Method of producing chlorinated paraffin-70 through low temperature catalysis

A technology of chlorinated paraffin and low-temperature catalysis, which is applied in the chemical/physical/physicochemical process of energy application, petrochemical modification, etc. It can solve the problems of many production equipment, waste acid generation, poor product quality, etc., and avoid color Effects of deepening, lowering reaction temperature, lowering energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

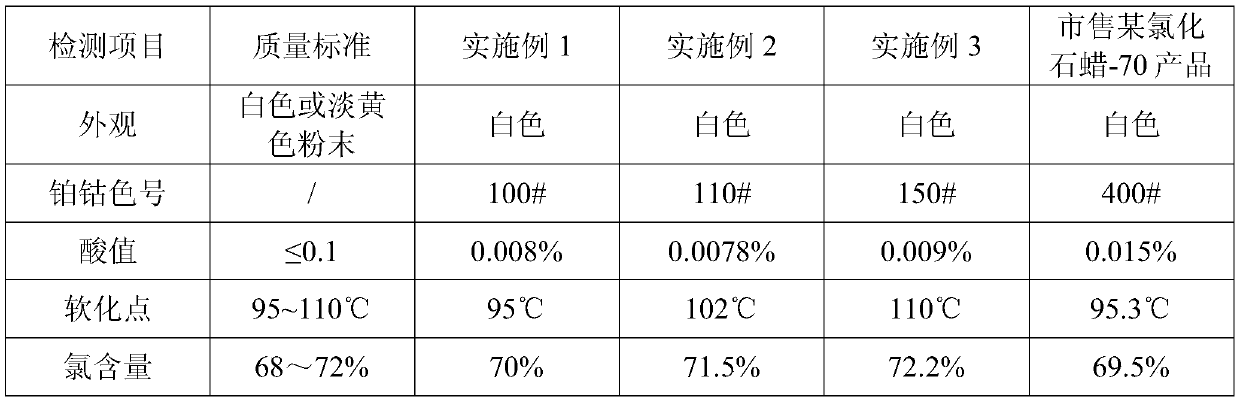

Embodiment 1

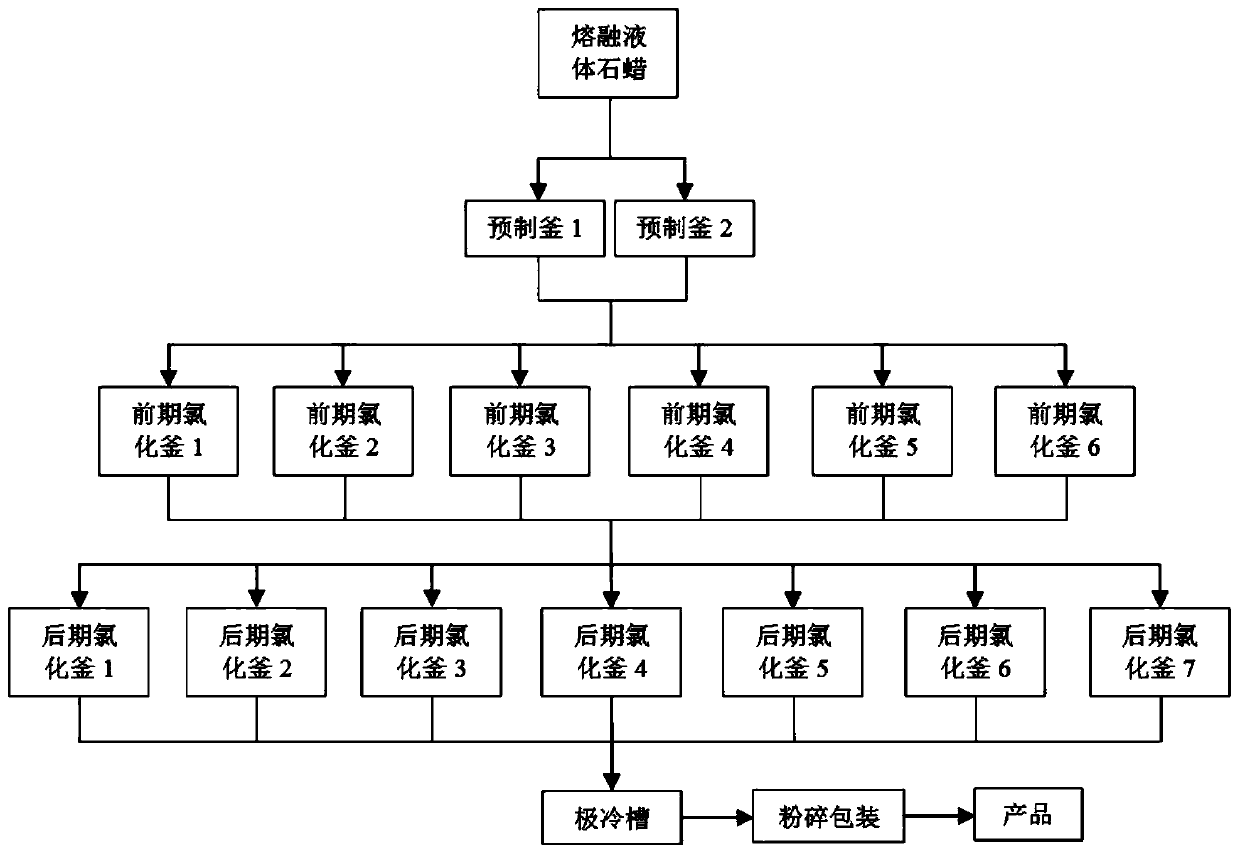

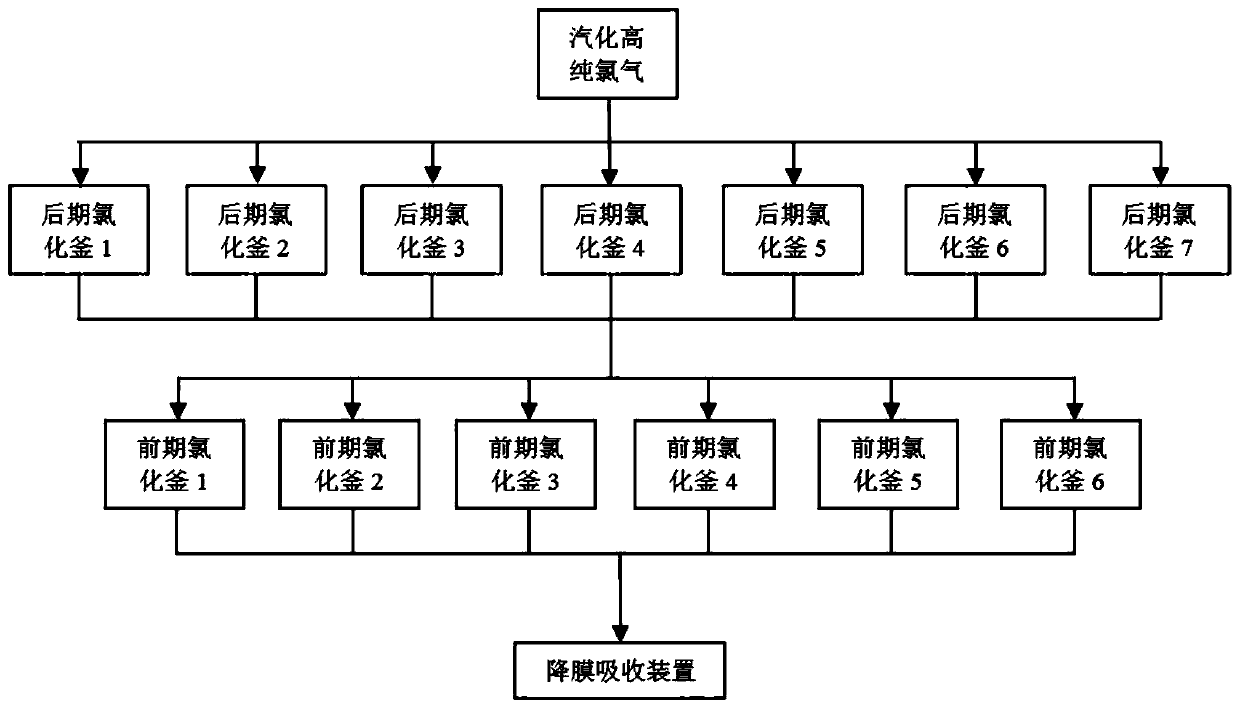

[0050] A method for low-temperature catalytic production of chlorinated paraffin-70, the specific preparation steps are as follows:

[0051] (1) Put 1400kg of solid paraffin into the reaction kettle, heat up to 100° C. to melt the solid paraffin; after the solid paraffin is completely melted, press it into the prefabricated kettle for light-induced reaction to obtain liquid paraffin;

[0052] (2) in the liquid paraffin of step (1), add 1.5kg azobisisobutyronitrile and 1.5kg N, N-dimethylaniline;

[0053] (3) the reaction solution in the step (2) is transferred to the early stage chlorination kettle, feeds chlorine, and carries out the early stage chlorination reaction, until the chlorine content of the chlorinated paraffin in the early stage chlorination kettle reaches 36%, gets the early stage chlorinated paraffin liquid ;

[0054] (4) the chlorinated paraffin liquid in the earlier stage gained in the step (3) is transferred to the later stage chlorination kettle, feeds chlo...

Embodiment 2

[0058] A method for low-temperature catalytic production of chlorinated paraffin-70, the specific preparation steps are as follows:

