Method for preparing diacetone acrylamide from temperature-controlled phase-change type heteropoly acid ionic liquid catalyst

A technology of diacetone acrylamide and ionic liquid, which is applied in the field of compound preparation, can solve the problems of less acidic group content, complicated process, difficult to reuse, etc., and achieves the effects of improving selectivity, simple process purification, and solving difficult separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Preparation of temperature-controlled phosphotungstic acid ionic liquid catalyst:

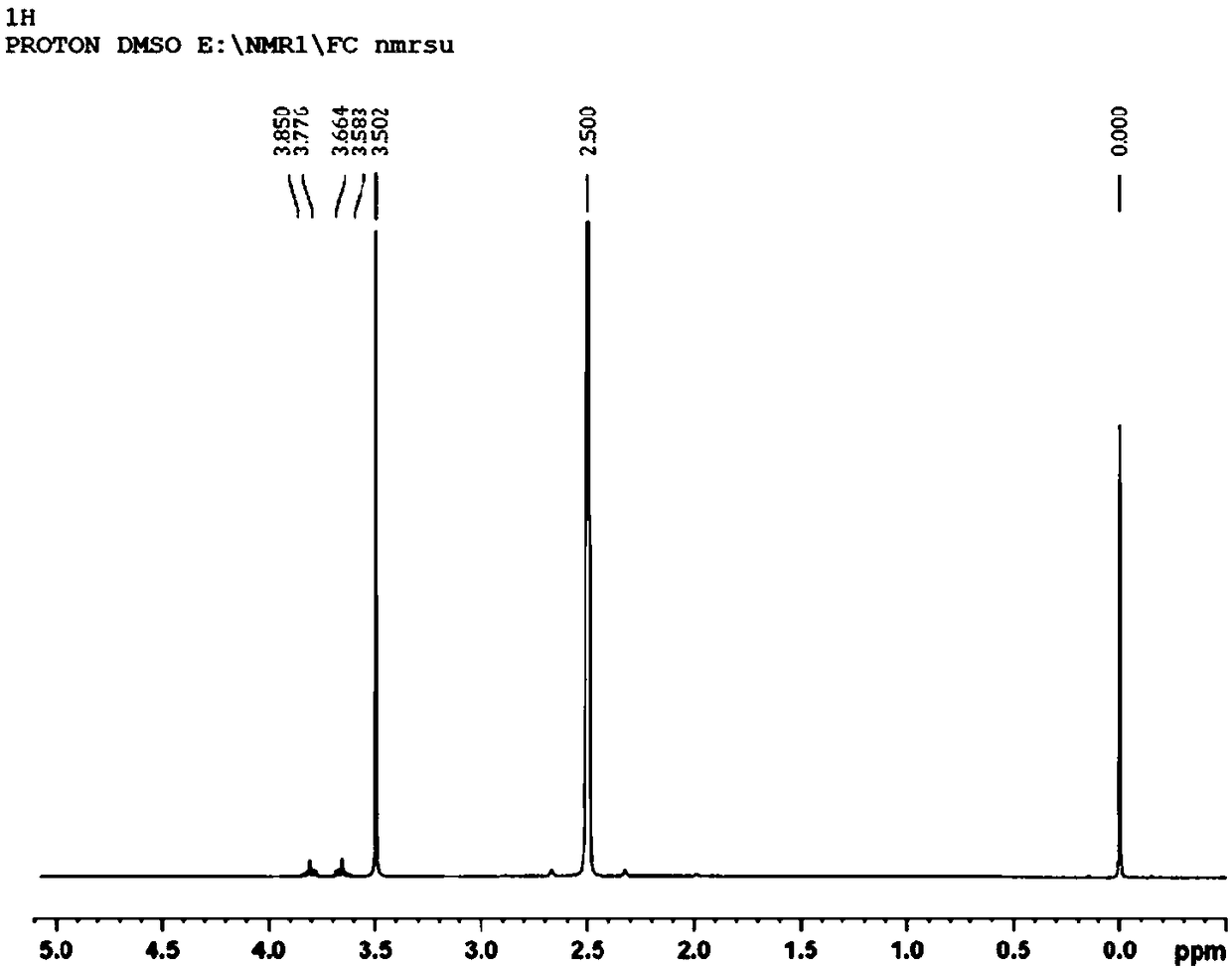

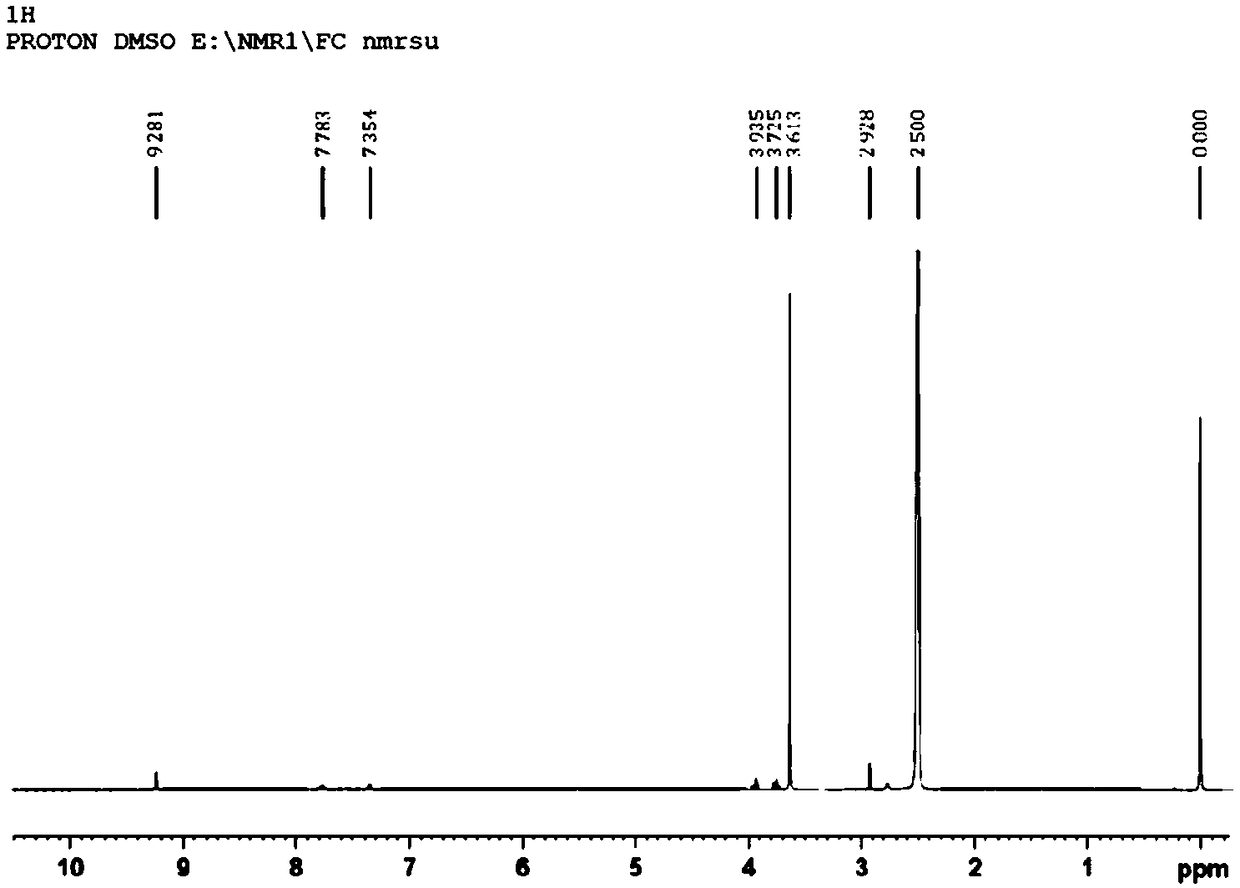

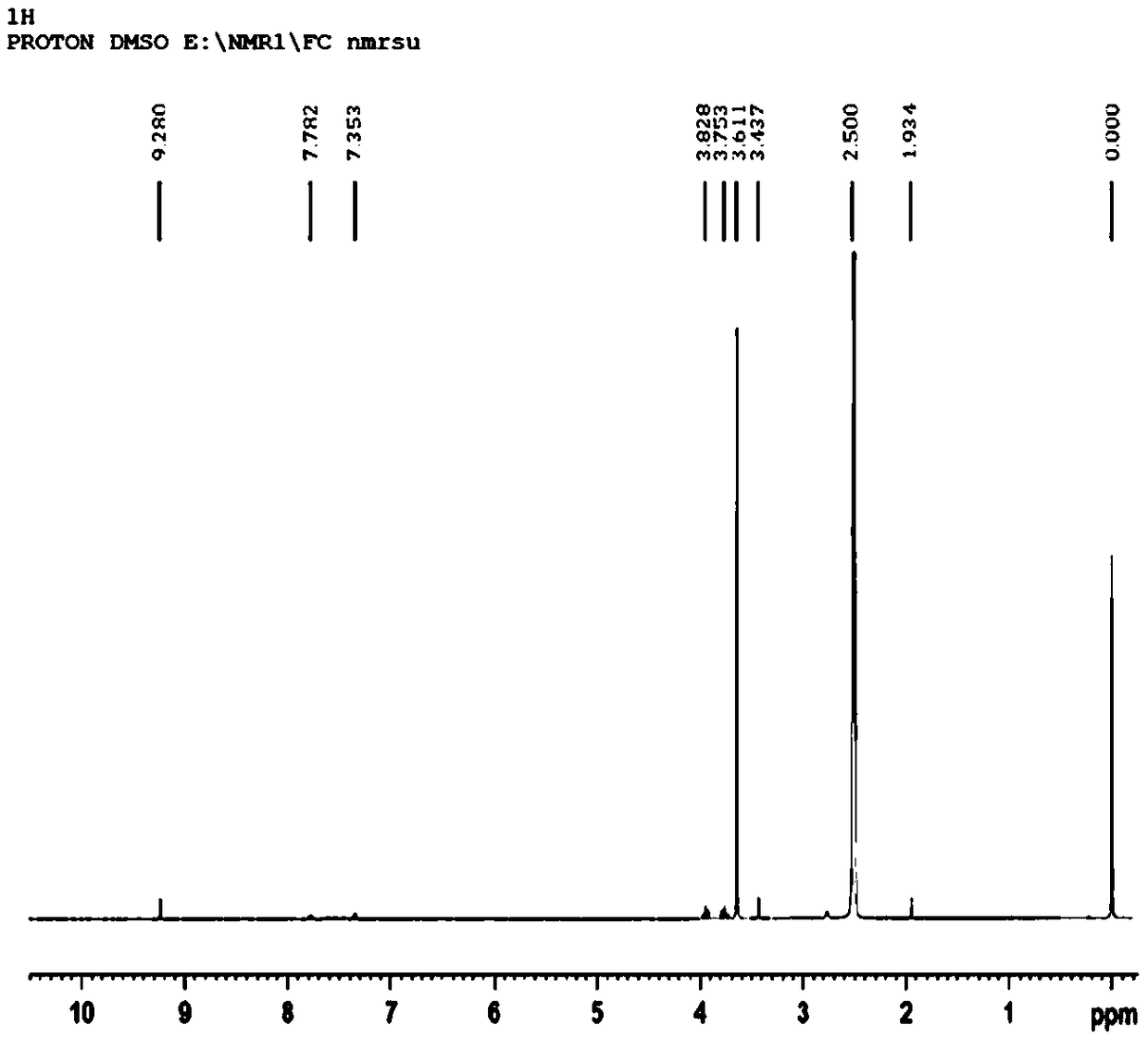

[0052] (1) Dissolve 30mmol of polyethylene glycol with molecular weight n=15 in toluene to make a polyethylene glycol solution, which is designated as solution 1; dissolve 60mmol of thionyl chloride and 60mmol of pyridine in toluene to make a solution, which is designated as Solution 2. Slowly add solution 1 dropwise to solution 2 under nitrogen atmosphere, and react at 70°C for 3 hours. After the reaction is completed, the solid is obtained by suction filtration, and washed with a small amount of sodium bicarbonate to neutralize the generated acidic substance. Compound 2 is obtained after suction filtration. Weighing 21.7g, the yield of this step is 90%.

