Double-metal-sulfide catalyst with high hydrodeoxygenation activity and preparation method thereof

A hydrodeoxygenation and catalyst technology, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem that the bimetallic synergy cannot get the maximum effect, and achieve excellent catalytic activity. High hydrodeoxygenation activity and effect of increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

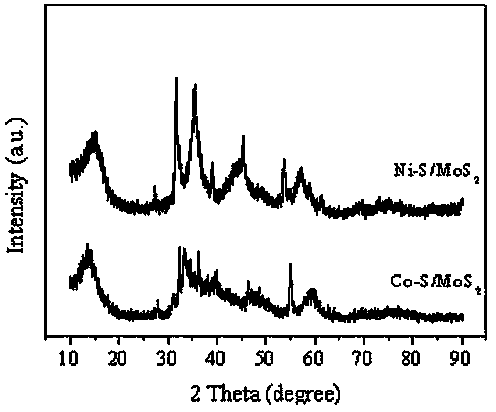

[0030] Dissolve 1.39g of ammonium molybdate in 150ml of deionized water, add 1.81g of thiourea and stir to dissolve, then pour it into a 300ml reaction kettle, close the lid of the kettle, stir and mix, react at 200°C for 12 hours, cool down to 40°C, and open the reaction cauldron lid. Dissolve 0.17g of nickel nitrate in 30ml of deionized water, add 0.08g of thiourea to dissolve, then add this solution into the previously opened reaction kettle, close the lid of the kettle, stir and mix at 300r / min, and react at 200°C for 12 hours. After the reaction, a black precipitate was obtained, which was washed with water and alcohol, and dried in a vacuum oven at 40° C. for 5 hours.

[0031] Add 86.5 g of n-dodecane, 13.5 g of p-cresol and 0.60 g of the catalyst prepared above in the autoclave. Raise to 300°C, adjust the rotation speed to 900r / min, hydrogen pressure to 4.0MPa, and continue the reaction for 6 hours. The product was analyzed by Agilent 6890 / 5973N GC-MS, and the conversi...

Embodiment 2

[0033] Dissolve 1.39g of ammonium molybdate in 150ml of deionized water, add 1.81g of thiourea and stir to dissolve, then pour it into a 300ml reaction kettle, close the lid of the kettle, stir and mix, react at 200°C for 12 hours, cool down to 50°C, and open the reaction cauldron lid. Dissolve 0.50g of nickel nitrate in 30ml of deionized water, add 0.23g of thiourea to dissolve, then add this solution into the previously opened reaction kettle, close the lid of the kettle, stir and mix at 300r / min, and react at 200°C for 12 hours. After the reaction, a black precipitate was obtained, which was washed with water and alcohol, and dried in a vacuum oven at 40° C. for 5 hours.

[0034] Add 86.5 g of n-dodecane, 13.5 g of p-cresol and 0.60 g of the catalyst prepared above in the autoclave. Raise to 300°C, adjust the rotation speed to 900r / min, hydrogen pressure to 3.0MPa, and continue the reaction for 6 hours. The product was analyzed by Agilent 6890 / 5973N GC / MS, and the conversi...

Embodiment 3

[0036] Dissolve 1.39g of ammonium molybdate in 150ml of deionized water, add 1.81g of thiourea and stir to dissolve, then pour it into a 300ml reaction kettle, close the lid of the kettle, stir and mix, react at 200°C for 12 hours, cool down to 50°C, and open the reaction The cauldron should. Dissolve 0.50g of cobalt nitrate in 30ml of deionized water, add 0.23g of thiourea to dissolve, then add this solution into the previously opened reaction kettle, close the lid of the kettle, stir and mix at 300r / min, and react at 200°C for 12 hours. After the reaction, a black precipitate was obtained, which was washed with water and alcohol, and dried in a vacuum oven at 40° C. for 5 hours.

[0037] Add 86.5 g of n-dodecane, 13.5 g of p-cresol and 0.10 g of the catalyst prepared above in the autoclave, install the high-pressure reaction device, remove the air in the autoclave, and then rise from room temperature at a rate of 10 °C / min. To 250°C, adjust the rotation speed to 900r / min, h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com