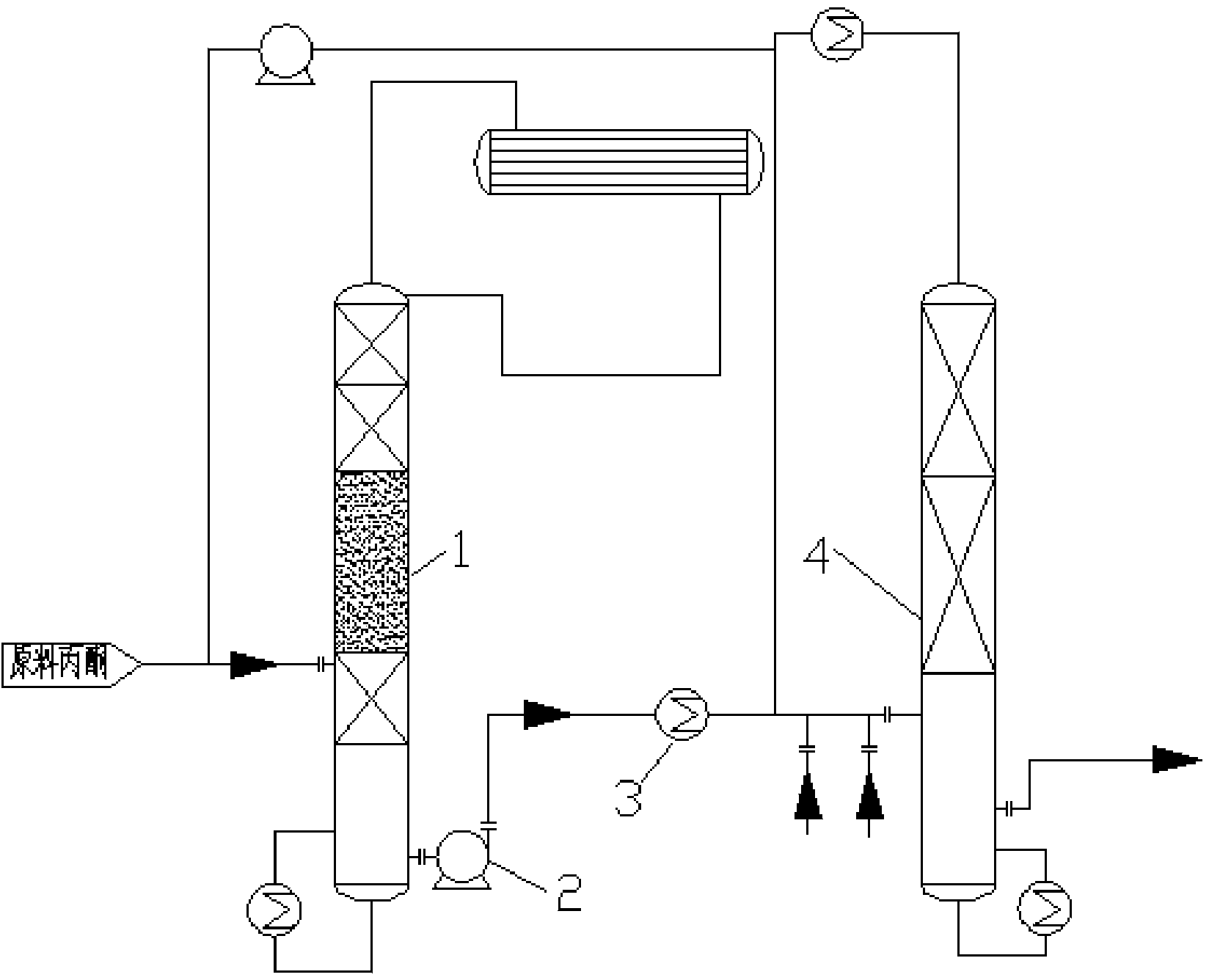

[0026] The invention provides a kind of preparation method of isophorone, comprises the following steps:

[0027] (1) Acetone is continuously fed into the first reaction tower 1 for condensation reaction to generate diacetone alcohol mixed liquid;

[0028] (2) After the diacetone alcohol mixture flows out of the first reaction tower 1, it flows into the heat exchanger 3 through the feed pump 2 and heats up to cause a dehydration reaction of diacetone alcohol to generate a mixture of acetone and mesityl oxide;

[0029] (3) Put the mixture of acetone and mesityl oxide and the rest of the diacetone alcohol mixture together with the catalyst into the second reaction tower 4 for reaction, and after cooling the prepared reaction liquid, separate the gas phase , an oil phase and an aqueous phase, the oil phase is an isophorone synthetic liquid; and

[0030] (4) The isophorone synthesis solution is neutralized and rectified to obtain the finished isophorone.

[0031] In order to mak...

Embodiment 1

[0053] see figure 1 , figure 1 It is a schematic diagram of equipment for a preparation method of isophorone of the present invention. Such as figure 1 As shown, under continuous steady-state conditions, acetone at 1m 3 The flow rate of / h is continuously sent to the first reaction tower 1, and the acetone is heated and vaporized by the heat exchanger of the first reaction tower 1, and the condensation reaction occurs in the stripping section to the reaction section to generate diacetone alcohol, and the unreacted acetone continues to pass through the rectification section It is condensed by the top condenser and returned to the first reaction tower 1 to continue the reaction. The diacetone alcohol produced by the reaction has a high boiling point and is easy to dehydrate to generate mesityl oxide, and it will gradually go down to the bottom of the tower to enrich. After a period of reaction, the content of diacetone alcohol at the bottom of the tower and the mesityl oxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com