[0053] (2) Dissolve 25mmol of compound 2 and 60mmol of nitrogen methyl imidazole in acetonitrile and react at 70°C for 24h. After rotary evaporation, compound 3 was obtained and weighed to obtain 20.4g. The yield of this step was 84%...

Embodiment 2

[0057] Weigh 0.3mol of acrylamide and 3mol of mesityl oxide, pour them into a three-necked flask, stir evenly, then weigh about 8mmol of phosphotungstic acid ionic liquid catalyst and pour them into the flask, and add 1.6mmol of potassium phosphotungstate solid to the flask Put it in an oil bath at 70°C, react for 6 hours, stop the reaction, wait for the reaction liquid to cool below 20°C and filter to separate the solid potassium phosphotungstate, separate the liquid phase after standing still, take the upper liquid for liquid chromatography analysis, and calculate Yield and selectivity, the results are shown in Table 1. The analytical instrument is WatersH-class produced by Waters Corporation, the chromatographic column is HSST3 (4.6×250mm) 5 μm, the mobile phase is acetonitrile / water, and the gradient elution method is adopted, the column temperature is 40 °C, and the flow rate of the mobile phase is 1.0ml / min. The detector is a PDA detector. Subsequent purification is car...

Embodiment 3

[0068] Weigh 0.1mol acrylamide and 1.1mol mesityl oxide, pour into a three-necked flask and stir evenly, then weigh 5.4mmol phosphotungstic acid ionic liquid catalyst and pour it into the flask, add 1.2mmol ammonium phosphotungstate, put the flask Put it into a 70°C oil bath, react for 6 hours, stop the reaction, and filter out the solid ammonium phosphotungstate after the reaction liquid is cooled to below 20°C. rate and selectivity. After washing and drying the catalyst in the lower layer repeatedly with acetone, the recovery rate was calculated after weighing and used for the next reaction. The reaction step of Example 3 was repeated five times, wherein the reacted catalyst was repeatedly used 5 times. Diacetone acrylamide yield and selectivity and catalyst recovery calculation method are with embodiment 2.

[0069] According to above-mentioned embodiment operation, the rate of recovery of catalytic effect and catalyst is shown in the following table:

[0070] Table 2

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com