Production technology for isophorone

A technology of isophorone and production process, applied in the field of isophorone production process, can solve the problems of high production cost and high energy consumption, achieve good energy saving effect, simple production process, easy to safe and stable production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

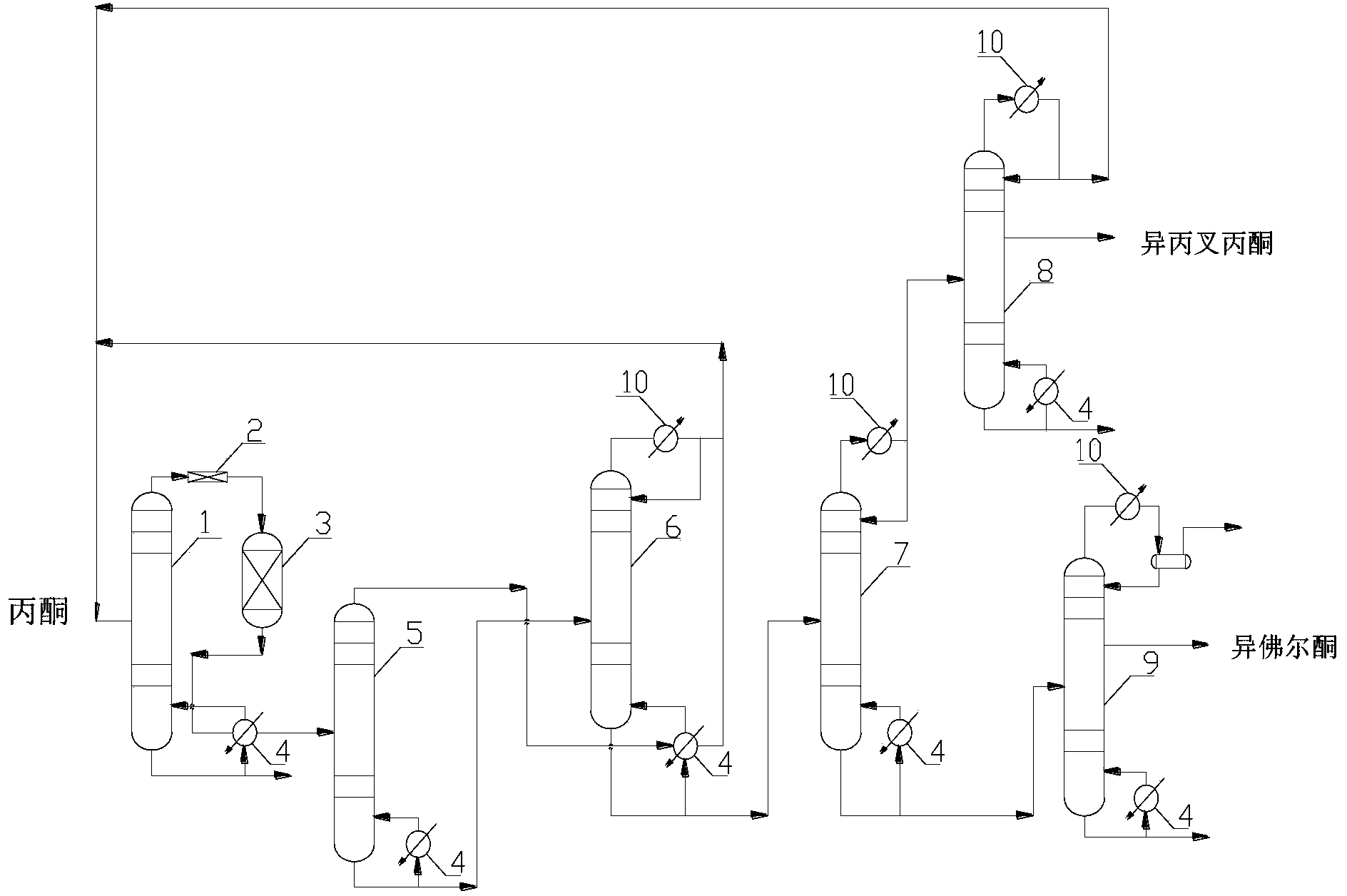

Method used

Image

Examples

Embodiment 1

[0036] The first step, acetone vaporization and heating

[0037] The acetone liquid with a flow rate of 10000kg / h is first poured into the vaporization tower 1 for vaporization, the vaporization temperature is 58°C, and then heated to 200°C through the heating furnace 2;

[0038] The second step, acetone polycondensation reaction

[0039] The acetone gas that is vaporized and heated through the first step is sent into the fixed-bed reactor 3 that is equipped with a magnesium-calcium-aluminum solid basic catalyst whose composition is the molar ratio of Mg / Ca / Al=8:1:8. The fixed bed reactor is filled with polycondensation reaction, the reaction temperature is 200°C, the reaction pressure is 100KPa, and the reaction products are mainly water, mesityl oxide, isomers of mesityl oxide, mesitylene, isophorone and tetramerization products mixture;

[0040] The third step, recovery of acetone

[0041] The reaction product obtained through the acetone polycondensation reaction in the...

Embodiment 2

[0049] The first step, acetone vaporization and heating

[0050] The acetone liquid with a flow rate of 8000kg / h is first poured into the vaporization tower 1 for vaporization, the vaporization temperature is 80°C, and then heated to 300°C through the heating furnace 2;

[0051] The second step, acetone polycondensation reaction

[0052] The acetone gas that is vaporized and heated through the first step is sent into the fixed-bed reactor 3 that is equipped with a magnesium-calcium-aluminum solid basic catalyst whose composition is the molar ratio of Mg / Ca / Al=8:1:8. The fixed bed reactor is filled with polycondensation reaction. The reaction temperature is 300°C and the reaction pressure is 250KPa. The reaction products are mainly water, mesityl oxide, isomers of mesityl oxide, mesitylene, isophorone and tetramerization products. mixture;

[0053] The third step, recovery of acetone

[0054] The reaction product obtained through the acetone polycondensation reaction in the ...

Embodiment 3

[0062] The first step, acetone vaporization and heating

[0063] The acetone liquid with a flow rate of 12000kg / h is first poured into the vaporization tower 1 for vaporization, the vaporization temperature is 100°C, and then heated to 350°C through the heating furnace 2;

[0064] The second step, acetone polycondensation reaction

[0065] The acetone gas that is vaporized and heated through the first step is sent into the fixed-bed reactor 3 that is equipped with a magnesium-calcium-aluminum solid basic catalyst whose composition is the molar ratio of Mg / Ca / Al=8:1:8. The fixed bed reactor is filled with polycondensation reaction, the reaction temperature is 350°C, the reaction pressure is 500KPa, and the reaction products are mainly water, mesityl oxide, isomers of mesityl oxide, mesitylene, isophorone and tetramerization products mixture;

[0066] The third step, recovery of acetone

[0067]The reaction product obtained through the acetone polycondensation reaction in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com