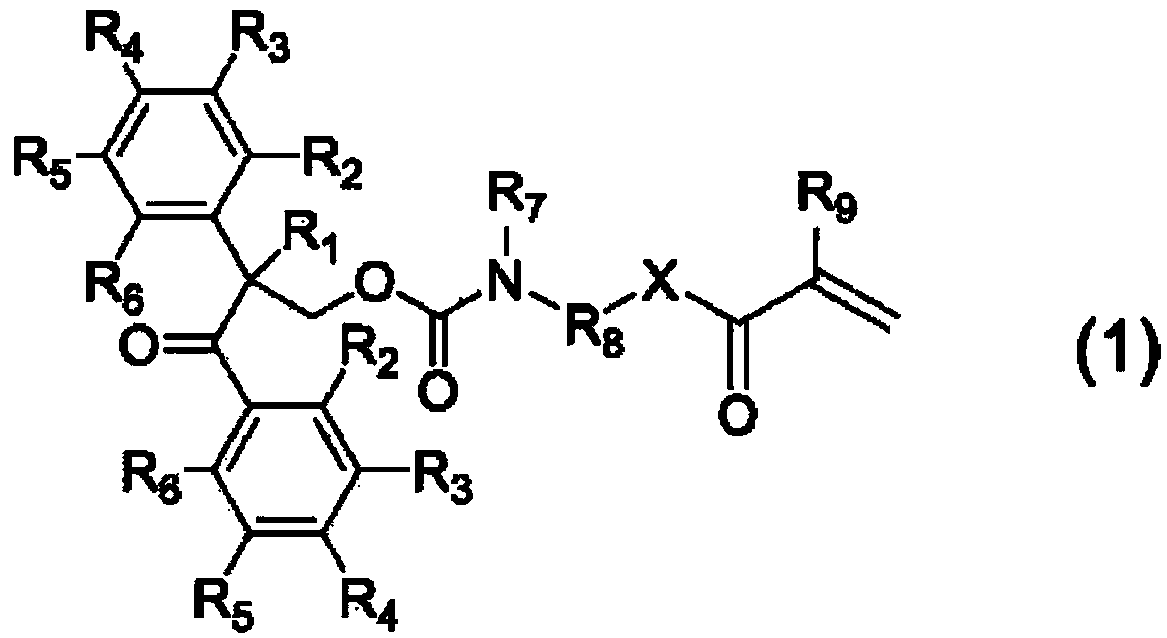

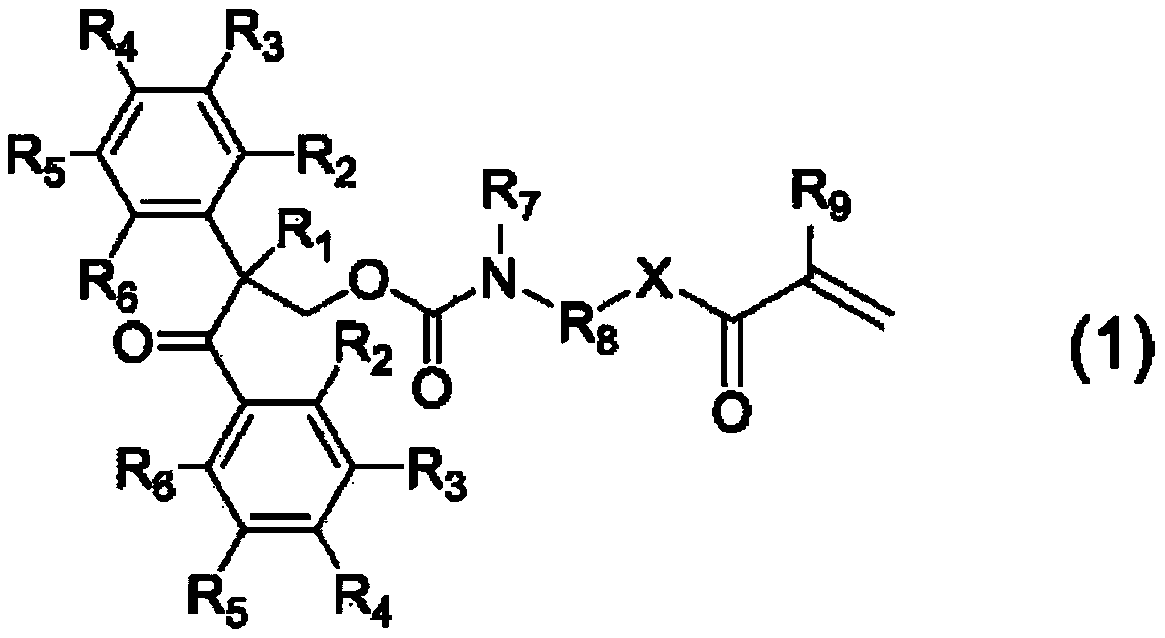

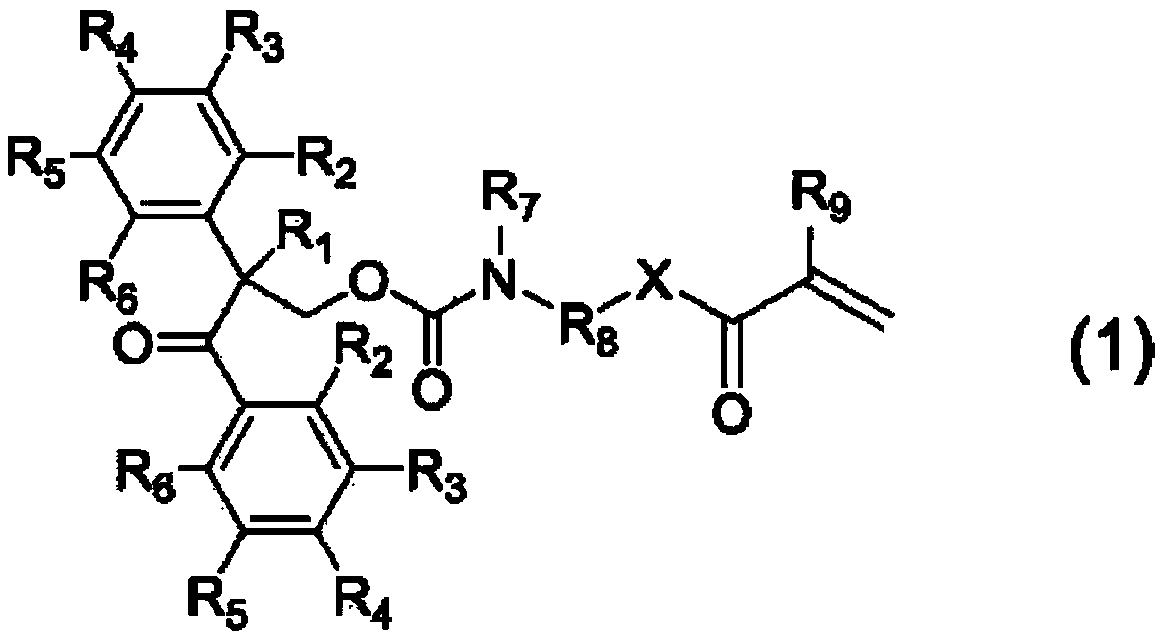

Novel compound, photopolymerization initiator containing said compound, and photosensitive resin composition containing said photopolymerization initiator

A photosensitive resin and compound technology, applied in the field of photosensitive resin compositions, can solve the problems of low quantum efficiency, unsolved nature of polyimide precursor polymerization, etc., and achieve the effect of reducing the reaction start temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0213] Synthesis of the compound shown in the formula (1) of the present invention of embodiment 1

[0214] (step 1) synthesis of the intermediate compound shown in formula (31)

[0215] After adding and dissolving 10 parts of water and 53 parts of ethanol to 1.9 parts of potassium cyanide, ultrasonic treatment was performed in a nitrogen atmosphere to degas the reaction liquid. 10 parts of 4-(methylthio)benzaldehyde represented by following formula (30) was dripped at this solution, and it heated to 80 degreeC and started reaction. After stirring for 30 minutes, the reaction liquid was cooled to 3° C., and the precipitated crystals were recovered by suction filtration. The recovered crystals were purified by recrystallization using a large amount of ethanol to obtain 7.6 parts of an intermediate compound represented by the following formula (31).

[0216]

[0217] (step 2) synthesis of the intermediate compound shown in formula (32)

[0218] In a flask equipped with a s...

Embodiment 2

