Heterogeneous catalyst for preparing isophorone, preparation and applications thereof

A heterogeneous catalyst and isophorone technology, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, carbon-based compound preparation, etc., can solve problems such as decline and low conversion rate, Achieve the effects of simple preparation method, high activity and selectivity, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

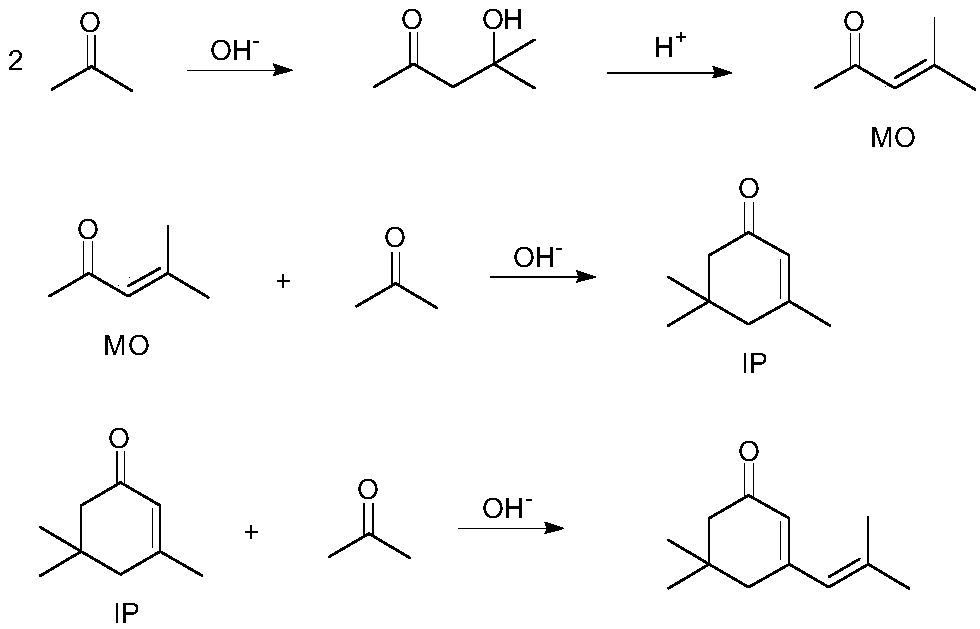

Problems solved by technology

Method used

Image

Examples

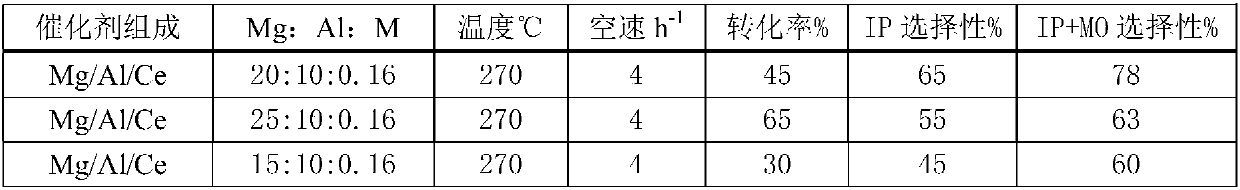

Embodiment 1

[0038] The nitrate is prepared in a mixed salt solution according to the molar ratio Mg:Al:Ce=20:10:0.16. Weigh 25g magnesium nitrate hexahydrate, 18.29g aluminum nitrate nonahydrate, 0.43g cerium ammonium nitrate, and dissolve them in 100ml distilled water , Add 1 gram of hexamethylene tetramine and 1 gram of amantadine as the template agent; at the same time configure lye: add 9.35 grams of NaOH and 6.36 grams of Na 2 CO 3 Dissolve in 50ml of water to obtain a precipitate. At 80°C, drop the precipitant into the mixed salt solution, the pH of the mixed solution is 8-9, continue to stir for 5 hours and then stand for 12 hours. The mixed solution was filtered, washed with water three times, and the filter cake was dried at 120°C for 12 hours and calcined at 550°C for 5 hours. The above catalyst is used in the reaction of acetone condensation to prepare isophorone, a fixed bed reactor is used, and 3 grams of catalyst are loaded. Under normal pressure, pump acetone into the syste...