[0059] (1) Put 1400kg of solid paraffin into the reaction kettle, heat up to 110° C. to melt the solid paraffin; after the solid paraffin is completely melted, press it into the prefabricated kettle for light-induced reaction to obtain liquid paraffin;

[0060] (2) in the liquid paraffin of step (1), add 1.5kg azobisisobutyronitrile and 1.5kg N, N-dimethylaniline;

[0061] (3) the reaction solution in the step (2) is transferred to the early stage chlorination kettle, feeds chlorine, and carries out the early stage chlorination reaction, until the chlorine content of the chlorinated paraffin in the early stage chlorination kettle reaches 36%, gets the early stage chlorinated paraffin liquid ;

[0062] (4) the chlorinated paraffin liquid in the earlier stage gained in the step (3) is transferred to the later stage chlorination kettle, feeds chlo...

Embodiment 3

[0066] A method for low-temperature catalytic production of chlorinated paraffin-70, the specific preparation steps are as follows:

[0067] (1) Put 1400kg of solid paraffin into the reaction kettle, heat up to 100° C. to melt the solid paraffin; after the solid paraffin is completely melted, press it into the prefabricated kettle for light-induced reaction to obtain liquid paraffin;

[0068] (2) in the liquid paraffin of step (1), add 1.0kg azobisisobutyronitrile and 1.5kg N, N-dimethylaniline;

[0069] (3) the reaction solution in the step (2) is transferred to the early stage chlorination kettle, feeds chlorine, and carries out the early stage chlorination reaction, until the chlorine content of the chlorinated paraffin in the early stage chlorination kettle reaches 36%, gets the early stage chlorinated paraffin liquid ;

[0070] (4) the chlorinated paraffin liquid in the earlier stage gained in step (3) is transferred to the later stage chlorination kettle, feeds chlorine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com