Device for extracting mesityl oxide from dilute acetone solution

A technology of mesityl oxide and acetone solution, which is applied in liquid separation, separation methods, organic chemistry, etc., can solve the problems of complex operation and additional process water, and achieve the effect of reducing labor costs and preventing operational errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

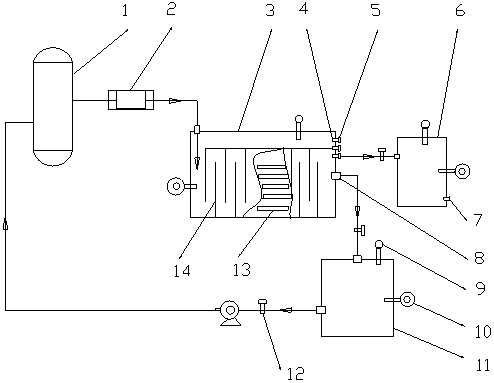

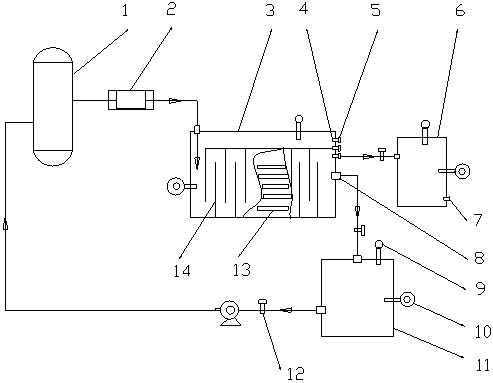

[0020] The chromatographic tank 3 contains a cooling coil 13; the side of the mesityl oxide storage tank 6 is provided with a liquid level sensor 10; the top is provided with a liquid level alarm 9, and when the liquid level exceeds a preset position, the instrument sends out a An alarm prompts the operator to open and close the valve 12; the mesityl oxide is discharged.

[0021] The transverse spacing between the flow guide baffles 14 is 50 mm.

[0022] There are 3 overflow ports A4 from top to bottom, respectively connected with bulkheads 5, the highest overflow port A4 is 6 cm higher than the overflow port B8, and the lowest overflow port A4 is 2 cm higher than the overflow port B8 , the overflow of the mesityl oxide layer of different thicknesses is realized by removing the bulkheads 5 of different heights.

[0023] The side of described diacetone storage tank 11 is respectively provided with liquid level sensor 10, measures the height of liquid level in the storage tank;...

Embodiment 2

[0025] The outer wall of the chromatographic tank 3 contains a cooling coil 13; the side of the mesityl oxide storage tank 6 is provided with a liquid level sensor 10 to measure the height of the liquid level in the storage tank; the top is provided with a liquid level alarm 9, when the liquid When the position exceeds the preset position, the instrument sends an alarm to prompt the operator to open and close the valve 12; the mesityl oxide is loaded into barrels from the mesityl oxide outlet 7.

[0026] The transverse spacing between the flow guide partitions 14 is 100mm.

[0027] There are 2 overflow ports A4 from top to bottom, respectively connected with bulkheads 5, the highest overflow port A4 is 4 cm higher than the overflow port B8, and the lowest overflow port A4 is 2 cm higher than the overflow port B8 , the overflow of the mesityl oxide layer of different thicknesses is realized by removing the bulkheads 5 of different heights.

[0028] The said propylene ketone st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal spacing | aaaaa | aaaaa |

| Horizontal spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com