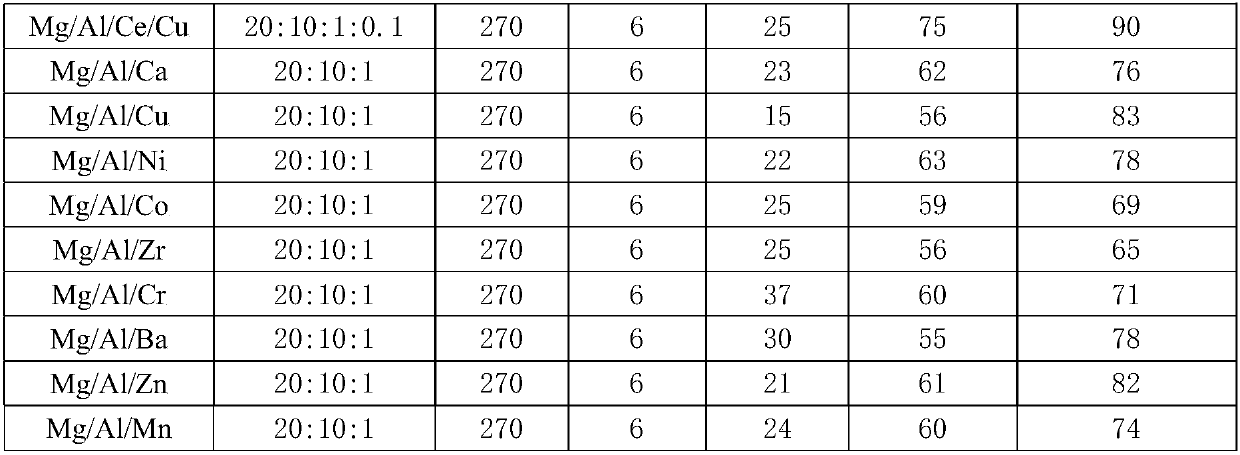

Embodiment 2

[0040] The nitrate is prepared according to the molar ratio of Mg:Al:Ce:Cu=20:10:0.16:0.1 to prepare a mixed salt solution, weigh 25g magnesium nitrate hexahydrate, 18.29g aluminum nitrate nonahydrate, 0.43g cerium ammonium nitrate, 0.2g nitric acid Copper, dissolve it in 100ml of distilled water, add 1g of stencil agent hexamethylenetetramine and 1g of octadecyltrimethylammonium chloride; at the same time, configure lye: add 9.35g of NaOH and 6.36g of Na 2 CO 3 Dissolve in 50ml of water to obtain a precipitate. At 80°C, drop the precipitant into the mixed salt solution, the pH of the mixed solution is 8-9, continue to stir for 5 hours and then stand for 12 hours. The mixed solution was filtered, washed with water three times, and the filter cake was dried at 120°C for 12 hours and calcined at 600°C for 5 hours. The above catalyst is used in the reaction of acetone condensation to prepare isophorone, a fixed bed reactor is used, and 3 grams of catalyst are loaded. Under normal...

Embodiment 3

[0042] Prepare the mixed salt solution according to the molar ratio of Mg:Al:Ce:Cu=20:10:1:0.1 for nitrate, weigh 25g magnesium nitrate hexahydrate, 18.29g aluminum nitrate nonahydrate, 2.67g cerium ammonium nitrate, 0.2g nitric acid Dissolve copper in 100ml of distilled water, add 1g of stencil agent hexamethylenetetramine and 1g of tetraethylammonium hydroxide; also configure lye: add 8.88g NaOH and 6.04g Na 2 CO 3 Dissolve in 50ml of water to obtain a precipitate. At 80°C, drop the precipitating agent into the mixed salt solution, the pH of the mixed solution is 7-8, continue to stir for 5 hours and then stand for 12 hours. The mixed solution was filtered, washed with water three times, and the filter cake was dried at 120°C for 12 hours and calcined at 650°C for 5 hours. The above catalyst is used in the reaction of acetone condensation to prepare isophorone, a fixed bed reactor is used, and 3 grams of catalyst are loaded. Under normal pressure, pump acetone into the syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com