Water-resistant modified polyvinyl alcohol coating liquid and preparation method thereof, and coating formed by coating liquid

A technology of polyvinyl alcohol and coating liquid, applied in the direction of coating, etc., can solve the problems of general material compounding, short storage period of coating liquid, insufficient coating uniformity, etc., and achieve excellent water resistance, gas barrier performance and The effect of adaptive improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

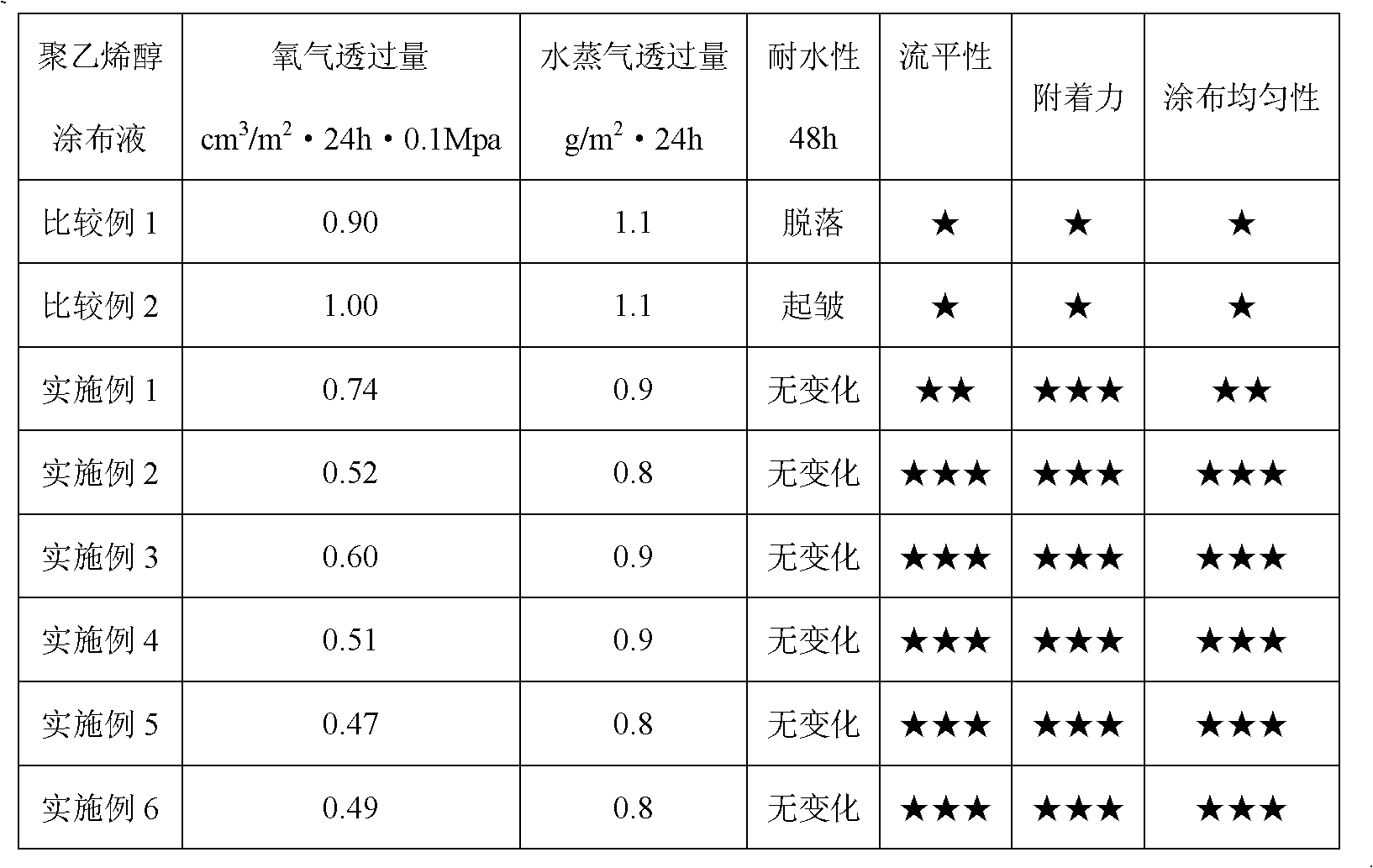

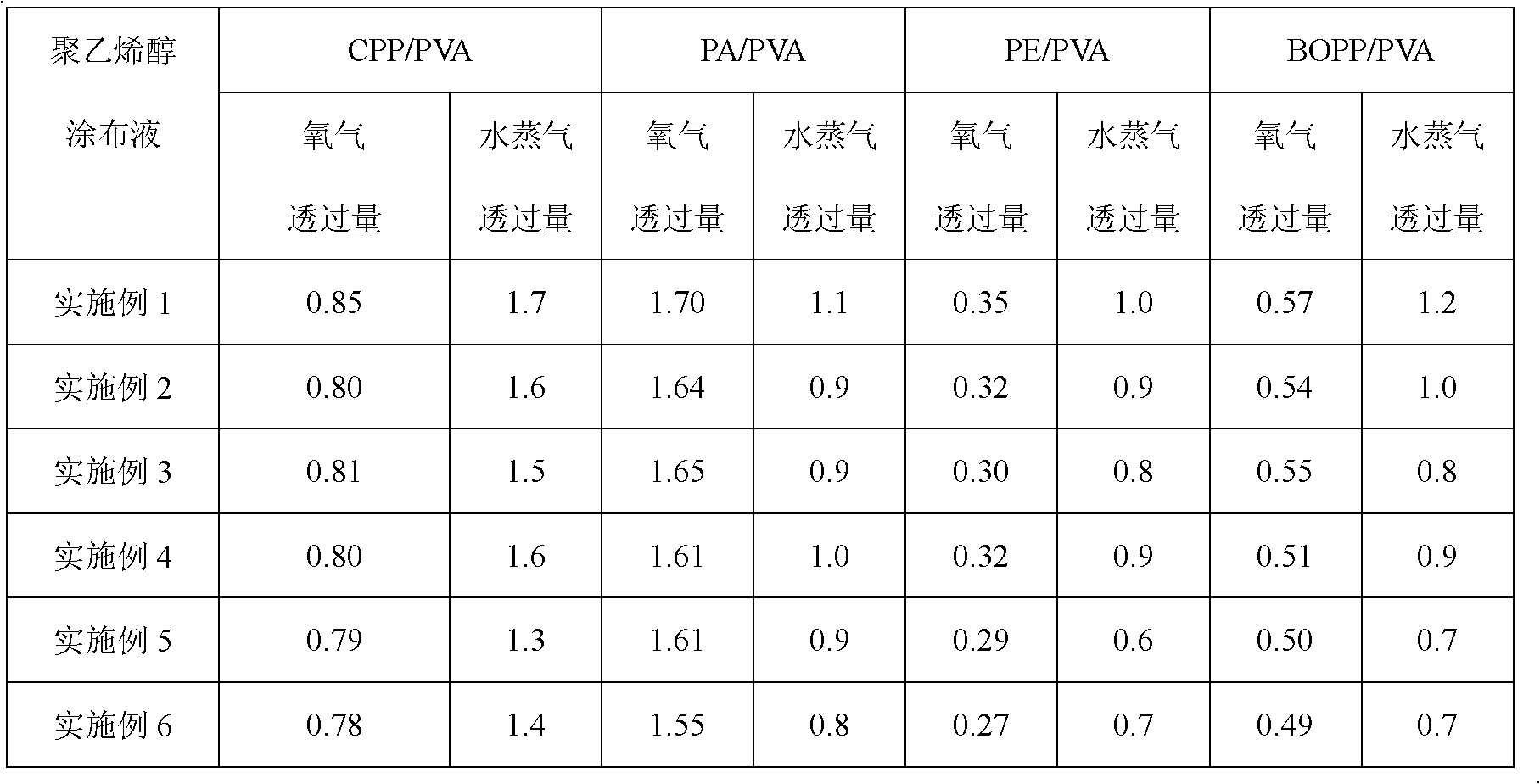

Examples

Embodiment 1

[0042] Present embodiment is by 10 parts of polyvinyl alcohol, 78 parts of water, 1 part of nano silicon dioxide, 5 parts of molecular weight is the methyl alcohol etherified melamine formaldehyde resin of 350~500, the concentration of 0.2 part is 36~38% Hydrochloric acid, 0.8 parts of coupling agent γ-glycidyl etheroxypropyl trimethoxysilane, 1.5 parts of adhesion promoter Silok628 and 5 parts of methanol. Fully dissolve the above-mentioned polyvinyl alcohol in water at 90-95°C, and add the above-mentioned ratio of nano-silica, methanol-etherified melamine-formaldehyde resin, and hydrochloric acid after the temperature drops to normal temperature; add the coupling agent γ- Glycidyl ether oxypropyltrimethoxysilane, adhesion promoter Silok628, and methanol are fully stirred and mixed to obtain a water-resistant modified polyvinyl alcohol coating liquid.

Embodiment 2

[0044]Present embodiment is by 10 parts of polyvinyl alcohol, 78 parts of water, 1 part of nano silicon dioxide, 5 parts of molecular weight is the methyl alcohol etherified melamine formaldehyde resin of 350~500, the concentration of 0.2 part is 36~38% Hydrochloric acid, 