[0223] Synthesis of the compound shown in the formula (1) of the present invention in embodiment 2

[0224] (Step 4) Synthesis of the compound (photopolymerization initiator C-2) of the present invention represented by the following formula (C-2)

[0225] Except for using 2-acryloyloxyethyl isocyanate (KarenzAOI manufactured by Hedenko Co., Ltd.) to replace 2-methacryloyloxyethyl isocyanate, the rest are obtained in the same manner as step 3 to obtain the following formula (C-2) The represented compound of the present invention (initiator C-2) is 6.4 parts.

[0226]

Embodiment 3 and 4、 comparative example 2 to 5

[0238] (Examples 3 and 4, Comparative Examples 2 to 5 preparation of photosensitive resin composition)

[0239] Each component was mixed according to the compounding quantity shown in Table 2, and the photosensitive resin composition was obtained.

[0240] (Curing test of photosensitive resin composition)

[0241] After coating the photosensitive resin compositions of Examples 3 and 4 and Comparative Examples 2 to 5 on the Si substrate by spin coating, they were dried by prebaking (PREBAKE) at 100°C for 2 minutes on a hot plate to obtain a film thickness 10 μm resin composition layer. Then, exposure was performed using a high-pressure mercury lamp contact aligner (Conduct Aligner), and irradiated at 800mJ / cm 2 (365nm) UV light. Then, developing treatment was carried out by dipping method using PGMEA (23°C, 30 seconds), and the remaining film rate was evaluated by measuring the film thickness after development with a stylus type film thickness measuring device (film thicknes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com