0.8 parts of coupling agent γ-glycidyl etheroxypropyl trimethoxysilane, 1.5 parts of adhesion promoter Silok628, 0.5 parts of leveling agent RM-2020 and 5 parts of methanol. Fully dissolve the above-mentioned polyvinyl alcohol in water at 90-95°C, and add the above-mentioned ratio of nano-silica, methanol-etherified melamine-formaldehyde resin, and hydrochloric acid after the temperature drops to normal temperature; add the coupling agent γ- Glycidyl ether oxypropyltrimethoxysilane, adhesion promoter Silok628, leveling agent RM-2020, and methanol are fully stirred and mixed to obtain a water-resistant modified polyvinyl alcohol coating liquid.

Embodiment 3

[0046] Present embodiment is by the polyvinyl alcohol of 6 parts, the water of 49 parts, the nano-alumina of 0.5 part, the molecular weight of 1 part is the methyl alcohol etherification melamine formaldehyde resin of 350~500, the concentration of 0.2 part is the phosphoric acid of 85%, It consists of a mixture of 0.1 part of coupling agent γ-glycidyl etheroxypropyl trimethoxysilane, 0.1 part of adhesion promoter Silok628, 0.03 part of leveling agent Silok8333 and 2 parts of methanol ethanol. Fully dissolve the above-mentioned polyvinyl alcohol in water at 90-95°C, and add the above-mentioned ratio of nano-silicon dioxide, methanol-etherified melamine-formaldehyde resin, and phosphoric acid after the temperature drops to normal temperature; add the coupling agent γ- Glycidyl ether oxypropyltrimethoxysilane, adhesion promoter Silok628, leveling agent RM-2020, and methanol are fully stirred and mixed to obtain a water-resistant modified polyvinyl alcohol coating solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| alcoholysis degree | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com